Finishing application of aminophenylsilsesquioxane tussah silk textile and modified finishing textile or fabric

A technology of silsesquioxane and aminophenyl, which is applied in fiber treatment, animal fiber, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

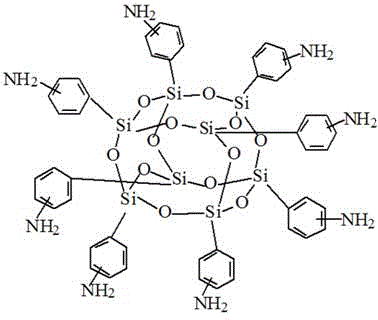

[0019] (1) Obtain a finishing solution containing aminophenylsilsesquioxane OAPS

[0020] Add OAPS into tetrahydrofuran and dissolve to obtain an OAPS solution with a concentration of 5.0 g / L. Add water to dilute the OAPS solution to obtain an OAPS aqueous solution with a concentration of 1.0 g / L. Take 10 ml of the OAPS aqueous solution and add 0.1 g of 1,4-butanediol to shrink Glyceryl ether and 0.05g sodium methylene dinaphthalene sulfonate diffusing agent, then add 90ml water to obtain 100ml finishing solution containing aminophenylsilsesquioxane OAPS;

[0021] (2) Modification and finishing of tussah silk

[0022] Immerse 2g of tussah silk into the finishing liquid prepared in step (1) at 40°C, raise the temperature to 60°C for 45 minutes, take out the finished tussah silk fabric, wash and dry it, and obtain the tussah silk raw material and its fabric modified finishing fabric .

Embodiment 2

[0024] (1) Obtain a finishing solution containing aminophenylsilsesquioxane OAPS

[0025] Add OAPS to tetrahydrofuran to dissolve to obtain an OAPS solution with a concentration of 10g / L, add water to dilute the OAPS solution to obtain an OAPS aqueous solution with a concentration of 2.0g / L, take 10ml of the OAPS aqueous solution, and add 0.2g of 1,4-butanediol Glycidyl ether BDGE and 0.1g sodium methylene dinaphthalene sulfonate diffusing agent, then add 90ml water to make 100ml finishing solution containing aminophenylsilsesquioxane OAPS;

[0026] (2) Modification and finishing of tussah silk

[0027] Immerse 2g of tussah silk into the finishing liquid prepared in step (1) at 40°C, raise the temperature to 70°C, and finish at this temperature for 60 minutes, take out the finished tussah silk fabric, wash, and dry to obtain the tussah silk raw material and its fabric Modified finishing fabric.

Embodiment 3

[0029] (1) Obtain a finishing solution containing aminophenylsilsesquioxane OAPS

[0030] Add OAPS to tetrahydrofuran to dissolve to obtain an OAPS solution with a concentration of 15g / L, add water to dilute the OAPS solution to obtain an OAPS aqueous solution with a concentration of 3.0g / L, take 10ml of the OAPS aqueous solution, and add 0.3g of 1,4-butanediol glycidol Ether BDGE and 0.15g sodium methylene dinaphthalene sulfonate diffusing agent, then add 90ml water to obtain 100ml aminophenyl silsesquioxane finishing solution;

[0031] (2) Modification and finishing of tussah silk

[0032] Immerse 2g of tussah silk fabric in the above finishing solution at 40°C, raise the temperature to 85°C, and finish at this temperature for 45 minutes, take out the finished tussah silk fabric, wash, and dry to obtain the tussah silk raw material and its fabric modified finishing fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com