Method for preparing baking-free ecological bricks from chemical and residual sludge as well as prepared product

A technology of surplus sludge and ecological bricks, which is applied in the direction of ceramic products, other household utensils, household utensils, etc., can solve the problems of complex composition and high moisture content of chemical surplus sludge, and achieve large processing capacity, high strength and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

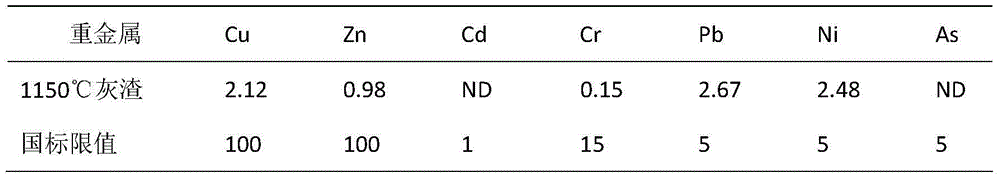

[0026] The remaining chemical sludge was dried at 120°C for 6 hours to obtain dried sludge, and the dried sludge was incinerated with oxygen at 1150°C for 1 hour, and passed through a 100-mesh sieve after cooling to obtain ash. According to the "Solid Waste Leaching Toxicity Leaching Method Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), the leaching concentration of heavy metals in the chemical residue sludge incineration ash was determined. The test results are shown in Table 1.

[0027] Table 1 Concentration of heavy metals leached from chemical residual sludge incineration ash (mg / l)

[0028]

[0029] Heat the kaolin at 800°C, calcinate for 2 hours, and cool to obtain metakaolin.

[0030] Take 60g of ash and 40g of metakaolin and stir evenly; add 8.8g of sodium hydroxide, 8.8g of sodium silicate and 8g of water, stir in a mixer, and mix thoroughly to obtain a slurry; squeeze the mixed slurry into a 16mm× 16mm×20mm rectangular parallelepiped test piece, and sent to th...

Embodiment 2

[0032] Take the remaining chemical sludge and dry it at 120°C for 6 hours to obtain dried sludge. The dried sludge is incinerated with oxygen at 1150°C for 1 hour. After cooling, it passes through a 100-mesh sieve to obtain ash; keep kaolin at 800°C for 2 hours. , cooled to obtain metakaolin. Take 60g of ash and 40g of metakaolin and stir evenly; add 7.2g of sodium hydroxide, 7.2g of sodium silicate and 10g of water, stir in a mixer, and mix thoroughly to obtain a slurry; squeeze the mixed slurry into a 16mm× 16mm×20mm rectangular parallelepiped test piece, and sent to the drying oven, 80 ℃ curing 23h; take out the sample demoulding, continue curing 7d at 80 ℃, to get chemical residue sludge-based non-burning ecological brick. After testing, the compressive strength is 14.78MPa.

Embodiment 3

[0034] Take the remaining chemical sludge and dry it at 120°C for 6 hours to obtain dried sludge. The dried sludge is incinerated with oxygen at 1150°C for 1 hour. After cooling, it passes through a 100-mesh sieve to obtain ash; keep kaolin at 800°C for 2 hours. , cooled to obtain metakaolin. Take 60g of ash and 40g of metakaolin and stir evenly; add 9.6g of sodium hydroxide, 9.6g of sodium silicate and 10g of water, stir in a mixer, and mix thoroughly to obtain a slurry; squeeze the mixed slurry into a 16mm× 16mm×20mm rectangular parallelepiped test pieces, and sent to the drying oven, 60 ℃ curing 23h; take out the sample demoulding, at 60 ℃ to continue curing 7d, that is, chemical residue sludge-based non-fired ecological bricks. After testing, the compressive strength is 13.98MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com