Chromium-doped lithium titanate as cathode material

A cathode material, chromium doping technology, applied in the direction of titanate, alkali metal titanate, positive electrode, etc., can solve problems such as limited conductivity, improve safety, improve capacity reversibility, and high dimensional stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

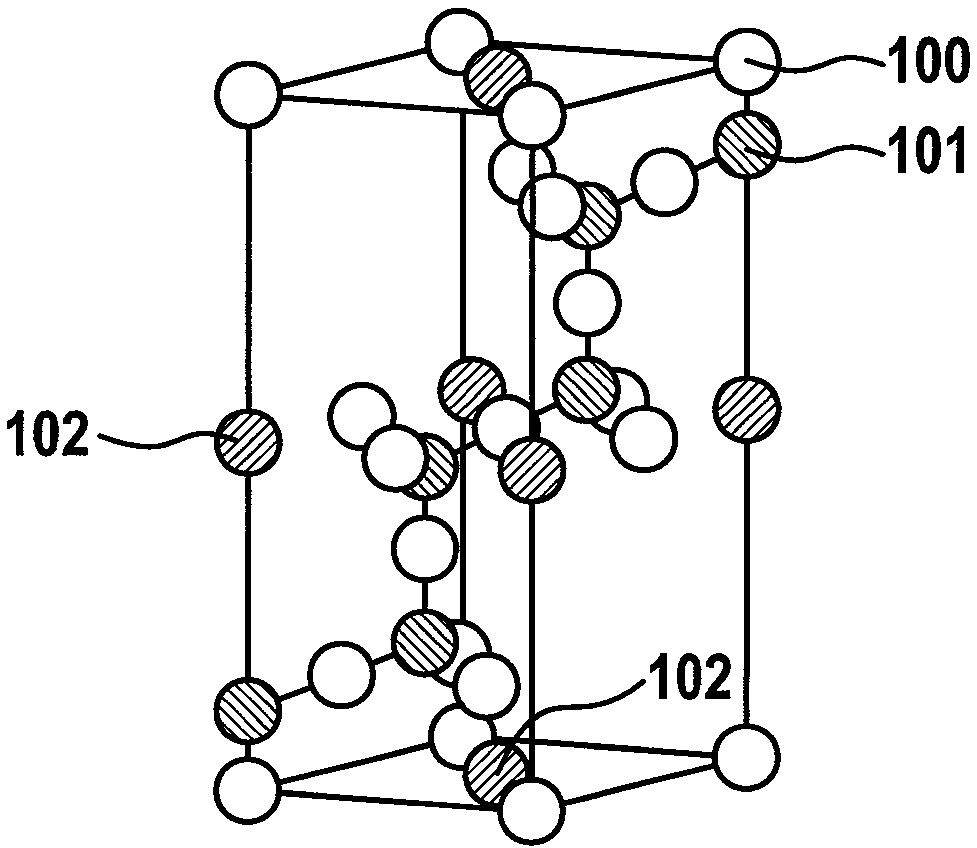

[0067] A. Solid Synthesis

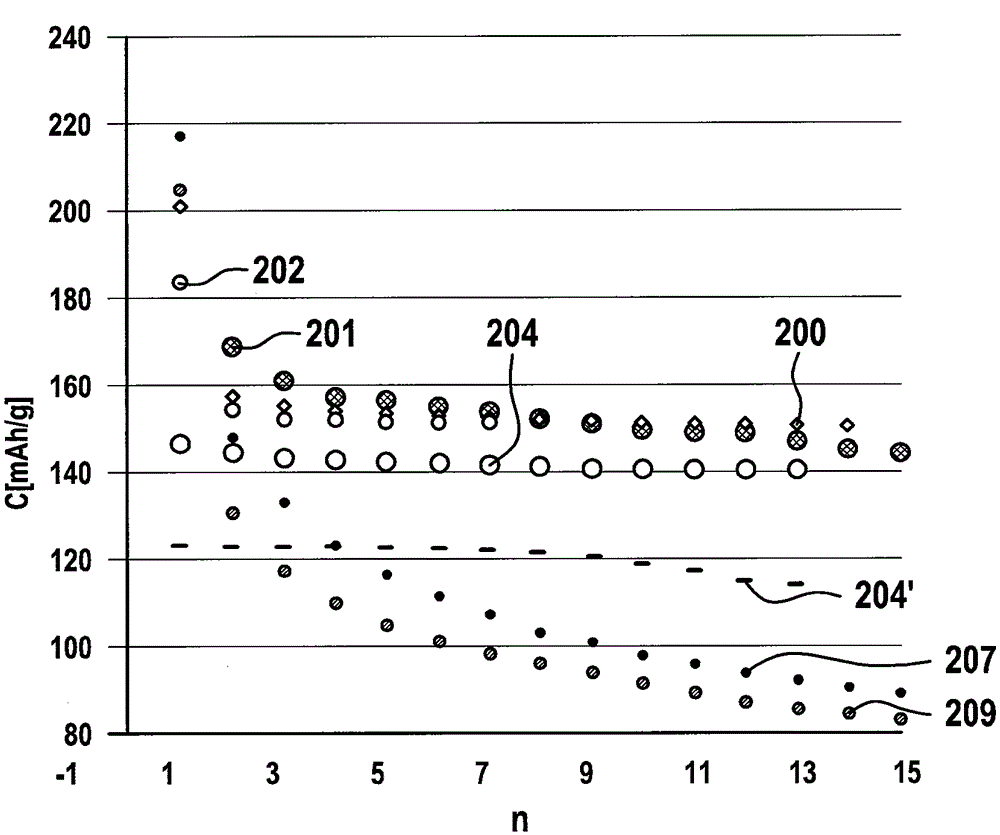

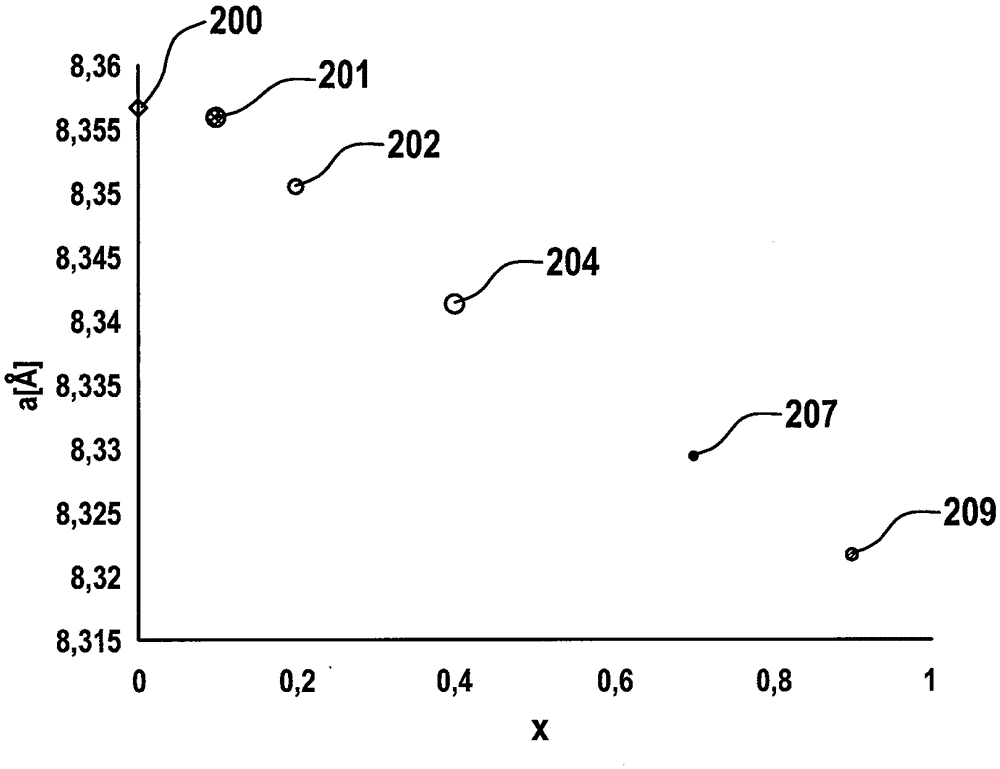

[0068] 1. Chromium-doped lithium titanate particles: Li with x=0.1, 0.2, 0.4, 0.7 and 0.9 4-x Ti 5-2x Cr 3x O 12 solid synthesis

[0069] Synthesis of a series of chemical formula Li by means of solid synthesis especially of ceramics 4-x Cr 3x Ti 5-2x O 12 of chromium-doped lithium titanate with x = 0.1, 0.2, 0.4, 0.7 and 0.9.

[0070] Here, lithium carbonate (Li 2 CO 3 ), titanium dioxide (TiO 2 ) and chromium (III) oxide (Cr 2 O 3 ) was mixed with 40 ml of isopropanol and ground with a ball mill with zirconium dioxide balls at 150 rpm for 2 hours and then dried at 70° C. by means of a rotary evaporator. The residue is then calcined in air at 800°C in a furnace. After roasting and furnace cooling, samples were taken and ground by hand. The resulting product was green.

[0071] 2. Chromium-doped lithium titanate particles with oxygen vacancies: Li with x = 0.2 and 0.4 4-x Ti 5-2x Cr 3x O 12-δ solid synthesis

[0072] Synthesis 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com