Preparation method of super thermite with core-shell structure

A technology of super thermite and core-shell structure, applied in metal processing equipment, transportation and packaging, etc., can solve problems such as inability to meet the effective contact between metal and oxidant molecular scale, difficult to meet application requirements, complex process equipment, etc., to avoid The mass transfer distance is too large to avoid uneven distribution and the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The preparation of embodiment 1nAlDOPA-Cu

[0019] (1) Disperse 5g of nano-aluminum powder in 100mL of distilled water in an ice bath, add 2g of levodopa (DOPA), adjust the pH value in the range of 8.5 to 12 and stir for 1 to 2 hours; weigh 4.84g (0.02mol) Copper nitrate was dissolved in the above suspension, stirred and mixed evenly;

[0020] (2) stirring and reacting in ice bath for 4h, then standing;

[0021] (3) The precipitate was washed with deionized water several times and dried to obtain a dark gray product.

Embodiment 2

[0022] The preparation of embodiment 2nAlDOPA-Fe

[0023] (1) Weigh 5g of nano-aluminum powder, disperse it in 100mL of distilled water under ice bath conditions, add 2g of levodopa (DOPA), adjust the pH value in the range of 8.5-12 and disperse and stir for 1-2h; weigh 8.08g (0.02mol) ferric nitrate is dissolved in above-mentioned suspension liquid, stirs and mixes;

[0024] (2) stirring and reacting in ice bath for 3h, then standing;

[0025] (3) The precipitate was washed with deionized water several times and dried to obtain a dark gray product.

Embodiment 3

[0026] The preparation of embodiment 3nAlDOPA-Mg

[0027] (1) Weigh 5g of nano-aluminum powder, disperse it in 100mL of distilled water under ice bath conditions, add 2g of levodopa (DOPA), adjust the pH value in the range of 8.5-12 and disperse and stir for 1-2h; weigh 5.12g (0.02mol) magnesium nitrate is dissolved in above-mentioned suspension liquid, stirs and mixes;

[0028] (2) stirring and reacting in ice bath for 4h, then standing;

[0029] (3) The precipitate was washed with deionized water several times and dried to obtain a dark gray product.

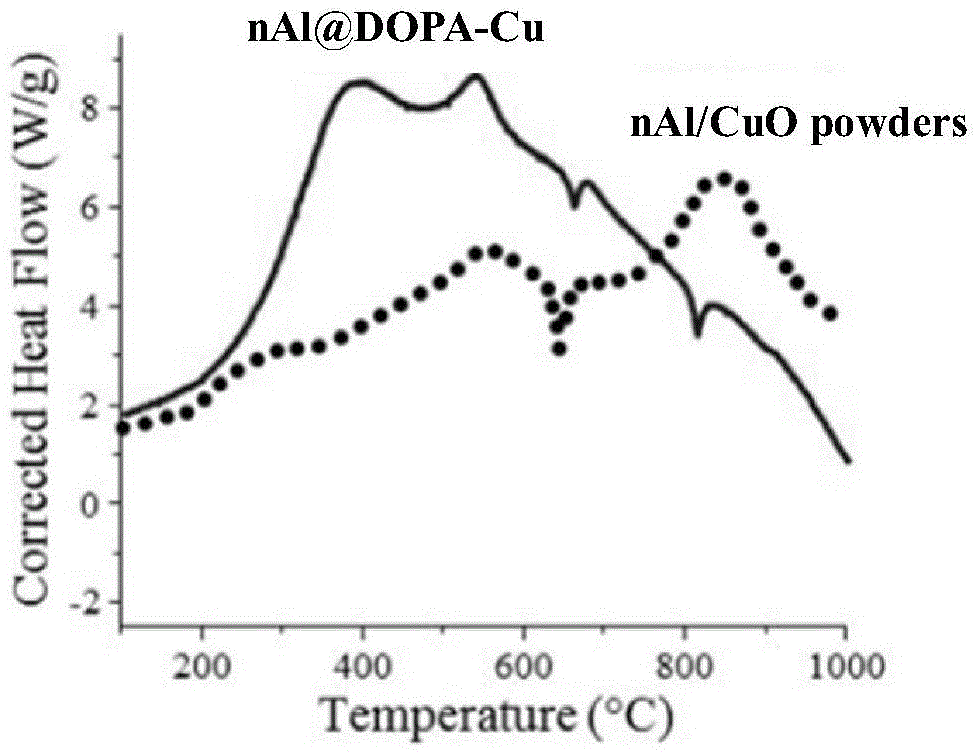

[0030] Characterization and Performance Test of nAlDOPA-M Super Thermite

[0031] 1. Structural characterization

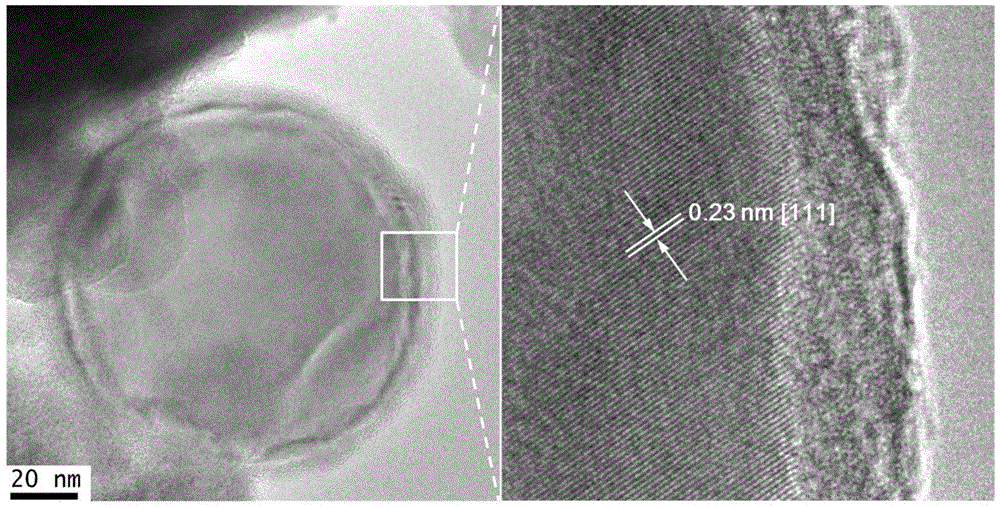

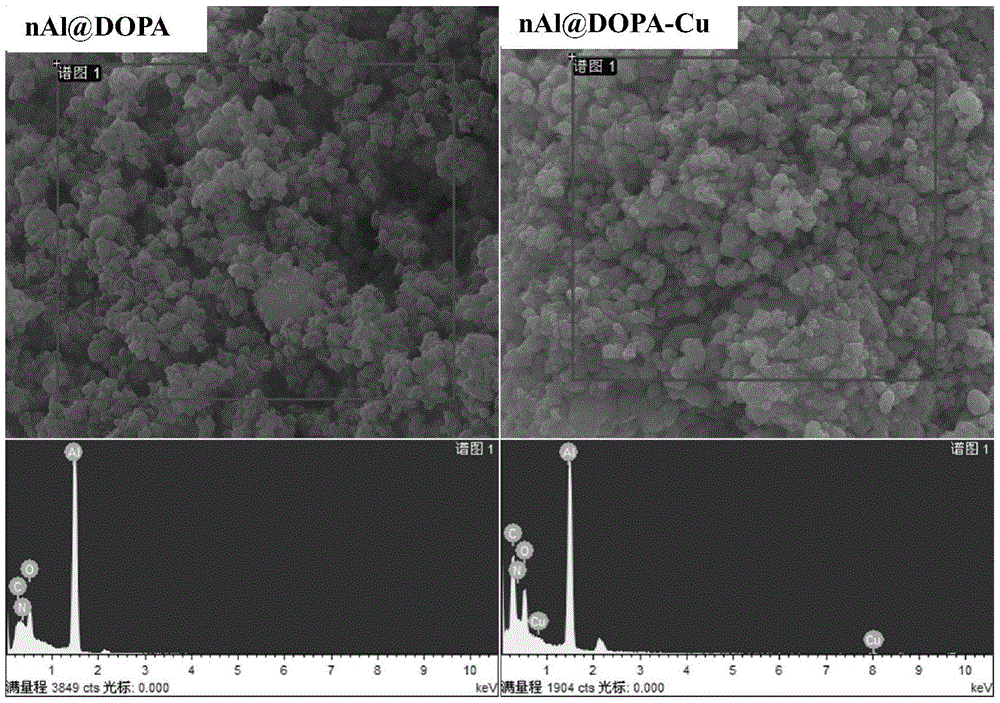

[0032] Taking the nAlDOPA-Cu sample as an example, figure 1 is a transmission electron micrograph of the sample. It can be clearly seen from the figure that the prepared sample is a complete core-shell structure. The particle size is about 100nm, and the thickness of the shell layer is about 10nm. Since no o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com