Nitrogen ferride/carbide co-doped composite material used for increasing high oxygen reduction activation of fuel cell cathode

A fuel cell cathode and composite material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex preparation process and difficult control of bonding degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

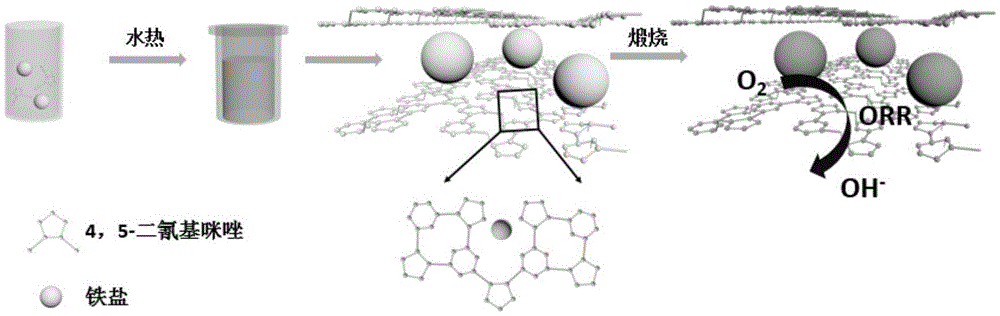

[0026] 0.6g of purchased 4,5-dicyanoimidazole was added to 10mL of N,N’-dimethylformamide solution and dissolved by ultrasonic for 10min, then 0.8g of ferrous acetate was weighed and slowly added to the above solution, and dissolved by ultrasonic for 30min. The mixed solution was added to a polytetrafluoroethylene lined autoclave. Move the autoclave to an oven and react at 120°C for 8 hours. After the reaction, the product was centrifuged and washed three times with water, and the product obtained was dried in a blast drying oven at 60°C for 8 hours. Finally at N 2 Calcining at 700℃, 800℃, 900℃ for 2h can get DCI-Fe-700, DCI-Fe-800, DCI-Fe-900.

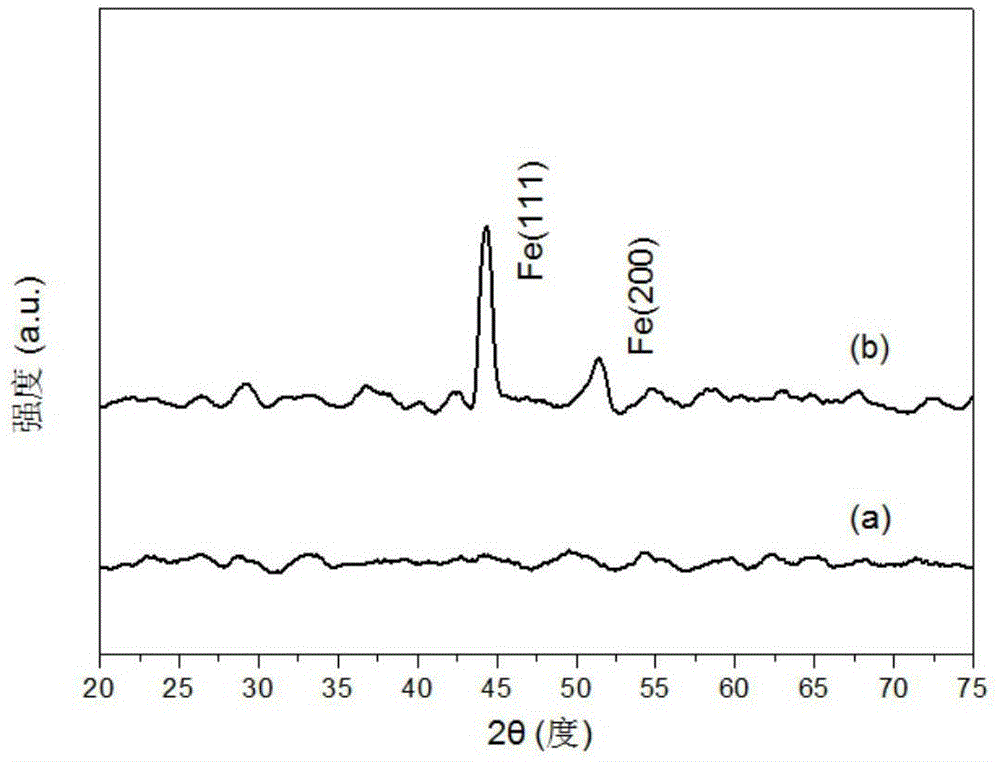

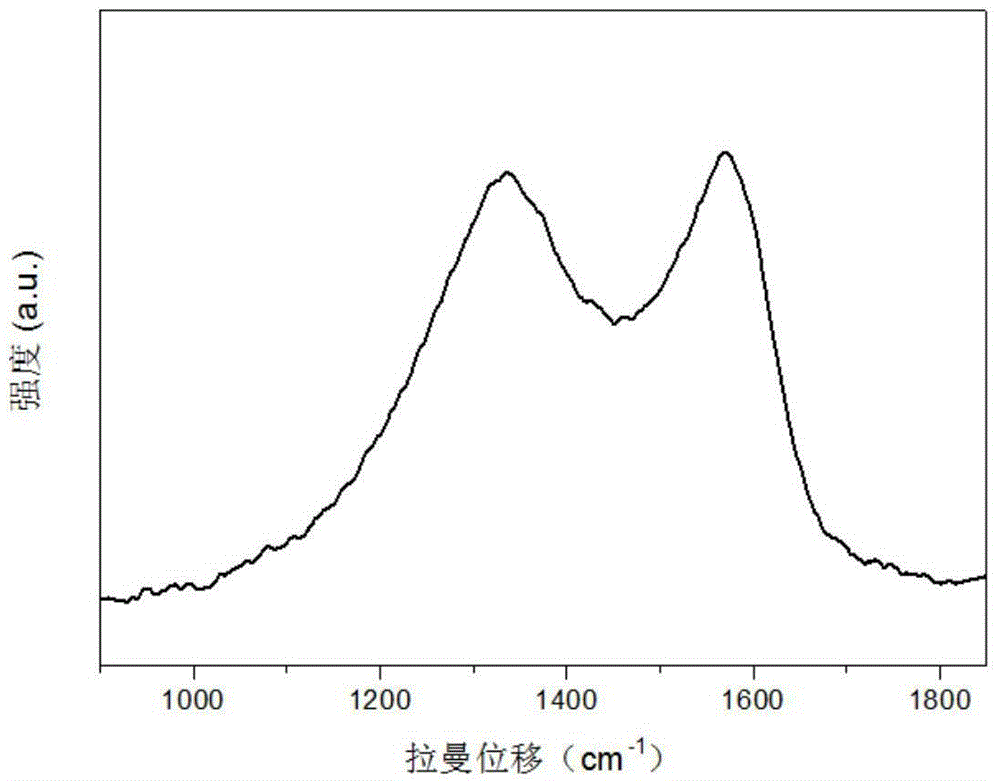

[0027] Analysis and Characterization

[0028] Analysis and characterization The structure and phase of the sample were analyzed by the Dutch X'PertPROMPD X-ray diffractometer (XRD, CuKα, λ=0.15406nm), and the carbon of the sample was tested by the German STA409PC Luxx thermogravimetric analyzer (TGA) under air atmosphere. content. Obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com