Reaction endpoint judgment device and five-step iodometry

A technology of reaction end point and judging device, which is applied in the direction of analysis by chemical reaction of materials, chemical analysis by titration method, material analysis by observing the influence on chemical indicators, etc., can solve the judgment error and influence of titration end point. To solve problems such as changes in the color of the titration end point, to achieve the effect of convenient operation, avoiding subjective limitations, and improving sensitivity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

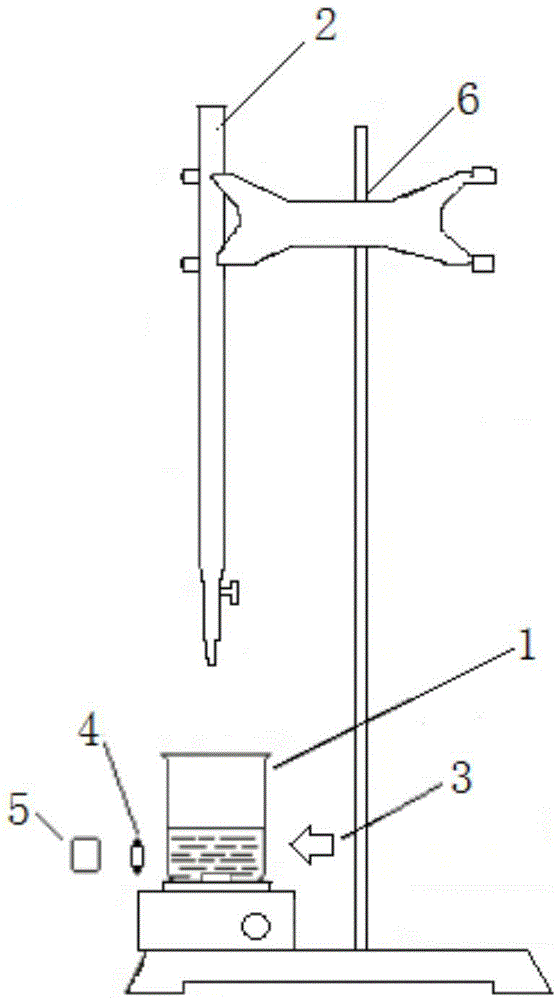

[0031] This embodiment provides a reaction terminal judging device, which includes a reaction vessel 1, a burette 2 arranged above the reaction vessel 1, the burette 2 is connected to the burette holder 6 through a burette clamp, and a burette arranged on the reaction vessel 1. A monochromatic light source 3 on one side of the outside and a photoelectric receiver 4 located on the other side of the reaction vessel 1 opposite the side of the single-sided light source 3, the photoelectric receiver 4 is connected to a data processing system 5; wherein the reaction vessel 1 is transparent container, the monochromatic light emitted by the monochromatic light source 4 passes through the solution in the reaction container 1 and is received by the photoelectric receiver 4; the data processing system 5 performs data processing on the electrical signal received by the photoelectric receiver Analyze and calculate to obtain the absorbance of the solution. The light wavelength emitted by the...

Embodiment 2

[0034] Present embodiment provides a kind of five-step iodometric method, comprises the steps:

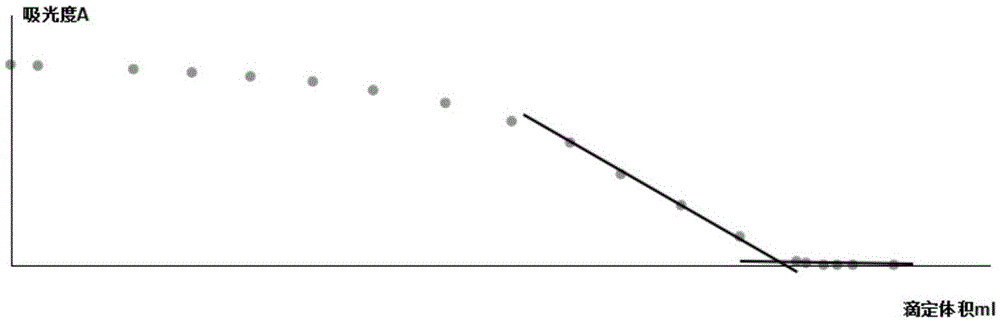

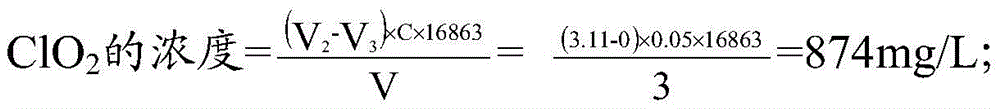

[0035] 1) Mix 3ml of the sample to be tested with 200ml of water and adjust the pH to 7 with phosphate buffer solution, add 10ml of potassium iodide solution with a concentration of 100g / L, and titrate with a standard solution of sodium thiosulfate with a concentration of 0.05mol / L , until the mixed solution becomes pale yellow, adopt the reaction terminal judging device, continue to titrate the sodium thiosulfate standard solution in the mixed solution, and continue to titrate excessively after the solution absorbance value reaches the mutation point, such as figure 2 As shown, draw two straight lines using the least squares method or table tool before and after the mutation point, and calculate the intersection point value of the two straight lines, which is the added volume of sodium thiosulfate at the end of the titration, and record this volume as the added thiosulfate The vo...

Embodiment 3

[0066] Present embodiment provides a kind of five-step iodometric method, comprises the steps:

[0067] 1) Mix 5ml of the sample to be tested with 300ml of water and adjust the pH to 7 with a phosphate buffer solution, add 20ml of potassium iodide solution with a concentration of 100g / L, and titrate with a standard solution of sodium thiosulfate with a concentration of 0.1mol / L , until the mixed solution becomes pale yellow, adopt the reaction end point judging device, continue to titrate the sodium thiosulfate standard solution in the mixed solution, and continue to titrate excessively after the solution absorbance value reaches the mutation point, and calculate the thiosulfate added when the titration end point Sodium sulfate standard solution volume V1, the sodium thiosulfate standard solution volume that adds is V1, V1 is 1.20ml among the present embodiment;

[0068] 2) Gradually add 2ml of hydrochloric acid solution with a concentration of 2.5N to the solution obtained in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com