A carbon fiber polymer composite pressure-resistant cabin and its manufacturing process

A technology of composite material and manufacturing process, which is applied in underwater operation equipment, ship construction, ships, etc., can solve problems such as complex operating conditions and harsh environments, achieve superior performance and price ratio, and improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

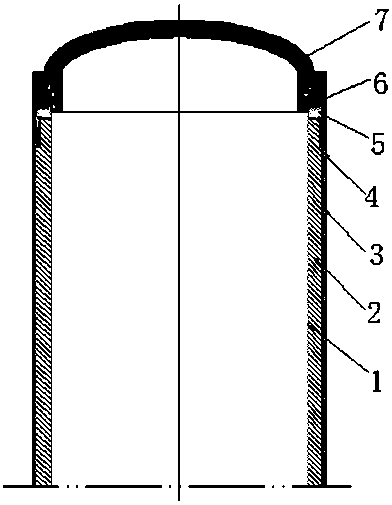

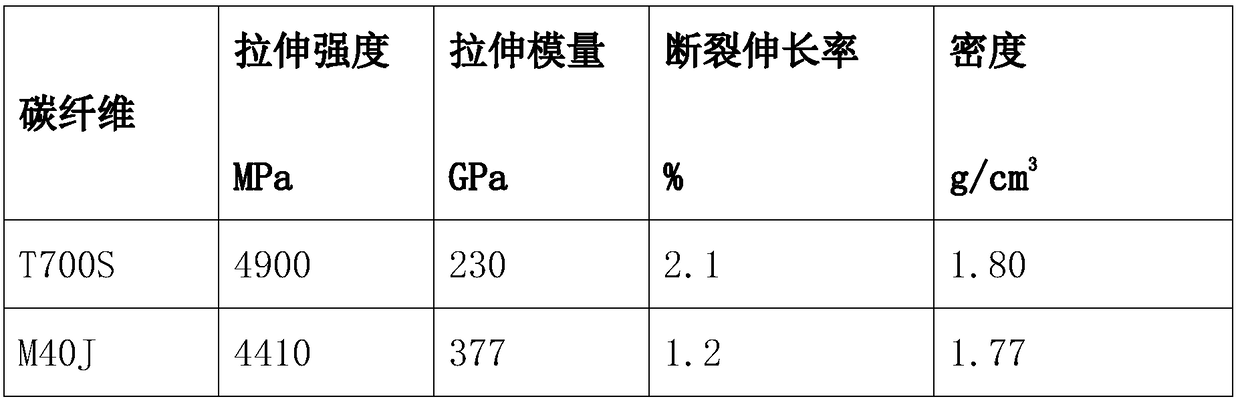

[0030] Such as figure 1 As shown, a carbon fiber polymer composite pressure-resistant cabin body, the pressure-resistant cabin body includes two parts: a cylindrical cabin body and two end covers located at both ends of the cabin body, characterized in that: the cabin body is composed of To the outside are the inner protective layer, the carbon fiber barrel, the anti-seepage layer, and the outer protective layer. The two ends of the cabin are sealed and connected to the end cover through the connector and the sealing ring, and the cabin and the connector are glued. The inner protective layer is made of NBR-modified epoxy resin and the outer protective layer is made of ultra-high molecular weight polyethylene, and its thickness is 2-3mm. The thickness range can be determined according to the use environment. The material of the anti-seepage layer is afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com