Beneficiation method for rubidium-containing feldspar quarry

A beneficiation method and rubidium feldspar technology are applied in the field of beneficiation of rubidium-containing feldspar ore, which can solve the problems of reducing the amount of material input, reducing the cost of chemical extraction of rubidium, and achieving improved recovery rate, collection capacity and strong selectivity. The effect of high comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

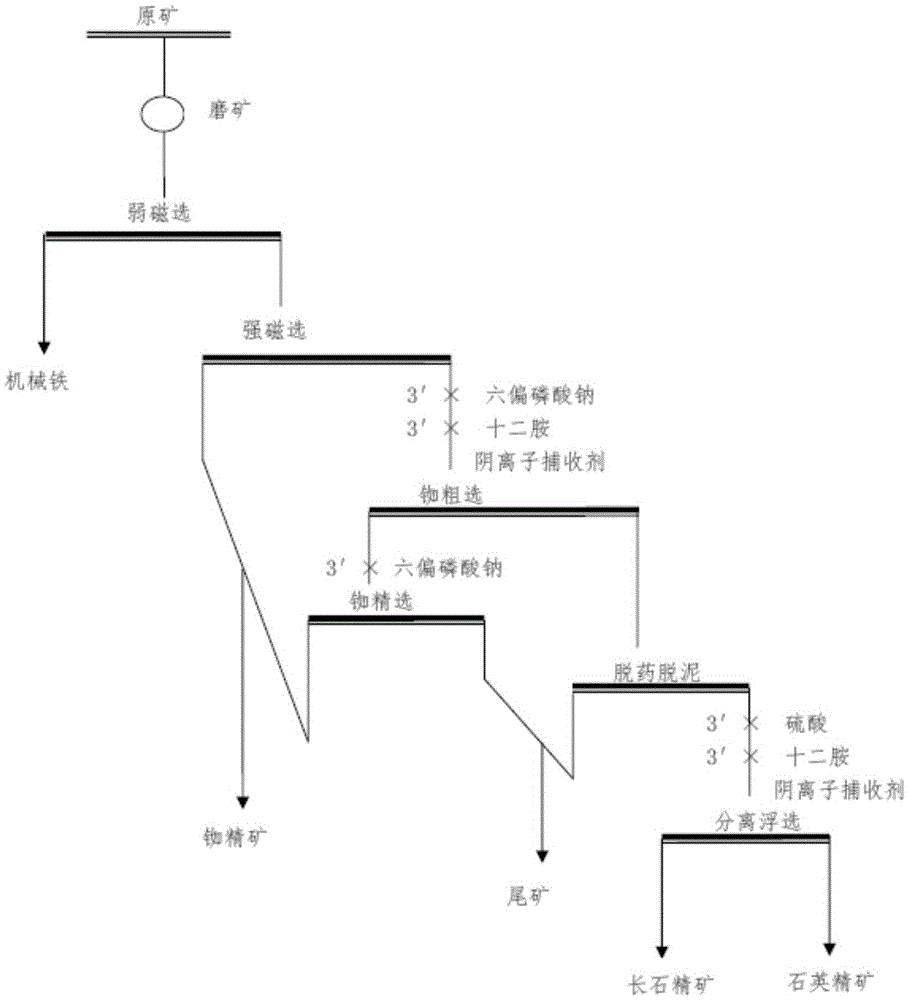

Image

Examples

Embodiment 1

[0037] A rubidium-containing feldspar mine, the main minerals in the ore are albite, potassium feldspar (tianhe stone), quartz, and the secondary mineral is iron lepidolite. Rubidium mainly occurs in iron lepidolite and potassium feldspar (tianhe stone) , the raw ore contains Rb 2 O0.13%, containing K 2 O3.82%, containing Na 2 O5.14%, containing Fe 2 o 3 0.57%.

[0038] Use mineral processing method of the present invention to carry out mineral processing to above-mentioned ore, concrete steps are as follows:

[0039] 1) Take -2mm raw ore 400g to grind ore, and the grinding fineness is -0.074mm to account for 66%, and the mechanical iron with a yield of 0.8% is removed first by a weak magnetic machine at a field strength of 79.6KA / m to obtain a magnetically separated coarse pulp;

[0040] 2) The magnetically separated rough pulp is subjected to magnetic separation by a slon pulsating high-gradient strong magnetic machine with a field strength of 955.4KA / m to obtain a yie...

Embodiment 2

[0049] A rubidium-containing feldspar mine, the main minerals in the ore are albite, potassium feldspar (tianhe stone), quartz, and the secondary mineral is iron lepidolite. Rubidium mainly occurs in iron lepidolite and potassium feldspar (tianhe stone) , the raw ore contains Rb 2 O0.12%, containing K 2 O3.57%, containing Na 2 O5.30%, containing Fe 2 o 3 0.63%.

[0050] Use mineral processing method of the present invention to carry out mineral processing to above-mentioned ore, concrete steps are as follows:

[0051] 1) Take 400g of -2mm raw ore to grind ore, and the grinding fineness is -0.074mm, which accounts for 75%, and the mechanical iron with a yield of 0.92% is removed first by using a weak magnetic machine at a field strength of 119.4KA / m, to obtain a magnetically separated coarse pulp;

[0052] 2) The magnetically separated rough pulp is subjected to magnetic separation through a slon pulsating high-gradient strong magnetic machine with a field strength of 796...

Embodiment 3

[0062] A rubidium-containing feldspar mine, the main minerals in the ore are albite, potassium feldspar (tianhe stone), quartz, and the secondary mineral is iron lepidolite. Rubidium mainly occurs in iron lepidolite and potassium feldspar (tianhe stone) , the raw ore contains Rb 2 O0.12%, containing K 2 O3.85%, containing Na 2 O5.18%, containing Fe 2 o 3 0.71%.

[0063] Use mineral processing method of the present invention to carry out mineral processing to above-mentioned ore, concrete steps are as follows:

[0064] 1) Take 400g of -2mm raw ore for grinding, and the grinding fineness is -0.074mm, accounting for 50%;

[0065] 2) The raw ore after grinding is magnetically separated using a slon pulsating high-gradient strong magnetic machine with a field strength of 955.4KA / m to obtain a yield of 7.38%, a rubidium content of 0.49% and a rubidium-containing magnetic substance with a feed concentration of 25%;

[0066] 3) For non-magnetic materials, use a 1-liter flotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com