Antibacterial low-resistance high-efficiency melt-blown nonwoven fabric for air purification

A meltblown non-woven, low-resistance and high-efficiency technology, applied in non-woven fabrics, fiber types, biochemical fiber treatment and other directions, can solve the problem of not inhibiting the growth of bacteria, and achieve obvious antibacterial effect, simple process and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

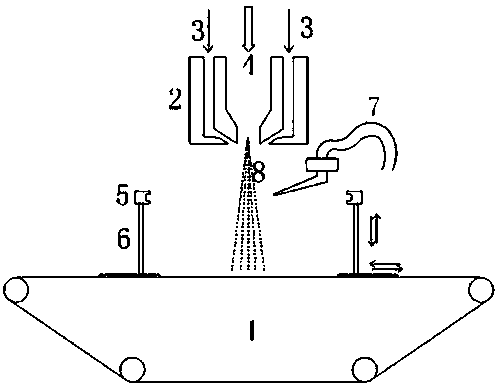

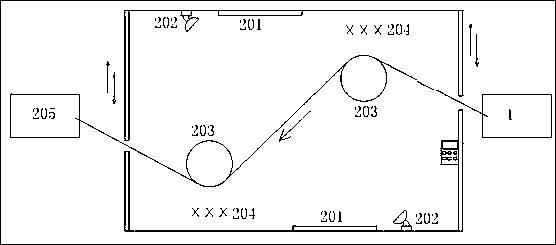

[0020] exist figure 1 , figure 2 Among them, the raw materials used in this process include polymer material slices (polypropylene slices with a melt index of 1500g / (10min)), nano-silver antibacterial agents, electret additives (zinc stearate powder), polypropylene slices and 0.5% Zinc stearate is evenly mixed and enters the melt-blown equipment. The mixture passes through the screw extruder, melt 4 filter system, metering pump, and distribution system and then reaches the spinneret. The temperature of the five areas of the screw extruder ranges from 130°C to 250°C, the temperature of the melt 4 filtration system, metering pump, and distribution system is controlled at about 250°C; the melt 4 is ejected from the spinneret under pressure, and the hot air 3 is ejected from the spinneret 2 and melts the melt 4. Drafting, the temperature of the hot air 3 is 250°C, and the speed is about 300m / s; at this time, nano-silver particles with a particle size of 1-100nm are sprayed from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com