Supported gold catalyst, preparation method thereof, and p-aminophenol preparation method

A technology for p-aminophenol and gold catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, etc., can solve the problems of large particles, influence of catalyst activity, etc. The method is simple, the preparation cost is reduced, and the aggregation effect is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] According to the preparation method described in the second aspect of the present invention, when the molar ratio of the amount of gold source, protective agent, reducing agent and silicon dioxide is 1:10-250:0.5-5:200-700, it can To obtain the supported gold catalyst of the present invention, in a preferred situation, the molar ratio of the gold source, protective agent, reducing agent and silicon dioxide is 1:10-100:1-2.5:300-500.

[0029] According to the preparation method described in the second aspect of the present invention, the amount of water used is not particularly limited, as long as the gold source, protective agent and reducing agent can be fully dissolved, preferably, the amount of water used can make the gold source The molar concentration of gold in the reaction solution of the protective agent and the reducing agent is 0.5-2mmol / L, more preferably 0.5-1mmol / L.

[0030] According to the preparation method described in the second aspect of the present i...

Embodiment 1

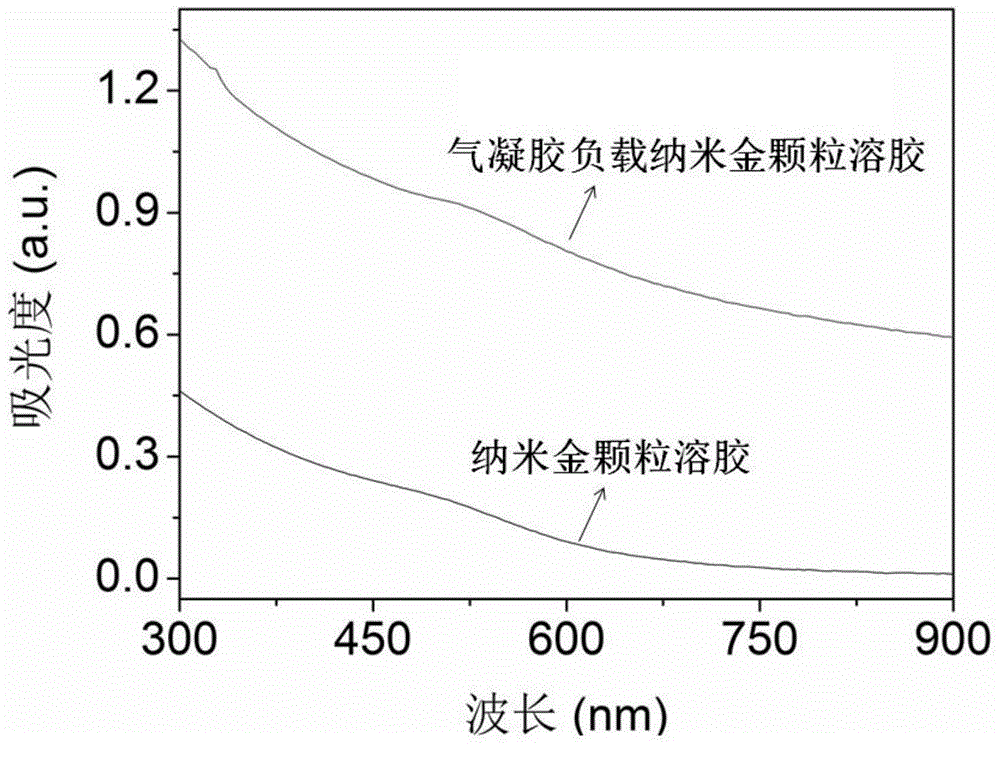

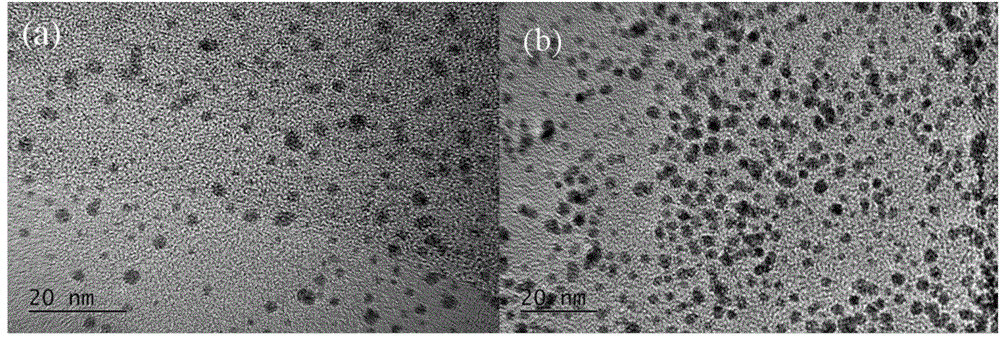

[0057] Take 5mL of 2mM HAuCl 4 Aqueous solution, adding 5 mL of polyvinylpyrrolidone (PVP) k-30 aqueous solution with a concentration of 20 mM, stirring vigorously at a speed of 1200 r / min for 5 min under an ice bath, and then adding 0.6 mL of NaBH with a concentration of 40 mM to the mixed solution 4 The aqueous solution was vigorously stirred at a speed of 1200r / min for 2min to obtain a brown gold nanoparticle sol.

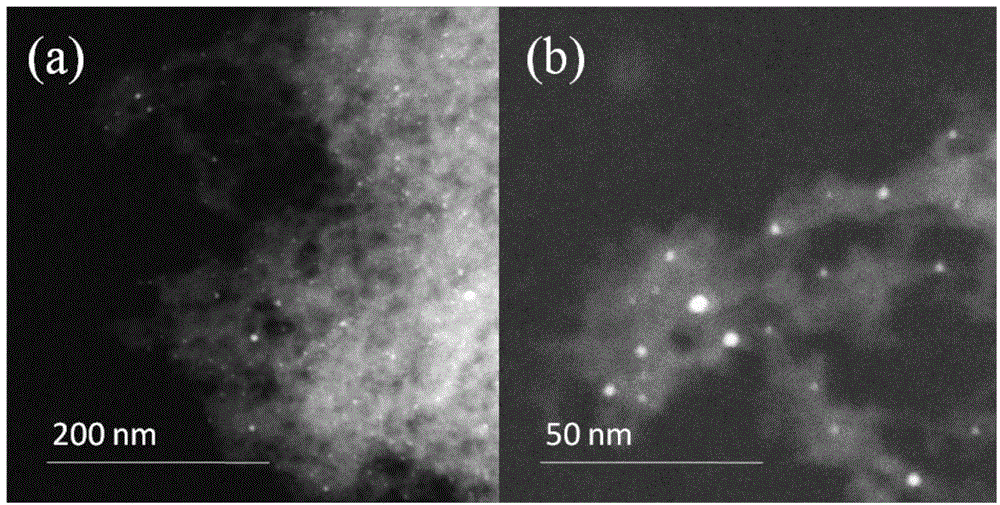

[0058] Another 200mg silica airgel (porosity 95%, average pore diameter 20nm, specific surface area 750m2) passed through a 70 mesh sieve 2 / g), dispersed in the mixed solution of 10mL water and 4mL ethanol, after gently stirring at a speed of 450r / min for 5min, add the prepared nano-gold particle sol, and gently stir at a speed of 450r / min for 12h.

[0059] The resulting mixture was allowed to stand for stratification, the upper layer was a colorless aqueous phase, and the lower layer was a brown gel phase. The upper layer was decanted, and the insoluble matt...

Embodiment 2

[0063] Take 5mL of 2mM HAuCl 4Aqueous solution, add 5 mL of polyvinyl alcohol (PVA) aqueous solution with a concentration of 11 mM, stir vigorously at a speed of 1000 r / min for 3 min in an ice bath, and then add 0.5 mL of NaBH with a concentration of 30 mM to the mixed solution 4 The aqueous solution was vigorously stirred at a speed of 1000 r / min for 1 min to obtain a brown gold nanoparticle sol.

[0064] Another 250mg silica airgel (porosity 92%, average pore diameter 30nm, specific surface area 720m2) passed through a 40 mesh sieve 2 / g), dispersed in the mixed solution of 10mL water and 2mL ethanol, after gently stirring at a speed of 400r / min for 3min, add the prepared nano-gold particle sol, and gently stir at a speed of 450r / min for 10h.

[0065] The resulting mixture was allowed to stand for stratification, the upper layer was a colorless aqueous phase, and the lower layer was a brown gel phase. The upper layer was decanted, and the insoluble matter of the obtained g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com