Preparation process of glass fiber mesh cloth

A technology of glass fiber and preparation process, which is applied in the field of thermal insulation building materials, can solve the problems of high temperature resistance, poor alkali resistance and erosion resistance, low strength and alkali resistance retention rate, uneven surface of mesh cloth, and achieve The effect of low cost, tight organizational structure, and small coefficient of variation of gram weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

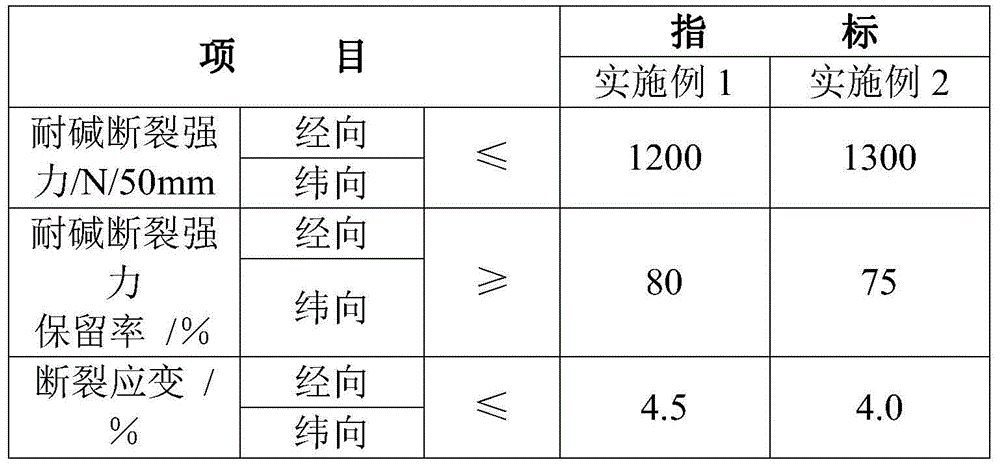

Examples

Embodiment 1

[0014] A kind of preparation technology of glass fiber grid cloth, comprises the following steps:

[0015] (1) Gray cloth weaving: several raw yarns prepared from original sodium borosilicate glass are divided into warp threads and weft threads, and the two warp threads and weft threads are cross-woven into a warp thread group, and the warp thread groups are arranged equidistantly. Sequentially it is woven into a qualified grid gray cloth, wherein the warp is the round glass fiber yarn of 265g / km; the weft is 1265g / km, the wide flat glass fiber yarn of 3mm;

[0016] (2) Acid leaching: Arrange the above-mentioned gray cloths evenly on a group of support rods, put the whole into the acid leaching tank, select hydrochloric acid with a concentration of 3.0mol / L and inject it into the acid leaching tank. Treat for 2.8 hours, and at the same time use an acid-resistant pump to circulate and stir;

[0017] (3) Water washing: the gray cloth after the above steps is washed at a tempera...

Embodiment 2

[0022] A kind of preparation technology of glass fiber grid cloth is characterized in that, comprises the following steps:

[0023] (1) Gray cloth weaving: several raw yarns prepared from original sodium borosilicate glass are divided into warp threads and weft threads, and the two warp threads and weft threads are cross-woven into a warp thread group, and the warp thread groups are arranged equidistantly. Sequentially it is woven into a qualified grid gray cloth, wherein the warp is the round glass fiber yarn of 265g / km; the weft is 1265g / km, the wide flat glass fiber yarn of 2.5mm;

[0024] (2) Acid leaching: Arrange the above-mentioned gray cloths evenly on a group of support rods, put the whole into the acid leaching tank, select hydrochloric acid with a concentration of 2.0mol / L and inject it into the acid leaching tank. Treat for 1.8 hours while circulating and stirring with an acid-resistant pump;

[0025] (3) Washing with water: the gray cloth after the above steps is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com