A kind of instant coffee with low caffeine and preparation method thereof

An instant coffee and low caffeine technology, applied in the direction of coffee extraction, etc., can solve the problems of high cost, loss of coffee flavor, unsatisfactory, etc., and achieve the effect of low processing cost, no solvent residue, and reduced caffeine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

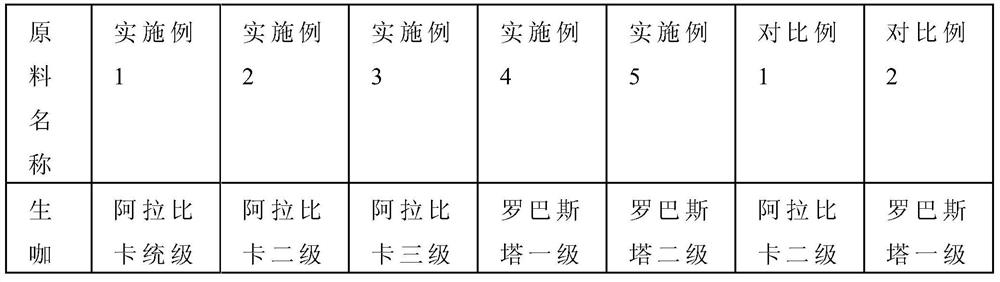

Embodiment 1

[0038] Weigh 1000kg Arabica beans, and make them according to the following steps.

[0039] (1) Soak the above coffee beans for 1 hour with 2000kg of production water at 20°C, and remove the soaking water;

[0040] (2) Steam the coffee beans prepared in step (1) under normal pressure with steam at 100°C for 1 hour, and spray 200kg of hot water (90-100°C) once every 0.5h;

[0041] (3) Take out the coffee beans prepared in step (2) to dry in the air, and air-dry to a moisture content of 12%;

[0042] (4) Roast the coffee beans prepared in step (3) to the first burst (bean temperature 180-190°C) using conventional roasting parameters, and keep the bean temperature for 10 minutes until the moisture content of the roasted beans is <6.0%, and the color value is 100± 2 is enough;

[0043] (5) Grinding the roasted beans prepared in step (4) to 20 mesh with a coffee bean grinder;

[0044] (6) Pre-wet the ground coffee powder prepared in step (5) with 500kg hot water (80°C) for 20 mi...

Embodiment 2

[0048] Weigh 1000kg of Arabica secondary beans and make them according to the following steps.

[0049] (1) Use 2000kg of 25°C production water to soak the coffee beans for 1 hour, and remove the soaking water;

[0050] (2) Steam the coffee beans prepared in step (1) under normal pressure with steam at 100°C for 1 hour, and spray 200kg of hot water (90-100°C) once every 0.5h;

[0051] (3) Take out the coffee beans prepared in step (2) to dry in the air, and air-dry to a moisture content of 12%;

[0052] (4) Roast the coffee beans prepared in step (3) to first burst (bean temperature 180-190°C) using conventional roasting parameters, and keep the bean temperature for 10 minutes until the moisture content of the roasted beans is <6.0%, and the color value is 95± 2 is enough;

[0053] (5) Grinding the roasted beans prepared in step (4) to 15 mesh with a coffee bean grinder;

[0054] (6) Pre-wet the ground coffee powder prepared in step (5) with 500kg hot water (100°C) for 20 min...

Embodiment 3

[0058] Weigh 1000kg of third-grade Arabica beans and make them according to the following steps.

[0059] (1) Soak coffee beans for 1 hour with 2000kg 30°C production water, then remove the soaking water;

[0060] (2) Pressurize the coffee beans prepared in step (1) with steam at 110°C for 1 hour, and spray 200kg of hot water (90-100°C) once every 0.2h;

[0061] (3) Take out the coffee beans prepared in step (2) to dry in the air, and air-dry to a moisture content of 12%;

[0062] (4) Use conventional roasting parameters to roast the coffee beans prepared in step (3) to the first burst (bean temperature 180-190°C), keep the bean temperature for 8 minutes, and then bake to the second burst (bean temperature 200-220°C) ), until the moisture content of the roasted beans is <6.0%, and the color value is 85±2;

[0063] (5) Grinding the roasted beans prepared in step (4) to 15 mesh with a coffee bean grinder;

[0064] (6) Pre-wet the ground coffee powder prepared in step (5) with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com