Crosslinked fluorine polymer based dielectric elastomer compound material and preparation method therefor

A fluoropolymer and composite material technology, applied in the field of dielectric elastomer materials, can solve the problems of increased leakage conduction loss, inconspicuousness, increased deformation, etc. The effect of magnitude reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

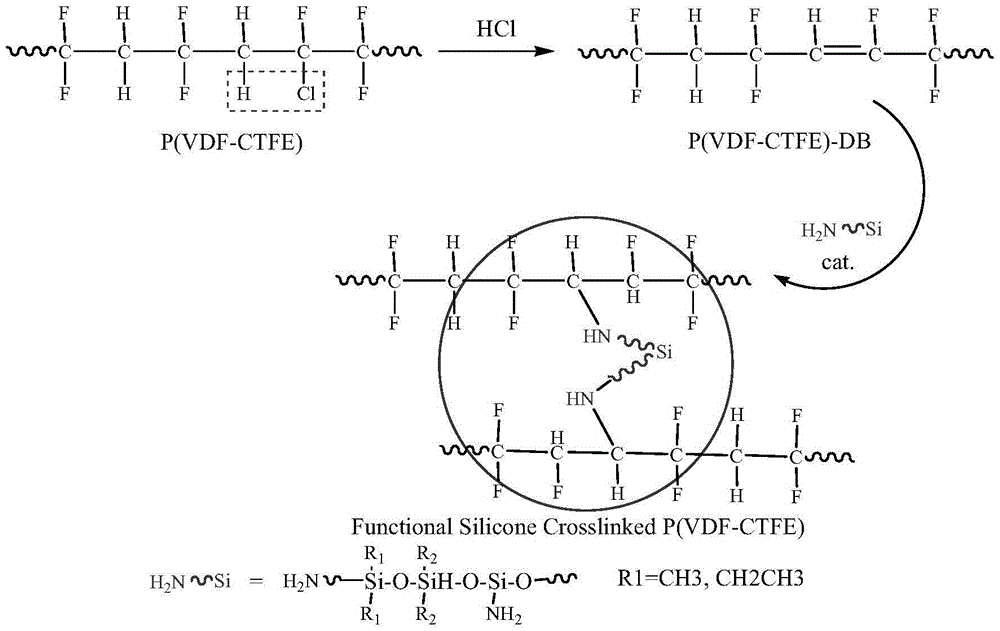

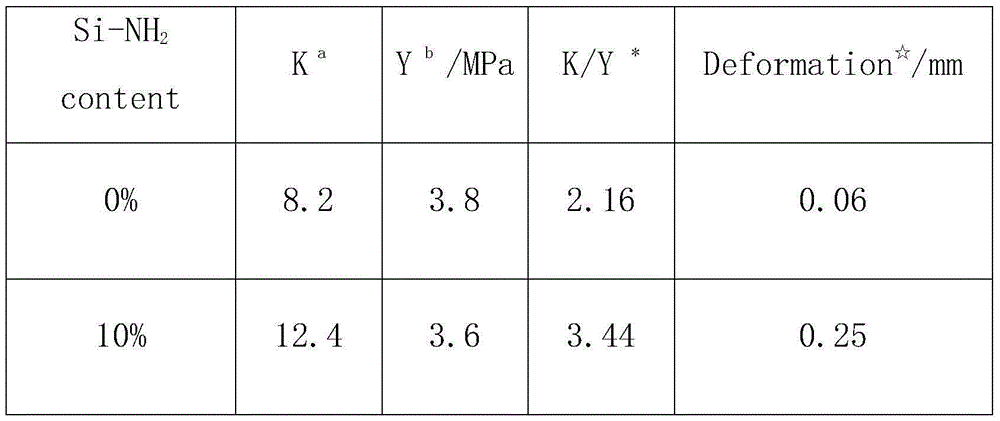

Method used

Image

Examples

Embodiment 1

[0022] The raw material components in this example include 90 parts by weight of a fluoropolymer matrix, 9 parts by weight of a functional crosslinking agent and 1 part by weight of a catalyst.

[0023] The preparation method of this embodiment includes the following steps: adding 100 ml of ethyl acetate into a 200 ml flask, then adding 9 g of poly(vinylidene fluoride-chlorotrifluoroethylene) containing internal double bonds, and vigorously stirring for 30 min; after dissolving, Add 0.9 g of aminosiloxane functional crosslinking agent molecules (molecular weight is about 2000) dropwise under strong stirring, and continue to stir at room temperature for 30 minutes; then gradually add 0.1 g of catalyst water, and stir for 8 hours at 60 °C; After that, the reaction solution was filtered, and then cast on a glass plate. The glass plate was placed in a uniform thermal environment, gradually heated to 80° C., and dried for 8 hours to remove the solvent. The aminosiloxane addition-cr...

Embodiment 2

[0026] The raw material components in this example include 60 parts by weight of a fluoropolymer matrix, 38 parts by weight of a functional crosslinking agent and 2 parts by weight of a catalyst.

[0027] The preparation method of this embodiment includes the following steps: adding 80ml of dimethylformamide to a 200ml flask, then adding 6g of poly(vinylidene fluoride-trifluoroethylene-chlorotrifluoroethylene) containing internal double bonds, and vigorously stirring 30min; after dissolving, add 3.8g mercaptopolyacrylate functional crosslinking agent molecules (molecular weight is about 20000) dropwise under strong stirring, and continue stirring for 30min at room temperature; then gradually add 0.2g catalyst ethanol, and stir the reaction at 50°C 8h; after cooling to room temperature, the reaction solution was filtered, then cast on a glass plate, placed in a uniform thermal environment, gradually heated to 90°C, dried for 8h to remove the solvent. The polyacrylate cross-link...

Embodiment 3

[0030] In this example, the raw material components in parts by mass include: 77 parts of fluoropolymer matrix, 20 parts by weight of functional crosslinking agent and 3 parts of catalyst.

[0031] The preparation method of this embodiment includes the following steps: adding 120 ml of tetrahydrofuran to a 200 ml flask, then adding 7.7 g of poly(vinylidene fluoride-hexafluoropropylene) containing internal double bonds, and vigorously stirring for 30 minutes; after dissolving, vigorously stirring 2g of polyisoprene functional crosslinking agent molecules (molecular weight of about 50,000) were gradually added under the hood, stirring was continued for 30min at room temperature; then 0.3g of catalyst benzoyl peroxide was gradually added dropwise, and the reaction was stirred at 40°C for 8h; After reaching room temperature, the reaction solution was filtered, and then cast on a glass plate. The glass plate was placed in a uniform thermal environment, gradually heated to 60°C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com