Supported manganese-based low-temperature denitrification catalyst and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of poor catalytic activity and poor dispersion, and achieve high and low temperature denitrification activity, low Live temperature, reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

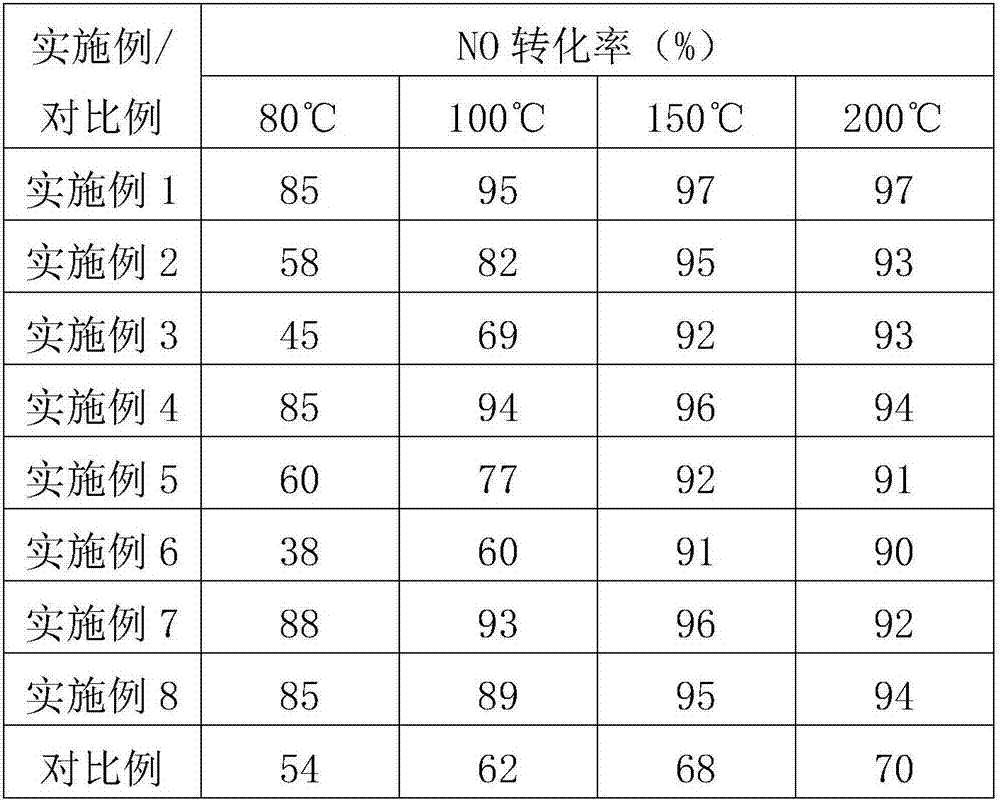

Examples

Embodiment 1

[0027] 1) 1.79g of manganese nitrate and 0.87g of cerium nitrate were dissolved in 10mL of water to form a mixed solution of manganese salt and cerium salt, and 7.17g of Span-80, 10.75g of Trion X-100, 8.5g of n-hexanol and 90mL of cyclic Add hexane to the above mixed solution, stir until clear, and obtain a microemulsion containing manganese salt and cerium salt; wherein, the molar ratio of water, mixed surfactant, n-hexanol, and cyclohexane is 1:0.06:0.15:1.5;

[0028] 2) Add 91.7g of titanium sol (mass fraction: 18.0%) into the above microemulsion, stir for 1h, then adjust its pH value to 10 with ammonia water, place in an oven and heat at 85°C for 5h to obtain xerogel;

[0029] 3) Grinding the xerogel and calcining at 500°C for 3h to obtain CeO 2 -MnO x / TiO 2 denitrification catalyst.

[0030] The active component of the denitration catalyst is CeO 2 -MnO x Nanoparticles, the average particle size of the nanoparticles is 11nm. The specific surface of the denitration...

Embodiment 2

[0032] 1) 1.79g of manganese nitrate and 0.33g of ferric chloride were dissolved in 10mL of water to form a mixed solution of manganese salt and iron salt, and 7.17g of Span-80, 10.75g of Trion X-100, 8.5g of n-hexanol and 90mL of cyclic Add hexane to the above mixed solution, stir until clear, and obtain a microemulsion containing manganese salt and iron salt; wherein, the molar ratio of water, mixed surfactant, n-hexanol, and cyclohexane is 1:0.06:0.15:1.5;

[0033] 2) Add 91.7g of titanium sol (mass fraction: 18.0%) into the above microemulsion, stir for 1h, then adjust its pH value to 10 with ammonia water, place in an oven and heat at 87°C for 5h to obtain xerogel;

[0034] 3) Grinding the xerogel and calcining at 550°C for 3 hours to obtain Fe 2 o 3 -MnO x / TiO 2 denitrification catalyst.

[0035] The active component of the denitration catalyst is Fe 2 o 3 -MnO x Nanoparticles, the average particle size of the nanoparticles is 6nm. The specific surface of the de...

Embodiment 3

[0037]1) 1.79g of manganese nitrate and 0.26g of cobalt chloride were dissolved in 10mL of water to form a mixed solution of manganese salt and cobalt salt, 7.17g of Span-80, 10.75g of Trion X-100, 8.5g of n-hexanol and 90mL of cyclohexane Alkanes were added to the above mixed solution, stirred until clarification, and a microemulsion containing manganese salt and cobalt salt was obtained; wherein, the molar ratio of water, mixed surfactant, n-hexanol, and cyclohexane was 1:0.06:0.15:1.5;

[0038] 2) Add 91.7g of titanium sol (mass fraction: 18.0%) into the above microemulsion, stir for 1h, then adjust its pH value to 10 with ammonia water, place it in an oven and heat at 90°C for 6h to obtain a xerogel;

[0039] 3) Grinding the xerogel and calcining at 580°C for 3h to obtain CoO-MnO x / TiO 2 denitrification catalyst.

[0040] The active component of the denitration catalyst is CoO-MnO x Nanoparticles, the average particle size of the nanoparticles is 16nm. The specific su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com