Manufacturing method of antibacterial air-permeable foaming insole material

A manufacturing method and insole technology, which is applied in insoles, footwear, textiles, and papermaking, can solve the problems of airtightness and easy breeding of bacteria, and achieve the effects of improving affinity, good solubility, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

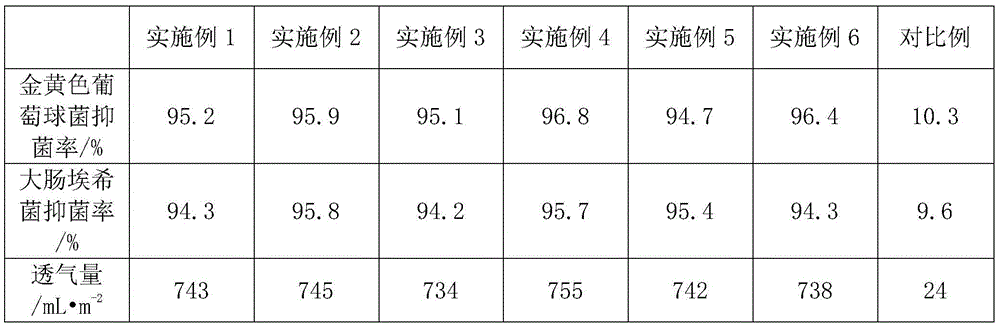

Examples

Embodiment 1

[0025] Manufacture antibacterial and breathable foam insole material according to the following steps:

[0026] (1) Cut watermelon vines into watermelon vines with a length of 5cm and a diameter of 5mm, soak them in distilled water for 2 hours, heat to 100°C, keep them warm for 3 hours, take them out, drain them, and put them into the flash explosion device Adjust the pressure to 0.9MPa, release the pressure after maintaining the pressure for 30 minutes, wash it with distilled water after taking it out, and obtain the watermelon vine crude fiber after draining;

[0027] (2) Add the watermelon vine crude fiber that step (1) obtains in alkaline hydrogen peroxide solution, and this alkaline hydrogen peroxide solution contains the hydrogen peroxide that mass concentration is 3% and the sodium hydroxide that mass concentration is 3%, is placed on the magnetic stirrer After heating to 80°C, leaching for 4 hours, filtering and drying the obtained precipitate to obtain alkalized water...

Embodiment 2

[0032] Manufacture antibacterial and breathable foam insole material according to the following steps:

[0033] (1) Cut watermelon vines into watermelon vines with a length of 5cm and a diameter of 5mm, soak them in distilled water for 2 hours, heat to 100°C, keep them warm for 3 hours, take them out, drain them, and put them into the flash explosion device Adjust the pressure to 0.9MPa, release the pressure after maintaining the pressure for 30 minutes, wash it with distilled water after taking it out, and obtain the watermelon vine crude fiber after draining;

[0034] (2) Add the watermelon vine crude fiber that step (1) obtains in alkaline hydrogen peroxide solution, and this alkaline hydrogen peroxide solution contains the hydrogen peroxide that mass concentration is 3% and the sodium hydroxide that mass concentration is 3%, is placed on the magnetic stirrer After heating to 80°C, leaching for 4 hours, filtering and drying the obtained precipitate to obtain alkalized water...

Embodiment 3

[0039] Manufacture antibacterial and breathable foam insole material according to the following steps:

[0040] (1) Cut watermelon vines into watermelon vines with a length of 5cm and a diameter of 5mm, soak them in distilled water for 2 hours, heat to 100°C, keep them warm for 3 hours, take them out, drain them, and put them into the flash explosion device Adjust the pressure to 0.9MPa, release the pressure after maintaining the pressure for 30 minutes, wash it with distilled water after taking it out, and obtain the watermelon vine crude fiber after draining;

[0041] (2) Add the watermelon vine crude fiber that step (1) obtains in alkaline hydrogen peroxide solution, and this alkaline hydrogen peroxide solution contains the hydrogen peroxide that mass concentration is 3% and the sodium hydroxide that mass concentration is 3%, is placed on the magnetic stirrer After heating to 80°C, leaching for 4 hours, filtering and drying the obtained precipitate to obtain alkalized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com