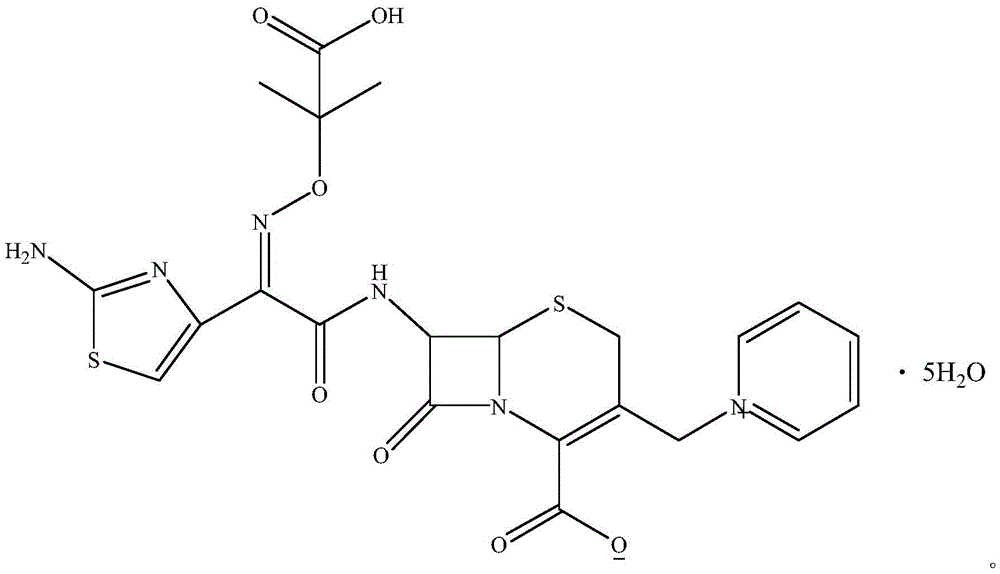

One-pot method for preparing ceftazidime

A technology for ceftazidime and aminocephalosporanic acid, which is applied in the field of medicine, can solve the problems such as prolonging the time required for the synthesis process, unsatisfactory product yield, increasing production cost and the like, and achieves avoiding the crystal growing process, reducing the workload and simplifying the treatment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

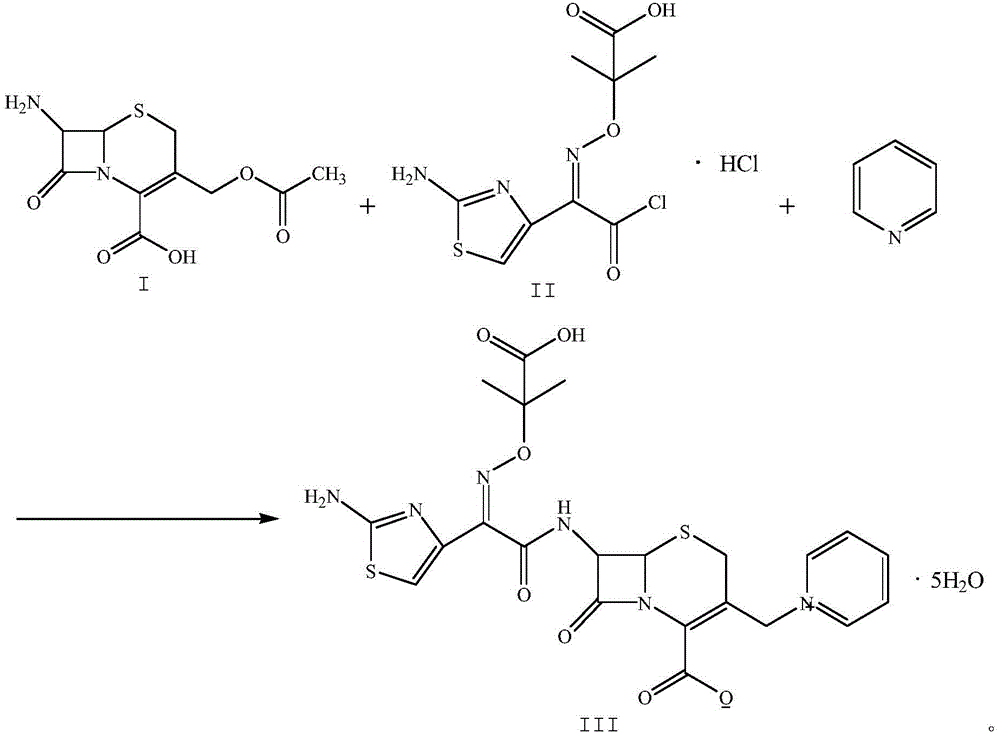

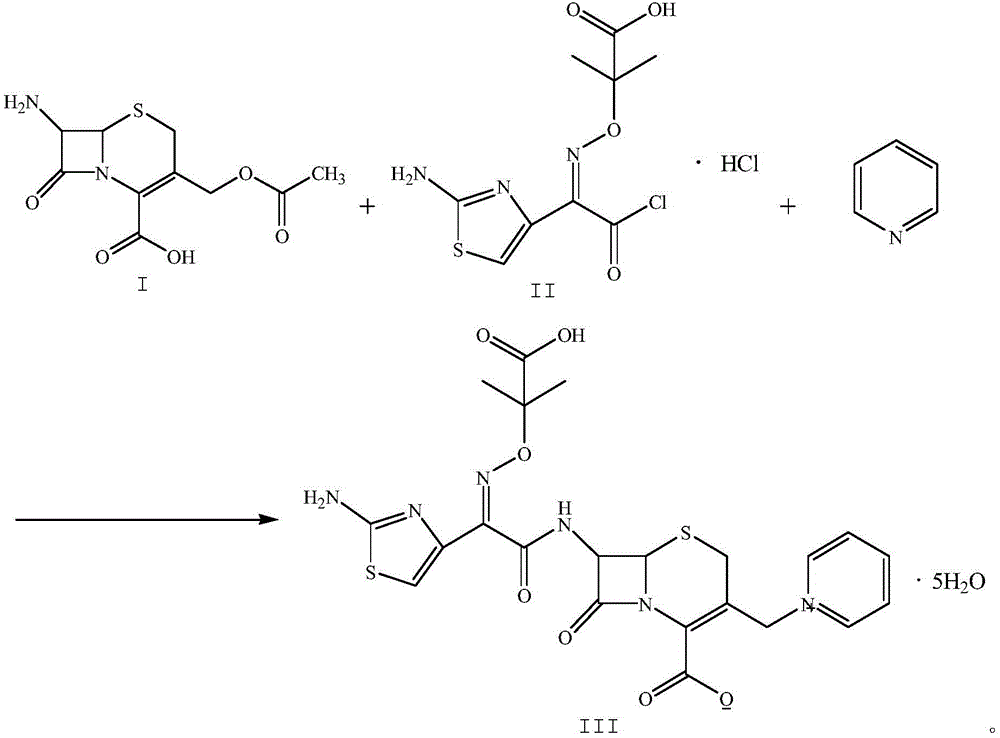

Method used

Image

Examples

Embodiment 1

[0022] The method for preparing ceftazime by one-pot method of the present invention comprises the steps of: weighing 2.72g of 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 3.28g of ceftazidime side chain acid chloride hydrochloride (compound II, MW328 , 0.01mol) and 9.48g pyridine (MW79, 0.12mol), placed in an ultrasonic reactor, -18 ° C, 750W ultrasonic vibration for 2 hours and 2 hours, adjust the pH to 4.1, add 1.632g acetone to the reaction solution, and white The solid was washed with cold water at 0°C, and vacuum-dried at 40°C for 4 hours to obtain 6.22g ceftazidime (MW636), with a yield of 97.8%, a purity of more than 99.9%, a single impurity of less than 0.01%, and acetone residue of less than 0.01%.

Embodiment 2

[0024] The method for preparing ceftazime by one-pot method of the present invention comprises the steps of: weighing 2.72g of 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 3.936g of ceftazidime side chain acid chloride hydrochloride (compound II, MW328 , 0.012mol) and 11.06g pyridine (MW79, 0.14mol), placed in an ultrasonic reactor, -15 ° C, 1000W ultrasonic vibration for 3 hours, adjust the pH to 4.2, add 2.176g acetone to the reaction solution, and precipitate a white solid, Wash with cold water at 5°C, and dry in vacuum at 50°C for 6 hours to obtain 6.24g of ceftazidime (MW636), with a yield of 98.1%, a purity of more than 99.9%, a single impurity of less than 0.01%, and acetone residue of less than 0.01%.

Embodiment 3

[0026] The method for preparing ceftazime by one-pot method of the present invention comprises the steps of: weighing 2.72g of 7-aminocephalosporanic acid (7-ACA, compound I, MW272, 0.01mol), 3.608g of ceftazidime side chain acid chloride hydrochloride (compound II, MW328 , 0.011mol) and 10.27g pyridine (MW79, 0.13mol), placed in an ultrasonic reactor, -16 ° C, 800W ultrasonic vibration for 2 hours, adjust the pH to 4.2, add 1.904g acetone to the reaction solution, and precipitate a white solid, Wash with cold water at 5°C, and dry in vacuum at 50°C for 5 hours to obtain 6.28g of ceftazidime (MW636), with a yield of 98.7%, a purity of more than 99.9%, a single impurity of less than 0.01%, and acetone residue of less than 0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com