A kind of deodorizing decorative paper capable of releasing negative ions and preparation method thereof

A decorative paper and negative ion technology, applied in papermaking, paper coating, textiles and papermaking, etc., can solve environmental pollution caused by chemical volatiles, damage human health, pollute indoor environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

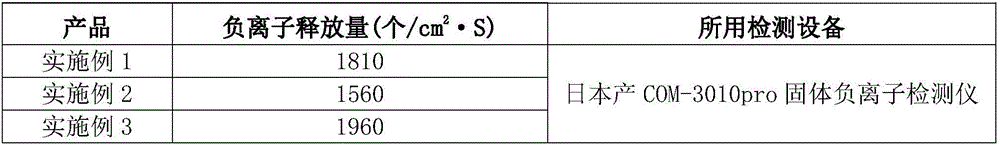

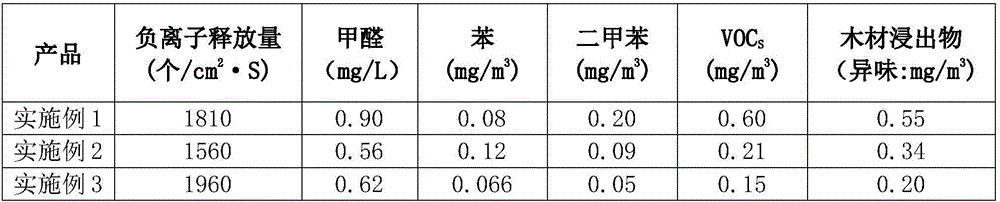

Embodiment 1

[0038] The deodorizing decorative paper capable of releasing negative ions includes a substrate layer, and a catalyst layer and an auxiliary agent layer are sequentially provided on the upper surface or the upper surface and the lower surface of the substrate layer from inside to outside,

[0039] The substrate layer is wood pulp base paper;

[0040] The catalyst layer is prepared by mixing an electric energy conversion agent and a stabilizer in a weight ratio of 1:1;

[0041] Described electrical energy conversion agent is made from the raw material of following weight: tourmaline powder 5kg, vermiculite powder 10kg, ethyl acetate 15kg, melamine resin (MF) 12kg, ion exchanger (PUES) 9kg, slow-release agent 6kg; The stabilizer Made from the following raw materials in parts by weight: monotriethanolamine phthalate 8kg, cellulose 10kg, urea-formaldehyde resin (UF) or triamine modified resin (MUF) 25kg;

[0042] The auxiliary agent layer is made of the following raw materials: 2...

Embodiment 2

[0053] The deodorizing decorative paper capable of releasing negative ions includes a substrate layer, and a catalyst layer and an auxiliary agent layer are sequentially provided on the upper surface or the upper surface and the lower surface of the substrate layer from inside to outside,

[0054] The substrate layer is wood pulp printing paper;

[0055] The catalyst layer is prepared by mixing an electric energy conversion agent and a stabilizer in a weight ratio of 1:1;

[0056] Described electrical energy conversion agent is made of the raw material of following weight: tourmaline powder 4kg, vermiculite powder 8kg, ethyl acetate 13kg, MF (melamine resin) 10kg, ion exchanger (PUES) 7kg, sustained-release agent 4kg; Made from the following raw materials in parts by weight: monotriethanolamine phthalate 6kg, cellulose 8kg; UF (urea-formaldehyde resin) or MUF (triamine-modified resin) 23kg;

[0057] The auxiliary agent layer is made of the following raw materials: 18 kg of pl...

Embodiment 3

[0068] The deodorizing decorative paper capable of releasing negative ions includes a substrate layer, and a catalyst layer and an auxiliary agent layer are sequentially provided on the upper surface or the upper surface and the lower surface of the substrate layer from inside to outside,

[0069] The substrate layer is a non-woven fabric;

[0070] The catalyst layer is prepared by mixing an electric energy conversion agent and a stabilizer in a weight ratio of 1:1;

[0071] Described electrical energy conversion agent is made of the raw material of following weight: tourmaline powder 6kg, vermiculite powder 12kg, ethyl acetate 17kg, MF (melamine resin) 14kg, ion exchanger (PUES) 11kg, sustained-release agent 8kg; Made from the following raw materials in parts by weight: monotriethanolamine phthalate 10kg, cellulose 12kg; UF (urea-formaldehyde resin) or MUF (triamine-modified resin) 27kg;

[0072] The auxiliary agent layer is made of the following raw materials: 22 kg of plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com