Preparation method of concrete erosion medium inhibiting material

A concrete and medium technology, applied in the field of concrete, can solve the problems of concrete cracking, inability to meet the waterproof and anti-seepage requirements of construction projects, and the limited waterproof effect of waterproofing agents, and achieve good waterproof, excellent plugging effect, and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

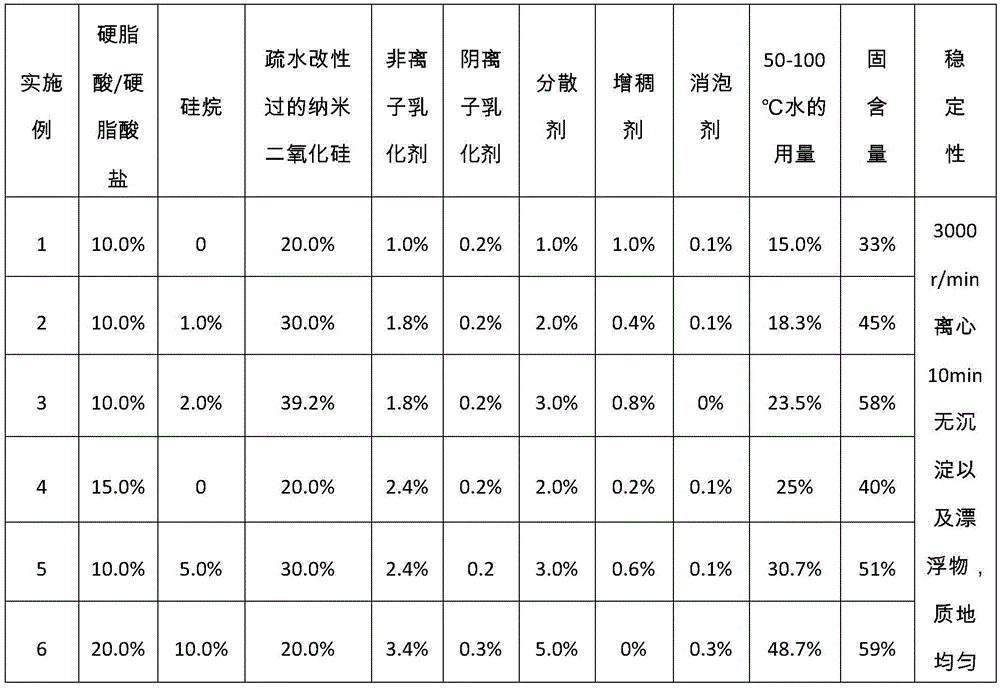

Embodiment 1

[0037] Mix 200g of nano-silica and 10g of methyltrimethoxysilane evenly, continue to stir and heat to 100°C for 90 minutes to obtain hydrophobically modified nano-silica;

[0038] Heat 50g of stearic acid to 65°C to melt, add 5g of nonionic emulsifier Pingping plus 20, 1g of sodium dodecyl sulfate SDS, 50g of water at 65°C, and shear at 1500r / min for 10min, then Quickly add 284g of water at 25°C and stir for 10min, continue to add 5g of sodium polyacrylate dispersant, 100g of hydrophobically modified nano-silica, 5g of hydroxyethyl cellulose thickener, and 0.5g of mineral oil defoamer to obtain Concrete erosion media suppression material. Its solid content was tested to be 33%.

Embodiment 2

[0040] Mix 200g of nano-silica and 10g of methyltriethoxysilane evenly, continue to stir and heat to 100°C for 90 minutes to obtain hydrophobically modified nano-silica;

[0041]Heat 50g of stearic acid to 75°C to melt, add a water dispersion consisting of 5g of methyltriethoxysilane, 9g of nonionic emulsifier Tween 80, 1g of sodium ethoxylated alkyl sulfate, and 50g of water at 75°C , 2000r / min high-speed shearing for 20min, then quickly add 223g of 25°C water and stir for 10min, continue to add 10g of sodium polyacrylate dispersant, 150g of hydrophobically modified nano-silica, 2g of hydroxyethyl cellulose thickener, 0.5g of mineral oil defoamer, that is, to obtain concrete corrosion medium suppression material. Its solid content was tested to be 45%.

Embodiment 3

[0043] Mix 200g of nano-silica and 10g of propyltriethoxysilane evenly, continue to stir and heat to 100°C for 90 minutes to obtain hydrophobically modified nano-silica;

[0044] Heat 50g of stearic acid to 85°C to melt, add 10g of propyltriethoxysilane, 9g of nonionic emulsifier Tween 80, 1g of isomeric alcohol polyoxyethylene ether sodium sulfate, and 50g of water at 85°C for dispersion liquid, 2000r / min high-speed shear for 20min, then quickly add 162g of 15°C water and stir for 20min, continue to add 15g of sodium polyacrylate dispersant, 200g of hydrophobically modified nano-silica, 4g of hydroxyethyl cellulose thickener , that is, the medium-inhibiting material for concrete erosion is obtained. Its solid content was tested to be 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| gas content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com