Equipment for growth of horizontal chromium doped semi-insulation gallium arsenide

A semi-insulating, gallium arsenide technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of affecting the crystal growth rate of crystal growth, increase the cost of crystal growth, increase the difficulty of equipment manufacturing, etc., and achieve crystal growth. The effect of low cost, high crystallization rate and simplified equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

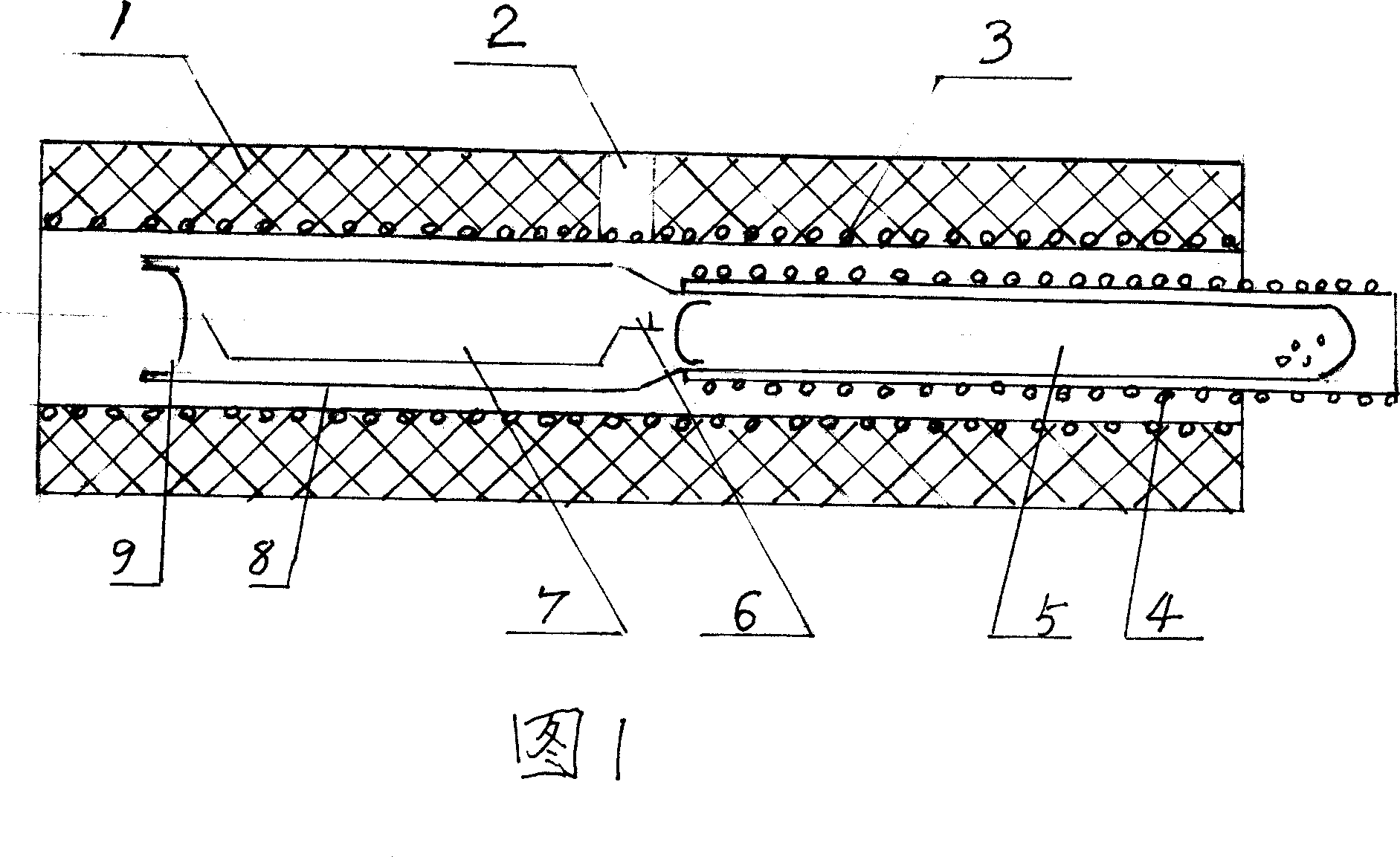

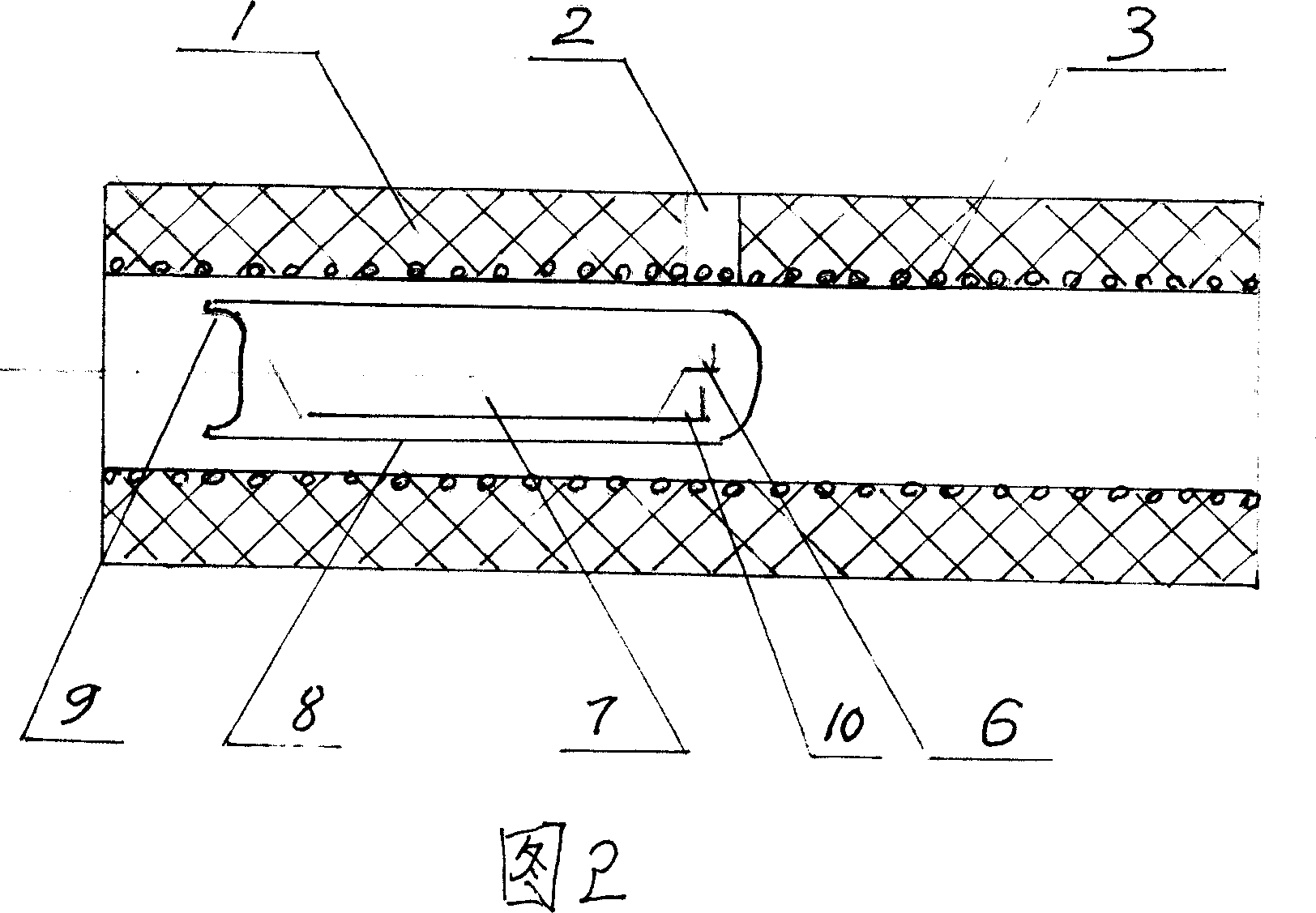

[0007] The present invention maintains the vapor pressure by strictly controlling the amount of arsenic in the arsenic pressure chamber 10 on the quartz reaction boat 7 in the reflection chamber 8, and the whole system is kept above the condensation point of arsenic during crystal growth, and the change of the arsenic pressure is affected by the temperature change The influence of arsenic is very small, the amount of arsenic used to control the arsenic pressure is maintained at 5-10‰ of the original amount of gallium arsenide polycrystalline, and the amount of pure chromium doped is controlled at 3-5‰.

[0008] Its technological process is:

[0009] 1. Use emery to quickly and evenly spray the inner cavity of the arsenic reaction boat until the filament of the 100W incandescent lamp can be clearly observed at a distance of 15-30 cm across the quartz reaction boat;

[0010] 2. The sandblasted quartz reaction boat is treated with acid, ultrasonically cleaned, dried, placed in mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com