Composite ferro-aluminum flocculant and preparation method thereof

A composite aluminum-iron and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve the problems of poor stability of flocculants, high cost, slow sedimentation rate, etc., to achieve Strong adsorption and flocculation ability, strong acid and alkali resistance, and high sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

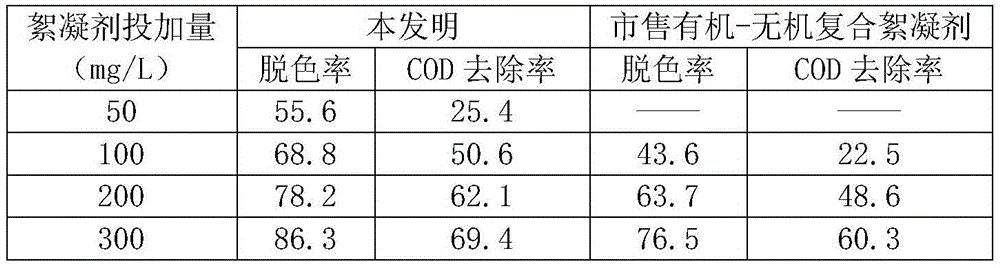

Embodiment 1

[0020] Dissolve 2 parts by weight of sodium silicate in 1000 parts by weight of water, stir well to make it into a polymeric sodium silicate solution, add dilute sulfuric acid with a concentration of 0.1mol / L dropwise to the polymeric sodium silicate solution, and make the pH of the solution down to 9. Configure the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt, wherein, the concentration of dicyandiamide is 25g / L, the concentration of quaternary ammonium salt is 2g / L, and the concentration of ferric ion in the iron salt is 30g / L, After the configuration is completed, mix the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt with the polymerized sodium silicate solution after pH adjustment at a volume ratio of 0.2:1, and control the temperature at 60°C for 1 hour. Then continue to add aluminum salt solution to the solution, and control the temperature at 60° C. for 2 h. After the reaction is stopped, the solution is allowed to s...

Embodiment 2

[0022] Dissolve 1 part by weight of sodium silicate in 100 parts by weight of water, stir well to make it into a polymeric sodium silicate solution, and add dilute sulfuric acid with a concentration of 0.1mol / L to the polymeric sodium silicate solution dropwise to make the pH of the solution down to 8. Configure the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt, wherein, the concentration of dicyandiamide is 30g / L, the concentration of quaternary ammonium salt is 4g / L, and the concentration of ferric ion in the iron salt is 50g / L, After the configuration is completed, mix the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt with the polymerized sodium silicate solution after pH adjustment at a volume ratio of 0.5:1, and control the temperature at 80°C for 0.5h. Then continue to add aluminum salt solution to the solution, and control the temperature at 60° C. for 2 h. After the reaction is stopped, the solution is allowed to sta...

Embodiment 3

[0024] Dissolve 1 part by weight of sodium silicate in 100 parts by weight of water, stir well to make it into a polymeric sodium silicate solution, and add dilute sulfuric acid with a concentration of 0.1mol / L to the polymeric sodium silicate solution dropwise to make the pH of the solution down to 10. Configure the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt, wherein, the concentration of dicyandiamide is 40g / L, the concentration of quaternary ammonium salt is 4g / L, and the concentration of ferric ion in the iron salt is 45g / L, After the configuration is completed, mix the mixed solution of dicyandiamide, quaternary ammonium salt and iron salt with the polymerized sodium silicate solution after pH adjustment at a volume ratio of 0.4:1, and control the temperature at 70°C for 1 hour. Then continue to add aluminum salt solution to the solution, and control the temperature at 60° C. for 4 h. After the reaction is stopped, the solution is allowed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com