Preparing method of particle caesium removing inorganic ion adsorbent and product and application

An inorganic ion and adsorbent technology, which is applied in the field of material preparation and radioactive wastewater treatment, can solve the problems of reduced adsorbent performance, large particle size of silica gel balls, and difficulty in complete ferrocyanide, achieving stable structure and high adsorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

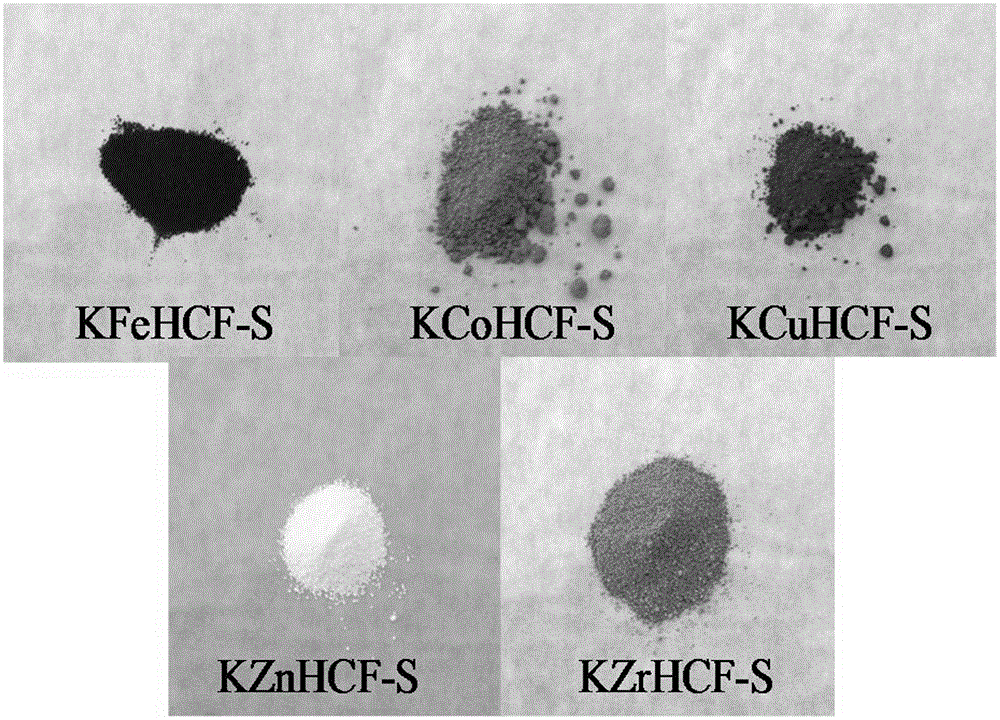

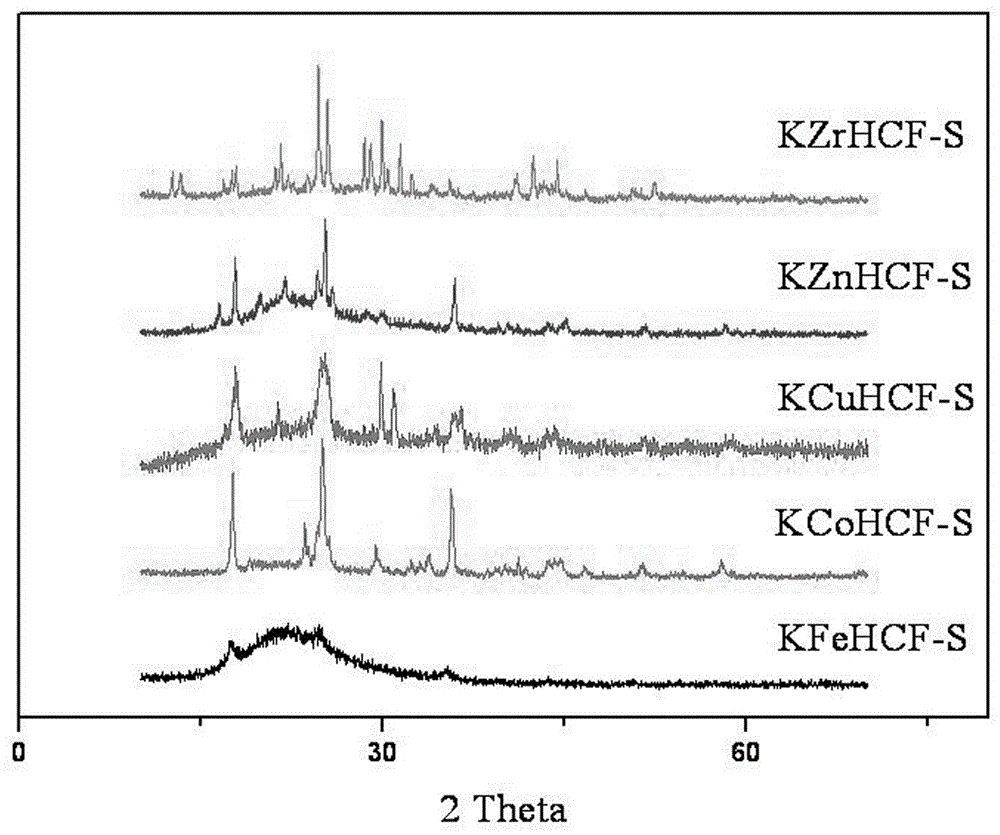

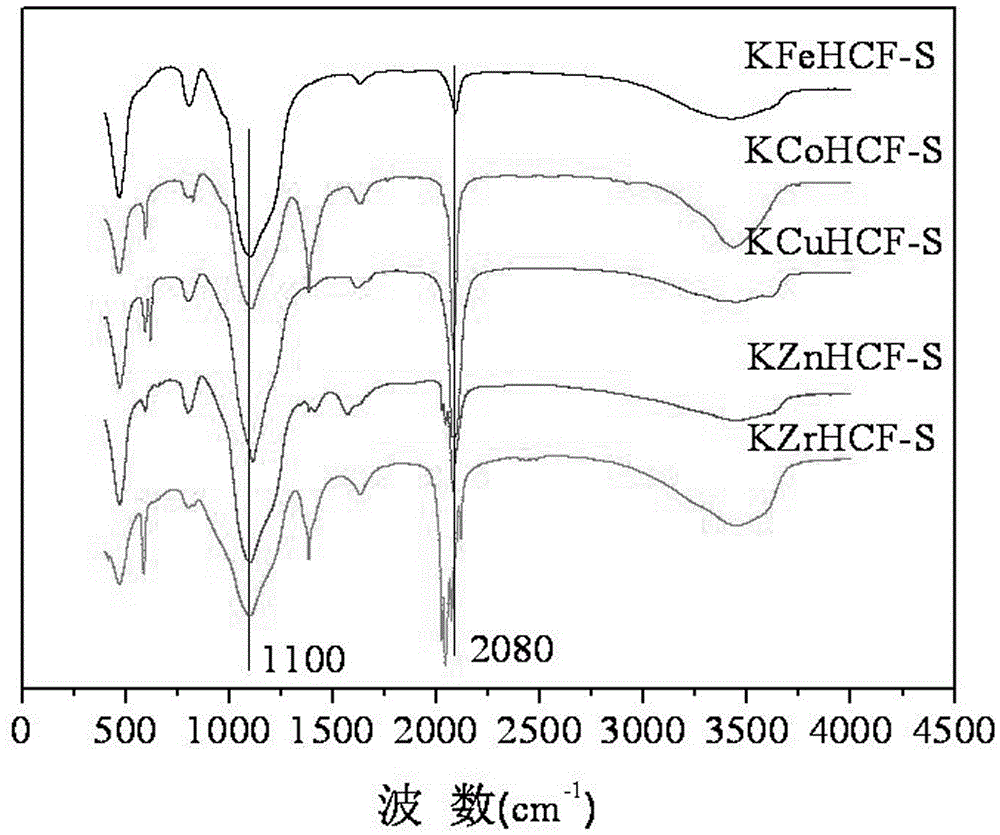

[0057] Embodiment 1: the laboratory preparation of five kinds of silica gel-loaded adsorbents

[0058] Two-step impregnation method to prepare silica-supported adsorbent:

[0059] 1) Add 4L of deionized water to five 10L beakers respectively, add: A—630g of Co(NO 3 ) 2 ·6H 2 O; B—790g of CuSO 4 ·5H 2 O; C—180g of (CH 3 COO) 2 Zn·2H 2 O; D—1020g of ZrO(NO 3 ) 2 ; E—430g of FeCl 3 ·6H 2 O. Heat and stir until completely dissolved, then pour the five solutions into five enamel trays each containing 1kg of silica gel particles, the solution is basically immersed in all the silica gel, and stand for 3 hours, stirring often during the process to make the particles impregnated evenly. Then put the 5 trays in a constant temperature oven and dry them at 120°C for 10 hours, then take them out and cool down naturally to obtain silica gel intermediates impregnated with different ions.

[0060] 2) Add 5L of deionized water to each of the five 10L beakers of A, B, C, D, and E, ...

Embodiment 2

[0066] Example 2: Trial production of a single batch of 500kg KCuHCF-S

[0067] Add 500L of water to a 1 ton reaction box, and add 395kg of CuSO 4 ·5H 2 O, heated to 80°C with continuous stirring to dissolve completely. Then add 500kg of silica gel carrier, impregnate at 80°C for 12 hours, and stir frequently during the process to make the adsorption process uniform. Afterwards, the material was filtered, placed in a tray, and dried in an electric blast drying room at 120°C for 24 hours. The filtrate was collected and the water uptake of the first maceration was determined by volume. Pour the filtrate back into the reaction box, and add water in it, so that the volume of the solution is equal to the amount of water absorbed for the first time. Put the dried material into the reaction box again, repeat the first impregnation process and operating conditions until the solution is basically absorbed. Place the material in a tray again, and dry it in an electric blast drying ...

Embodiment 3

[0070] Example 3: Trial production of 500kg KZnHCF-S in a single batch

[0071] Add 500L water in 1 ton of reaction box, add 92kg (CH 3 COO) 2 Zn·2H 2 O, heated to 40°C with continuous stirring to dissolve completely. Then add 500kg of silica gel carrier, impregnate at 40°C for 12 hours, and stir frequently during the process to make the adsorption process uniform. Afterwards, the material was filtered, placed in a tray, and dried in an electric blast drying room at 120°C for 24 hours. The filtrate was collected and the water uptake of the first maceration was determined by volume loss. Pour the filtrate back into the reaction box, add water to make the volume of the solution equal to the first water absorption. Put the dried material into the reaction box again, repeat the first impregnation process and operating conditions until the solution is basically absorbed. Place the material in the tray again, and dry it in an electric blast drying room at 120°C for 24 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com