Sodium alginate-agar dual-network high-strength natural hydrogel material, and preparation method thereof

A sodium alginate and gel material technology, applied in the field of polymer materials, can solve the problems of chemical cross-linking that cannot be rebuilt, and achieve great application value, easy operation, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

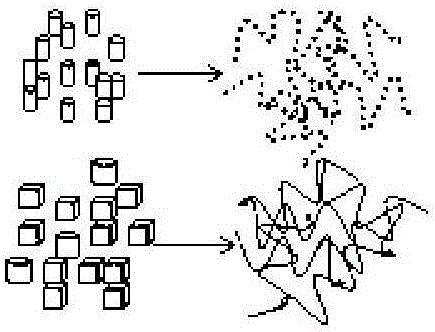

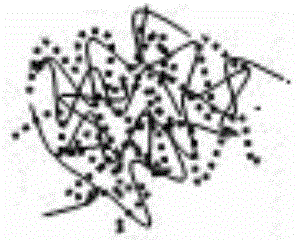

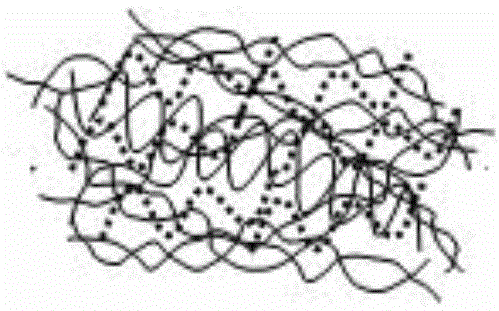

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Add 0.88g of sodium alginate (SA) powder into 30mL of deionized water, stir in a 65°C water bath for 30 minutes to fully dissolve it, and obtain a sodium alginate (SA) solution with a mass fraction of 2.85%; 4.4g of agar ( Agar) powder was added into 80mL of deionized water, stirred in a 95°C water bath for 30 minutes to fully dissolve it in deionized water to obtain an agar (Agar) solution with a mass fraction of 5.21%;

[0039] 2) Add the agar (Agar) solution in step 1) into the sodium alginate (SA) solution, and stir in a water bath at 65° C. for 15 minutes to obtain a mixed solution;

[0040] The mass fraction of agar (Agar) in the mixed solution is 3.82%, and the mass ratio of sodium alginate (SA) to agar (Agar) in the mixed solution is 1.0:5.0;

[0041] 3) Use a disposable syringe to extract 5 mL of the mixed solution in step 2), and centrifuge to remove air bubbles to obtain a transparent and uniform mixed solution;

[0042] 4) Cool the mixed solution that ha...

Embodiment 2

[0045] Embodiment 2, with embodiment 1, difference is,

[0046] 1) Add 5.80 g of agar (Agar) powder into 80 mL of deionized water, stir in a water bath at 95° C. for 30 minutes, fully dissolve it in deionized water, and obtain an agar (Agar) solution with a mass fraction of 6.76%;

[0047] 2) Add the agar (Agar) solution in step 1) into the sodium alginate (SA) solution, and stir in a water bath at 65° C. for 15 minutes to obtain a mixed solution;

[0048] The mass fraction of agar (Agar) in the mixed solution is 4.97%, and the mass ratio of sodium alginate (SA) to agar (Agar) in the mixed solution is 1.0:6.6;

[0049] 5) Cut the disposable syringe, take out the preformed gel from the syringe tube, and dissolve the preformed gel in 30mL0.75mol / LCaCl 2 Soaked in aqueous solution for 5 hours, Ca 2+ Sodium alginate (SA) is cross-linked into the second network by diffusing into the preformed hydrogel, and sodium alginate agar fully physically cross-linked high-strength double-ne...

Embodiment 3

[0051] Embodiment 3, with embodiment 1, difference is,

[0052] 1) Add 8.80 g of agar (Agar) powder into 80 mL of deionized water, stir in a water bath at 95°C for 30 minutes to fully dissolve it in deionized water, and obtain an agar (Agar) solution with a mass fraction of 9.91%;

[0053] 2) Add the agar (Agar) solution in step 1) into the sodium alginate (SA) solution, and stir in a water bath at 65° C. for 15 minutes to obtain a mixed solution;

[0054] The mass fraction of agar (Agar) in the mixed solution is 7.35%, and the mass ratio of sodium alginate (SA) to agar (Agar) in the mixed solution is 1.0:10.0;

[0055] 5) Cut the disposable syringe, take out the preformed gel from the syringe tube, and dissolve the preformed gel in 30mL0.5mol / LCaCl 2 Soaked in aqueous solution for 6 hours, Ca 2+ Sodium alginate (SA) is cross-linked into the second network by diffusing into the preformed hydrogel, and sodium alginate agar fully physically cross-linked high-strength double-ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com