Antistatic agent for biaxially oriented polypropylene films in extremely-cold areas and preparation method of antistatic agent

A polypropylene film and antistatic agent technology, applied in the field of biaxially oriented polypropylene film processing additives, can solve the problems of restricting the development of BOPP, the production capacity is less than 500,000 tons, restricting the development of the company, etc., and achieves easy popularization and antistatic effect. Obviously, the effect of solving the technical problems of antistatic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

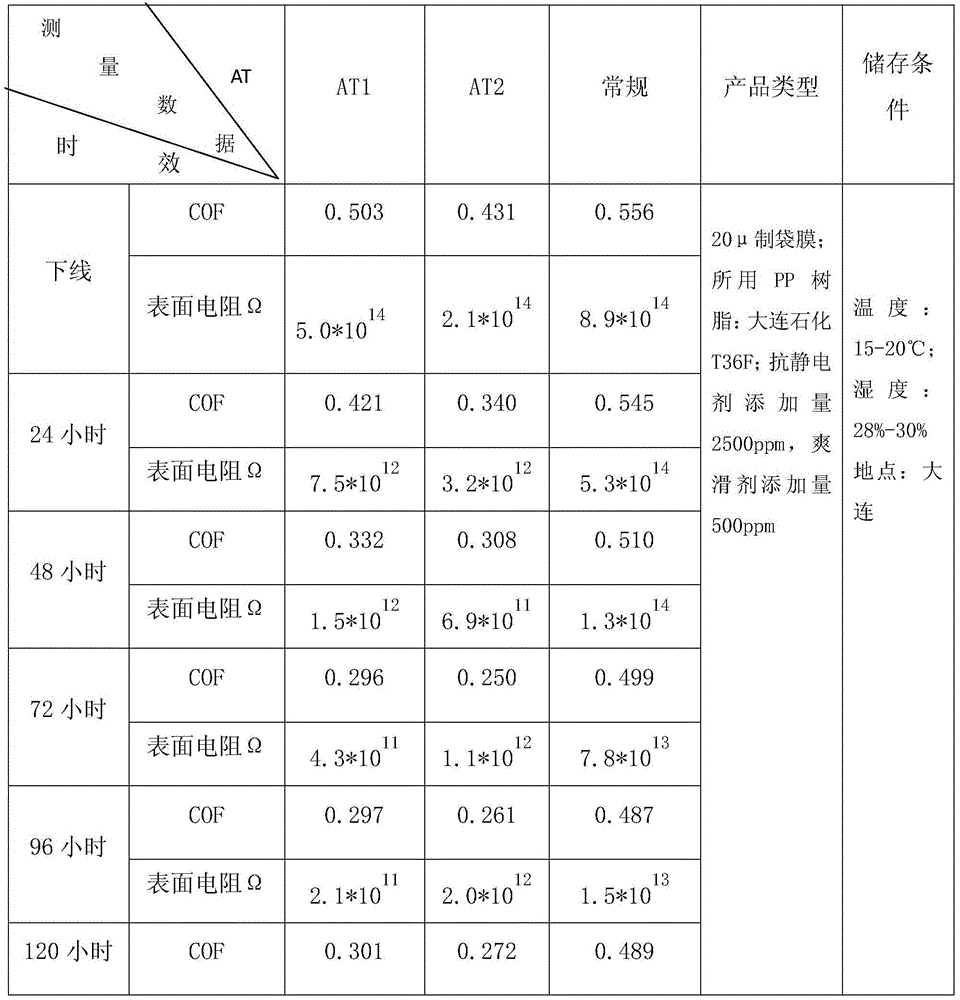

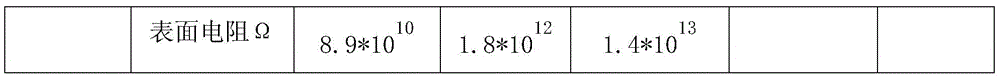

Image

Examples

Embodiment 1

[0025] Modifier preparation

[0026] 75 kilograms of octadecylamine, 8.3 kilograms of N, N-bis (hydroxyethyl) cocamide, 16.7 kilograms of boric acid alkyl alcohol amine esters are added to the high mixer and mixed into the reaction kettle to feed 12.5 kilograms of ethylene oxide Addition reactions give modifiers.

Embodiment 2

[0028] Preparation of antistatic agent AT1

[0029] (1) The weight percent is respectively 12%, 8%, 0.3%, 79.7% modifier, monoglyceride, tris (2,4-di-tert-butyl) phenyl phosphite, and polypropylene are mixed evenly to obtain a mixture material;

[0030] (2) Add the mixture into THJ-high speed and high torque co-rotating parallel twin-screw mixing extruder to melt and extrude to make antistatic masterbatch. Extrusion temperature is 210°C, pressure is 6Mpa, speed is 500rpm, and screw diameter is 75mm. , aspect ratio 40:1;

[0031] (3) cooling and drying the antistatic masterbatch made in step (2), pelletizing;

[0032] (4) The antistatic masterbatch after pelletizing was circulated, dried, mixed and uniformly packed into bags to obtain the antistatic agent AT1.

Embodiment 3

[0034] Preparation of antistatic agent AT2

[0035] (1) Mix modifiers, monoglycerides, tris(2,4-di-tert-butyl)phenyl phosphite and polypropylene with weight percentages of 8%, 12%, 0.3%, and 79.7% respectively to obtain a mixed mixture material;

[0036] (2) Add the mixture into THJ-high speed and high torque co-rotating parallel twin-screw mixing extruder to melt and extrude to make antistatic masterbatch. Extrusion temperature is 210°C, pressure is 6Mpa, speed is 500rpm, and screw diameter is 75mm. , aspect ratio 40:1;

[0037] (3) cooling and drying the antistatic masterbatch made in step (2), pelletizing;

[0038] (4) The antistatic masterbatch after pelletizing was circulated, dried, mixed and evenly packed into bags to obtain the antistatic agent AT2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com