Detection method for odor substances in exhaust gas of perfume and essence industry

A detection method and essence technology, applied in the direction of measuring devices, material separation, analysis of materials, etc., can solve problems such as the establishment of methods without a system, and achieve the effects of good air tightness, high efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

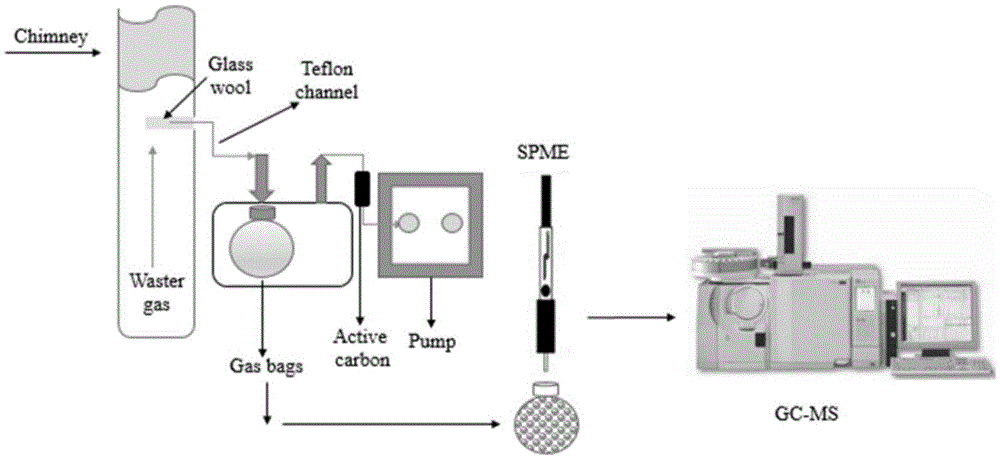

Method used

Image

Examples

Embodiment 1

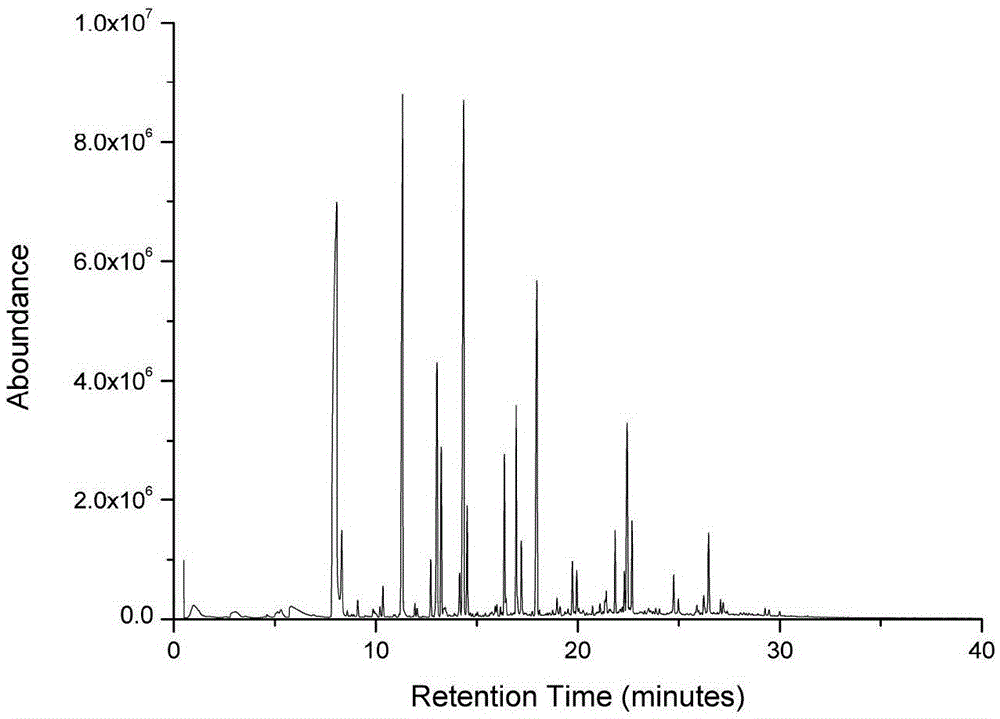

[0030] Embodiment 1: the detection of odor substance in the exhaust gas of the first flavor and fragrance company, first do blank test to air bag, then select volume 2L, PVF material sampling bag collects gas sample, select the SPME probe extraction sampling of CAR-PDMS-DVB coating The sample in the bag was kept for 1 hour, and desorbed in the GC inlet for 2 minutes. Gas chromatography-mass spectrometry analysis conditions are: chromatographic column: Rtx-5, injection 1uL, inlet temperature 260°C, ion source temperature 230°C, split ratio 10:1, flow rate 1mL / min. Temperature program: the initial temperature is 40°C, keep for 2min, increase the temperature to 200°C at a rate of 5°C / min, and keep for 5min. The scanning range of the mass spectrum is 40-400m / z. The detection process of odor substances in exhaust gas is as follows: figure 1 , detect the GC / MS total ion chromatogram as shown in figure 2 As shown, the odor compounds in the exhaust gas are shown in Table 1.

Embodiment 2

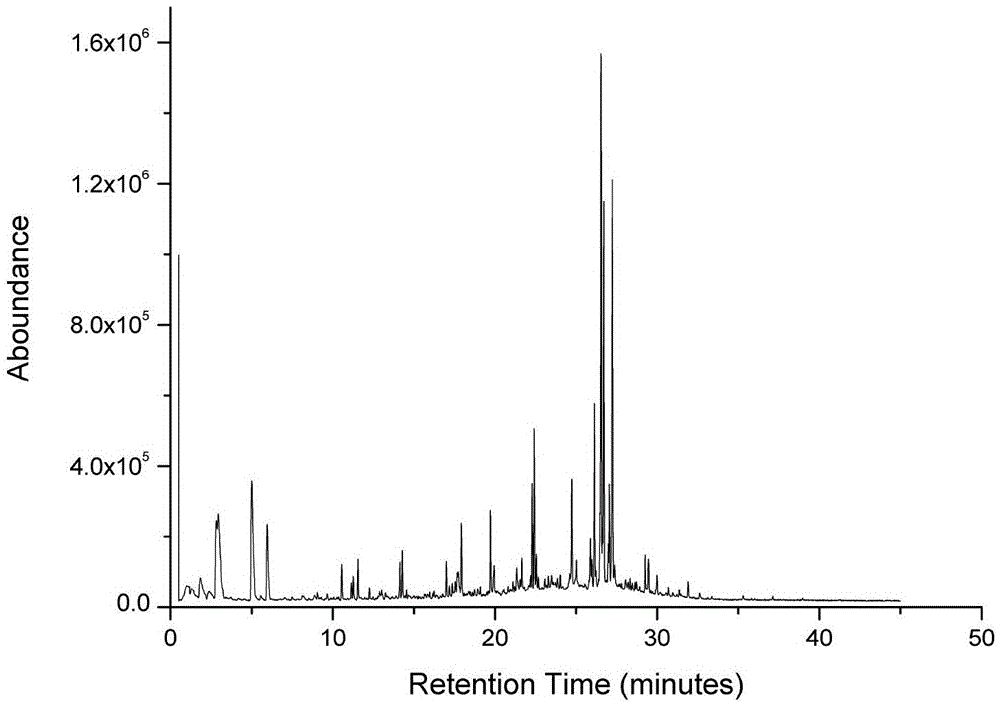

[0031] Embodiment 2: Odor substance detection in the exhaust gas of the second fragrance and essence company, first blank test is done to air bag, then select volume 2L, the sampling bag of PVDF material collects gas sample, selects the sample 1h in the SPME probe extraction sampling bag of PDMS coating , and desorbed at the GC inlet for 2min, the gas chromatography-mass spectrometry analysis conditions were: chromatographic column: Rtx-5, sample injection 1uL, inlet temperature 260°C, ion source temperature 230°C, split ratio 10:1, Flow rate 1 L / min. Programmable temperature rise: initial temperature is 40°C, keep for 2min, increase the temperature to 200°C at a rate of 5°C / min, keep for 5min, mass spectrometry scanning range is 40-400m / z. The total ion chromatogram of exhaust gas compounds is as follows: image 3 shown.

Embodiment 3

[0032] Example 3: Detection of odorous substances in the exhaust gas of Bing Petrochemical Company. Firstly, a blank test is performed on the air bag, and then a sampling bag with a volume of 2L is selected to collect the gas sample, and the SPME probe coated with PDMS-DVB is selected to extract the sampling bag. The sample was desorbed for 1 hour at the GC inlet for 2 minutes. The gas chromatography-mass spectrometry conditions were: chromatographic column: Rtx-5, 1uL injection, inlet temperature 260°C, ion source temperature 230°C, split ratio 50: 1. The flow rate is lml / min. Programmed temperature rise: the initial temperature is 60°C, keep for 2min, raise the temperature to 210°C at a rate of 6°C / min, keep for 5min, and the scanning range of the mass spectrum is 40-400m / z. Total ion chromatogram of exhaust gas compounds, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com