Method for preparing sodium silicate by using common pulverized fuel ash from circulating fluidized bed

A common circulation and fly ash technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of high energy consumption, high alkali consumption, low dissolution rate, etc., and achieve simple manufacturing process and large processing capacity , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

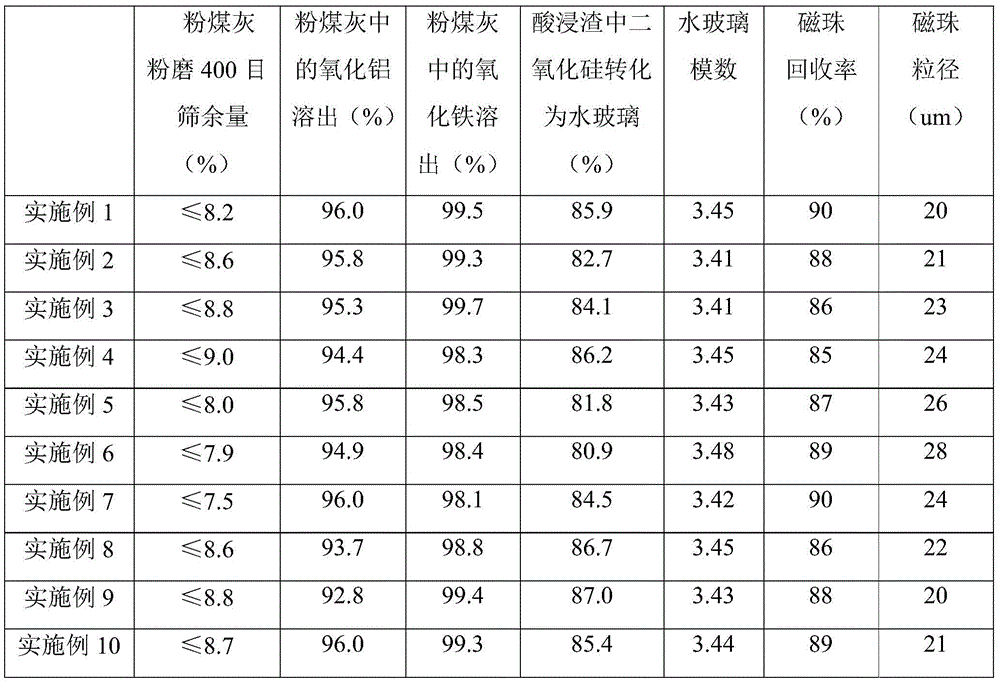

Examples

Embodiment 1

[0030] Embodiment 1, fly ash is through 4 times of magnetic separation, then through mechanical grinding, mill speed is 1200r / min, the fine powder powder that obtains after pulverization 4min, then with 82% sulfuric acid by solid-to-liquid ratio 5: 4 Mix and react at 200°C for 4 hours; after the reaction is completed and cooled to room temperature, add water according to the solid-to-liquid ratio of fly ash to water at 1:3, heat to 90°C, stir for 2 hours, filter cake with suction, and use The solid-to-liquid ratio of fly ash and water is 1:1 for washing to obtain the solution of ferric sulfate and aluminum sulfate and high silica acid leaching residue; the concentration of acid leaching residue to solution is 1:1 and the concentration is 10.5%. The caustic soda solution is put into a high-pressure reactor and heated for 10 hours at a reaction temperature of 180°C; after cooling to room temperature, filter and wash the solid slag with a small amount of water to obtain water glas...

Embodiment 2

[0031] Embodiment 2, the fly ash is through 5 times of magnetic separation, then through mechanical grinding, the mill speed is 1100r / min, the fine powder powder obtained after grinding for 4min, then with 85% sulfuric acid by solid-liquid ratio 6: 5 mixed and reacted at 200°C for 5 hours; after the reaction was completed and cooled to room temperature, add water according to the solid-to-liquid ratio of fly ash and water at 1:3, heat to 85°C, stir for 2 hours, filter cake with suction, and use The solid-to-liquid ratio of fly ash and water is 3:2 for washing to obtain the solution of ferric sulfate and aluminum sulfate and high-silicate leaching residue; the solid-liquid ratio of acid leaching residue to solution is 4:5, and the concentration is 10%. The caustic soda solution is put into a high-pressure reactor and heated for 8 hours at a reaction temperature of 180°C; after cooling to room temperature, filter and wash the solid slag with a small amount of water to obtain wate...

Embodiment 3

[0032] Embodiment 3, fly ash is through 4 times of magnetic separation, then through mechanical grinding, mill speed is 1000r / min, the fine powder powder that obtains after pulverization 4min, then with 85% sulfuric acid by solid-liquid ratio 6: 5 mixed and reacted at 200°C for 5 hours; after the reaction was completed and cooled to room temperature, add water according to the solid-to-liquid ratio of fly ash and water at 1:4, heat to 80°C, stir for 2 hours, filter cake with suction, and use The solid-to-liquid ratio of fly ash and water is 3:2 for washing to obtain the solution of ferric sulfate and aluminum sulfate and high silica acid leaching residue; the solid-liquid ratio of acid leaching residue to solution is 2:3 and the concentration is 11%. The caustic soda solution was put into a high-pressure reactor and heated for 8 hours at a reaction temperature of 200°C; after cooling to room temperature, it was filtered and the solid slag was washed with a small amount of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com