A high-frequency ultrasonic transducer with a curved focusing array and a preparation method thereof

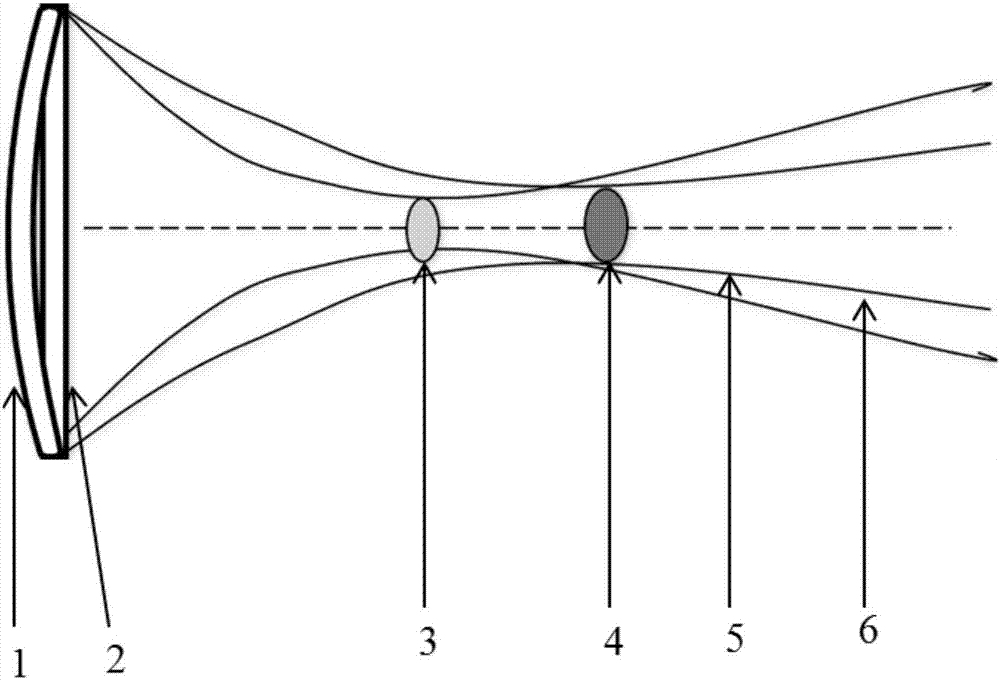

An ultrasonic transducer, curved surface technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, components of piezoelectric devices or electrostrictive devices, device components, etc. energy, low frequency, low electromechanical coupling coefficient, etc., to improve the conversion effect, improve the accuracy, and improve the piezoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the ultrasonic transducer comprises the following steps:

[0042] S1. Prepare a bottom electrode with a height of 4 μm to 20 μm on the upper surface of the curved substrate by pad printing method, the upper surface of the curved substrate is a ring with an arc of 60° to 180°;

[0043]S2. Preparing a thick film of lead magnesium niobate titanate with a height of 7 μm to 100 μm on the bottom electrode by pad printing;

[0044] S3. By controlling sputtering power, sputtering pressure and sputtering time, prepare a gold electrode with a height of 100nm to 300nm on the lead magnesium niobate titanate thick film as a top electrode by sputtering; for example, use radio frequency sputtering Sputtering, the power is 100w, the pressure is 0.5Pa, the rate is 0.3nm / s, and the sputtering time is 6min, a gold electrode with a thickness of 100nm can be obtained;

[0045] S4. Use a laser to cut the gold electrode and the lead magnesium niobate titanate thick ...

Embodiment 1

[0052] The preparation of embodiment 1 piezoelectric material

[0053] Experimental Materials:

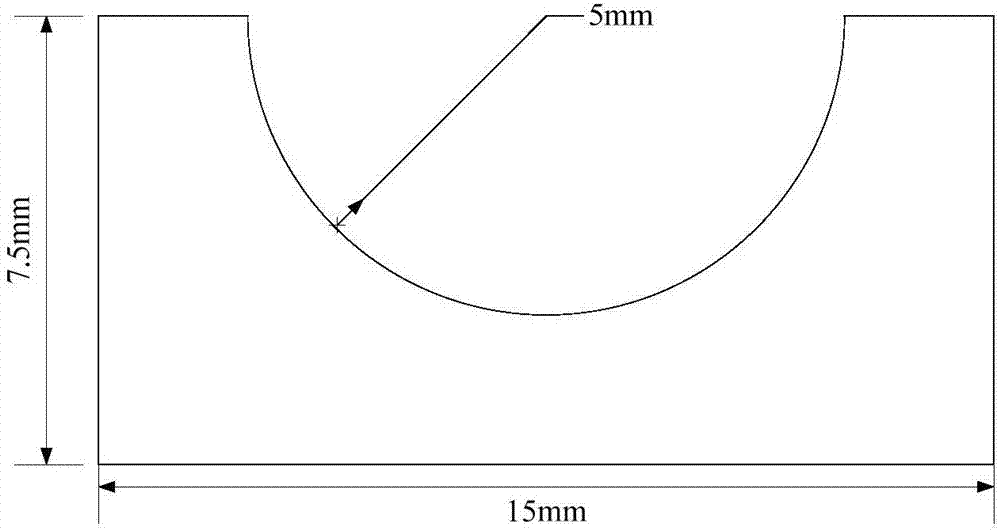

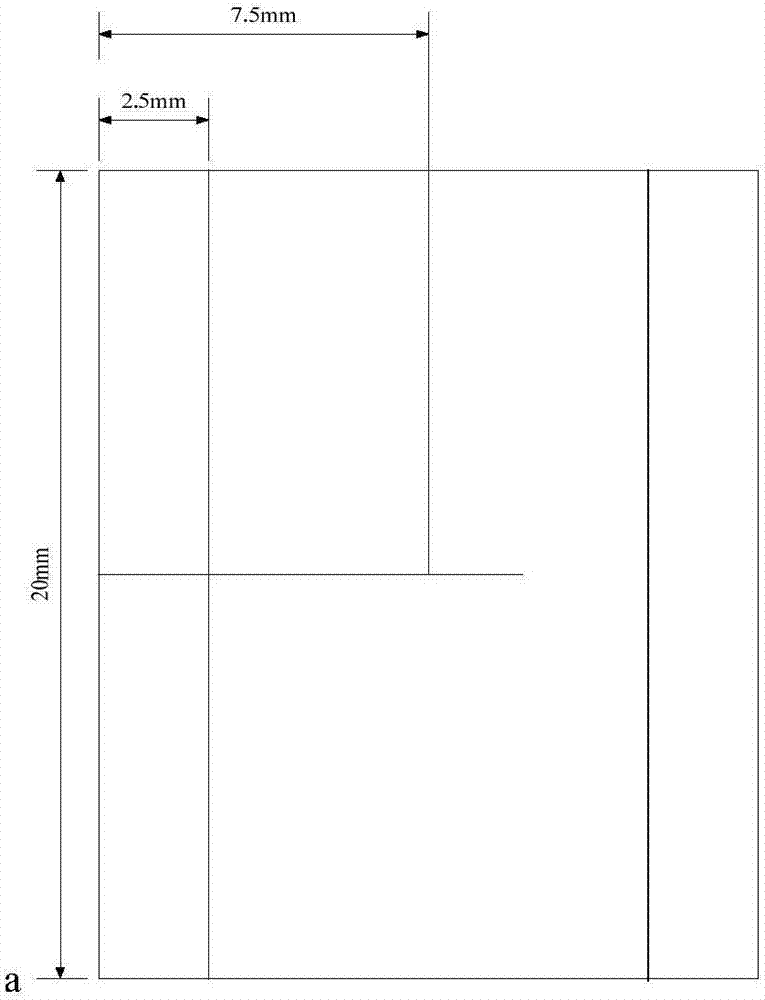

[0054] Clean PZT piezoelectric ceramic curved substrate: the custom-made PZT curved substrate has a height of 7.5mm and a width of 15mm. Its inner surface is a semi-circular ring with a diameter of 5mm. 2.5mm. Its front view and top view are as follows Figure 2a and Figure 2b shown. The PZT curved substrate was mechanically polished to remove the corroded part of the surface, rinsed with deionized water, then ultrasonically cleaned in alcohol for 10 minutes, rinsed with deionized water again, ultrasonically cleaned in acetone for 10 minutes, and then ultrasonically cleaned in alcohol for 10 minutes, Finally, rinse with deionized water and dry for later use.

[0055] Polymer solution: Mix in a beaker according to the mass ratio of polyethylene glycol 4000 (PEG-4000) and deionized water at 3:20. After mixing, stir on a magnetic stirrer for 20 minutes to form a 15% polymer solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com