Taglam plant milk and making process thereof

A preparation process and a leaf-eating technology, applied in the field of Nutritious Beverages, can solve the problems of incomplete nutrition, incomplete functions, market influence, etc., and achieve the effects of rich nutritional value, high functional value and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

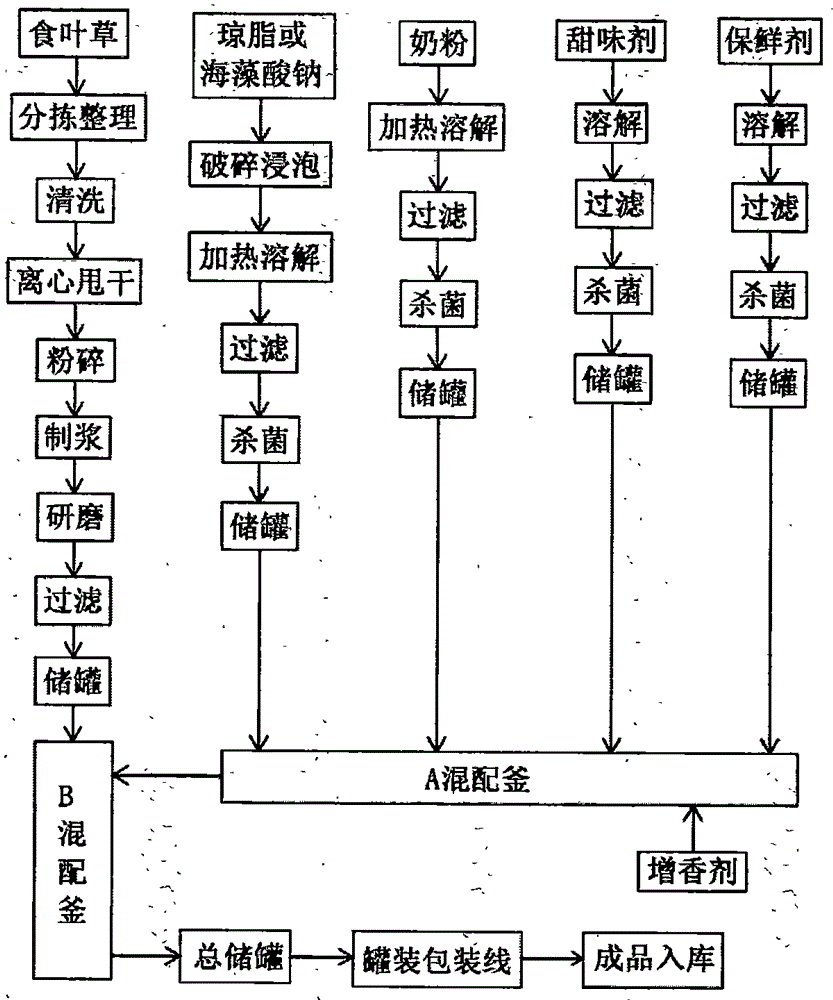

Image

Examples

Embodiment 1

[0034] 1.1 Formula composition

[0035] Element

Dosage (weight)

Lemongrass Serum

280

0.09

sweet baby

0.2

0.4

0.08

water

719.23

[0036] 1.2 steps

[0037] Step1: Preparation of the leaf-eating grass slurry: After sorting and sorting the leaf-eating grass, it is cleaned in turn, centrifuged and dried to remove floating water, crushed with a pulverizer to 60 mesh, removed with a slurry filter, and used with a slurry colloid mill Grinding to more than 180 mesh, and filtering with a 180 mesh slurry filter sterilizer to obtain leaf-eating grass slurry;

[0038] Step2: Preparation of agar solution: crush the agar to above 80 mesh, soak in warm water for 20-30 minutes, heat to 95°C to dissolve, keep the state for 15-20 minutes when the temperature is lowered to 90°C, and filter when the temperature is lowered to 50-60°C , sterilization, and storage tank to o...

Embodiment 2

[0043] 2.1 Formula composition

[0044] Element

Dosage (weight)

Lemongrass Serum

400

sodium alginate

0.72

0.2

0.3

0.10

water

598.68

[0045] 2.2 steps

[0046] Step1: Preparation of the leaf-eating grass slurry: After sorting and sorting the leaf-eating grass, it is cleaned in turn, centrifuged and dried to remove floating water, crushed with a pulverizer to 60 mesh, removed with a slurry filter, and used with a slurry colloid mill Grinding to more than 180 mesh, and filtering with a 180 mesh slurry filter sterilizer to obtain leaf-eating grass slurry;

[0047]Step2: Preparation of sodium alginate solution: crush sodium alginate to more than 80 mesh, soak in warm water for 20-30 minutes, heat to 95°C to dissolve, cool to 90°C and keep the state for 15-20 minutes, cool to 50- At 60°C, filter, sterilize, and store in a tank to obtain a sodium alginate...

Embodiment 3

[0052] 3.1 Formula composition

[0053] Element

Dosage (weight)

Lemongrass Serum

100

agar

0.5

3

0.5

0.12

milk powder

55

water

840.88

[0054] 3.2 steps

[0055] Step1: Preparation of the leaf-eating grass slurry: After sorting and sorting the leaf-eating grass, it is cleaned in turn, centrifuged and dried to remove floating water, crushed with a pulverizer to 60 mesh, removed with a slurry filter, and used with a slurry colloid mill Grinding to more than 180 mesh, and filtering with a 180 mesh slurry filter sterilizer to obtain leaf-eating grass slurry;

[0056] Step2: Preparation of agar solution: crush the agar to above 80 mesh, soak in warm water for 20-30 minutes, heat to 95°C to dissolve, keep the state for 15-20 minutes when the temperature is lowered to 90°C, and filter when the temperature is lowered to 50-60°C , sterilization, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com