Preparation method of nanometer light-emitting material with CdS/Cr-doped structure

A nano-luminescent material and airflow direction technology, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve the effects of easy operation, strong process controllability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

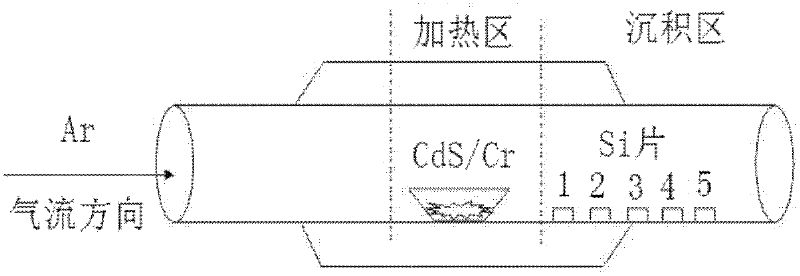

[0028] Weigh a certain amount of CdS powder and Cr powder with a molar ratio of 1:1, mix them in an agate mortar, and grind them for 15 minutes to make them evenly mixed. Put the ground mixture into a quartz boat, take 5 pieces of gold-plated Si slices, each Si slice is 1cm apart, and place them on the other side of the quartz boat along the direction of the gas, and put the reactant quartz boat into the heating area, the Si sheet is placed in the deposition area (such as figure 1 ). Vacuumize the reaction device first, and then pass argon to an atmospheric pressure; evacuate the vacuum to below -0.08MPa in a cycle operation, and pass argon twice; adjust the argon flow rate to 350sccm to make it stable, and then adjust the temperature of the heating furnace Regulator, set the reaction temperature to 900°C and the reaction time to 30 minutes. Deposited products were obtained on Si wafers.

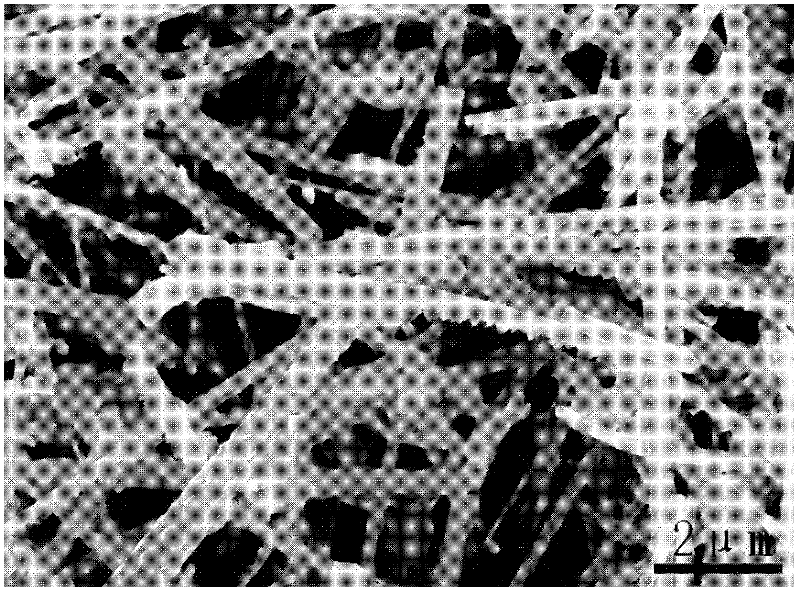

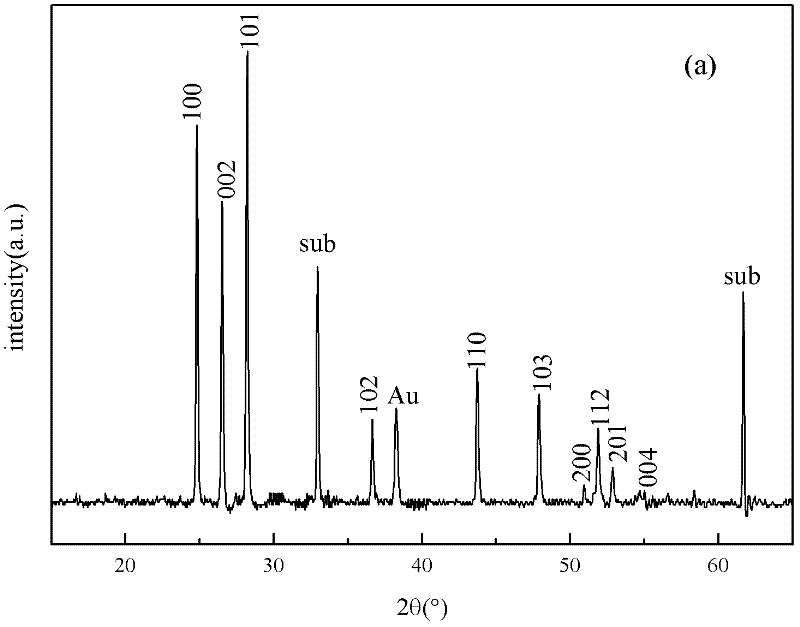

[0029] The resulting product was directly observed under a scanning electron microsco...

Embodiment 2

[0031] As in Example 1, a certain amount of CdS powder and Cr powder were weighed, mixed in an agate mortar, and ground for 15 minutes to make them evenly mixed. Put the ground mixture into a quartz boat, take 5 pieces of gold-plated Si slices, each Si slice is 1cm apart, and place them on the other side of the quartz boat along the direction of the gas, and put the reactant quartz boat into the heating area, the Si sheet is placed in the deposition area (such as figure 1 ). Vacuumize the reaction device first, and then pass argon to an atmospheric pressure; evacuate the vacuum to below -0.08MPa in a cycle operation, and pass argon twice; adjust the argon flow rate to 350sccm to make it stable, and then adjust the temperature of the heating furnace Regulator, set the reaction temperature to 900°C and the reaction time to 40 minutes. Deposited products were obtained on Si wafers. The morphology, structure, element composition and luminescent properties of the product are the...

Embodiment 3

[0033] As in Example 1, a certain amount of CdS powder and Cr powder were weighed, mixed in an agate mortar, and ground for 15 minutes to make them evenly mixed. Put the ground mixture into a quartz boat, take 5 pieces of gold-plated Si slices, each Si slice is 1cm apart, and place them on the other side of the quartz boat along the direction of the gas, and put the reactant quartz boat into the heating area, the Si sheet is placed in the deposition area (such as figure 1 ). Vacuumize the reaction device first, and then pass argon to an atmospheric pressure; evacuate the vacuum to below -0.08MPa, and pass argon 3 times in a cycle operation; adjust the argon flow rate to 350 sccm to make it stable, and then adjust the temperature of the heating furnace Regulator, set the reaction temperature to 910°C and the reaction time to 30 minutes. Deposited products were obtained on Si wafers. The morphology, structure, element composition and luminescent properties of the product are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com