Acrylic resin paint capable of being quickly cured

An acrylic resin, fast curing technology, applied in the direction of coating, etc., can solve the problems of easy aging, etc., achieve good weather resistance, high adhesion, and improve the effect of coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

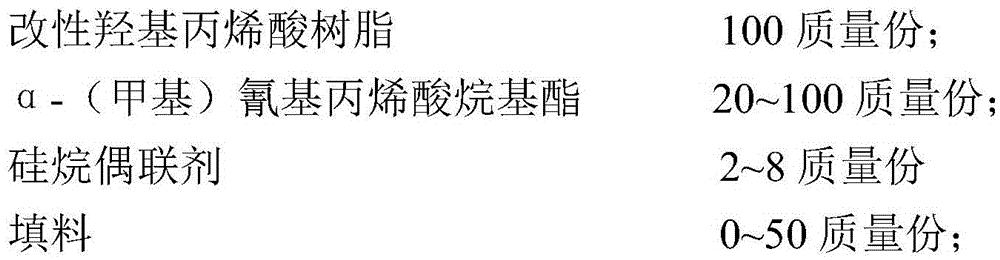

Method used

Image

Examples

example 1

[0028] Add 80 parts of xylene to the reaction kettle in parts by weight, and raise the temperature to 140°C; in the state of solvent reflux, slowly add 20 parts of methyl methacrylate, 40 parts of butyl acrylate, 15 parts of A mixture of 2-ethylhexyl acrylate, 12 parts of hydroxyethyl acrylate, 13 parts of acrylonitrile, 3 parts of di-tert-butyl peroxide, and 3 parts of mercaptothiol; after continuing the reaction for 2 hours, the addition of 1 1 part of di-tert-butyl peroxide, 20 parts of xylene, and continue the heat preservation reaction for 1 hour and then the reaction ends, and the temperature is lowered to below 70° C., discharging and filtering, to obtain the hydroxyacrylic resin a of embodiment 1 (for physical parameters, see Table I).

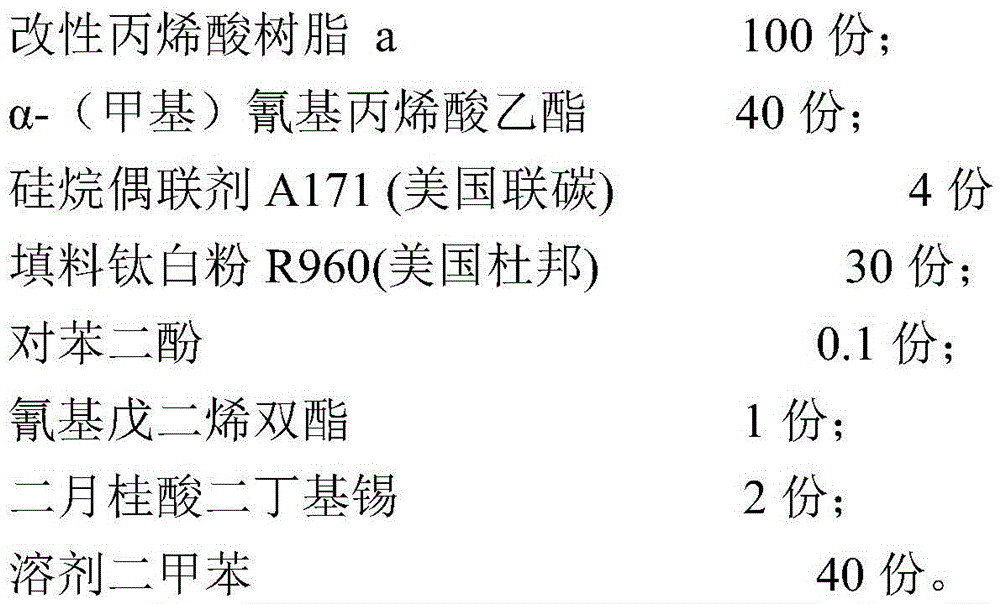

[0029] Component A:

[0030]

[0031] Component B:

[0032] Curing agent Z4470 (Bayer, Germany) 25 parts

[0033] Add 100 parts of modified acrylic resin a into a container equipped with a stirring device and start stirring, add ...

example 2

[0036] Add 75 parts of butyl acetate to the reaction kettle according to parts by weight, and heat up to 120°C; under the state of solvent reflux, slowly add 15 parts of methyl methacrylate, 35 parts of butyl acrylate, 30 parts of Parts of 2-ethylhexyl acrylate, 10 parts of 4-hydroxybutyl acrylate, 5 parts of acrylonitrile, 2.5 parts of tert-butyl peroxybenzoate, and 2 parts of mercaptothiol; after continuing to react for 2 hours, 0.5 Add the mixture of 0.5 parts of tert-butyl peroxybenzoate and 5 parts of butyl acetate within h, and continue the heat preservation reaction for 1 hour. After the reaction is completed, the temperature is lowered to below 70 ° C, and the material is discharged and filtered to obtain the product of Example 1. Hydroxy acrylic resin b (see Table 1 for physical parameters).

[0037] Component A:

[0038]

[0039]

[0040] Component B:

[0041] Curing agent N3390 (Bayer, Germany) 20 parts

[0042]Add 100 parts of modified acrylic resin b into...

example 3

[0045] Add 70 parts of methyl methacrylate, 15 parts of butyl acrylate, 25 parts of A mixture of ethyl acrylate, 5 parts of hydroxypropyl acrylate, 25 parts of acrylonitrile, 4 parts of azobisisobutyronitrile, and 2 parts of dodecanethiol; after continuing the reaction for 2 hours, 1 part of azo was added within 0.5 hours The mixture of diisobutyronitrile and 5 parts of methyl ethyl ketone, and continue the heat preservation reaction for 1 hour, then the reaction ends, the temperature is lowered to below 40° C., the material is discharged and filtered, and the hydroxyacrylic resin c of Example 1 is obtained (see Table 1 for physical parameters) .

[0046] Component A:

[0047]

[0048] Component B:

[0049] Curing agent Z4470 (Bayer, Germany) 5 parts

[0050] Add 100 parts of modified acrylic resin c into a container equipped with a stirring device and start stirring, add 8 parts of silane coupling agent A174, 50 parts of filler titanium dioxide R996, 1 part of dibutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com