A dense deoxidized body for pollution-free deoxidation of metal melts and its preparation method

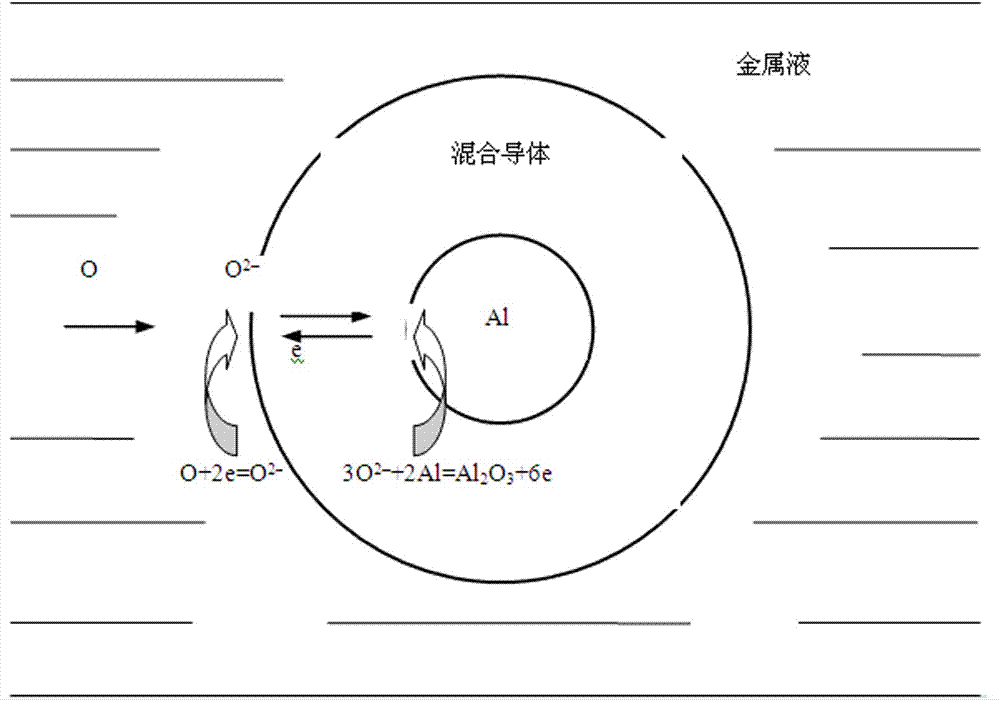

A metal melt and deoxidizer technology, applied in the field of metallurgy, can solve the problems of reducing the gasification rate and loss of aluminum body, affecting the deoxidation rate, and failing to meet the deoxidation demand of metal melt, so as to achieve the effect of avoiding pollution and high deoxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

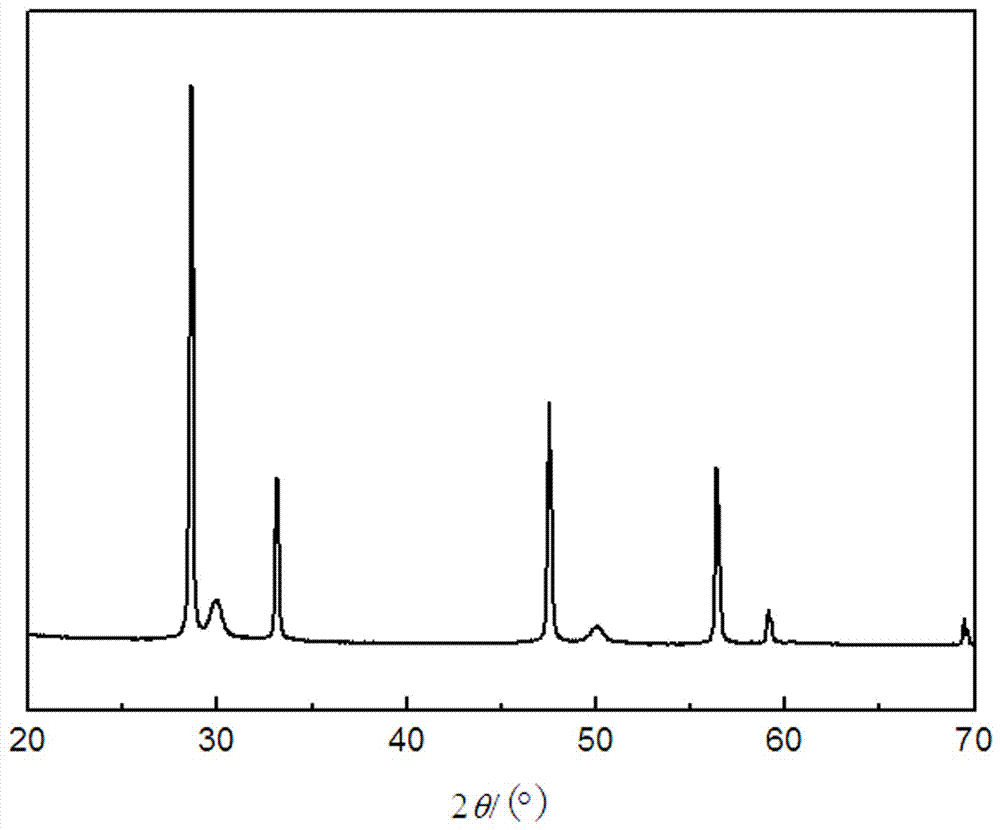

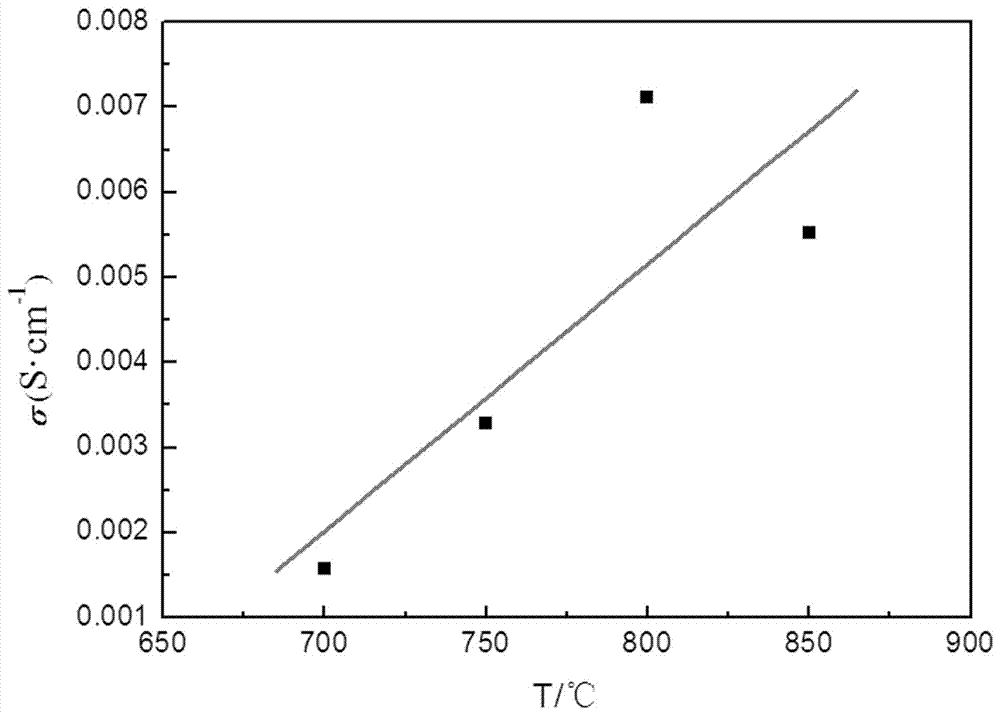

[0034] Dense deoxidizer for non-pollution deoxidation of metal melts, molecular formula is Ce 0.75 Zr 0.25 o 2 , its chemical composition according to mass percentage is: 14.26% of zirconium element, 65.72% of cerium element, and the balance is oxygen and unavoidable impurities. Its preparation method is carried out according to the following process steps:

[0035] (1) Preparation of composite oxalate precursor: ZrOCl 2 ·8H 2 O, Ce 2 (CO 3 ) 3 and C 2 h 4 o 4 2H 2 O by n(ZrOCl 2 ·8H 2 O):n(Ce 2 (CO 3 ) 3 ):n(C 2 h 4 o 4 2H 2 (2) = 0.25: 0.375: 0.375 ratio feeding, after mixing evenly, adding Tween 60 with a mass fraction of 5%, ball milling until the particle size reaches ≤ 100 μm, to obtain a composite oxalate precursor;

[0036] (2) Preparation of mixed conductive powder: the composite oxalic acid precursor was dried at a constant temperature of 70°C, then calcined at 600°C for 4 hours, and then ground again after cooling until the particle size reached ≤1...

Embodiment 2

[0046] Dense deoxidizer for non-pollution deoxidation of metal melts, molecular formula is Cr 0.5 Zr 0.5 o 2 , its chemical composition according to mass percentage is: 44.02% of zirconium element, 25.09% of chromium element, and the balance is oxygen and unavoidable impurities. Its preparation method is carried out according to the following process steps:

[0047] (1) Preparation of composite oxalate precursor: ZrOCl 2 ·8H 2 O, Cr 2 (CO 3 ) 3 and C 2 h 4 o 4 2H 2 O by n(ZrOCl 2 ·8H 2 O):n(Cr 2 (CO 3 ) 3 ):n(C 2 h 4 o 4 2H 2 (0)=0.5: 0.25: 0.75 ratio feeding, after mixing evenly, add the Tween 60 that mass fraction is 10%, ball milling reaches ≤ 100 μm to particle diameter, obtains composite oxalate precursor;

[0048] (2) Preparation of mixed conductive powder: the composite oxalic acid precursor was dried at a constant temperature of 60°C, then calcined at 600°C for 6 hours, and then ground again after cooling until the particle size reached ≤100 μm to o...

Embodiment 3

[0053] Dense deoxidizer for pollution-free deoxidation of metal melts, molecular formula is Tb 0.25 Zr 0.75 o 2 , its chemical composition according to mass percentage is: 48.82% of zirconium element, 28.35% of terbium element, and the balance is oxygen and unavoidable impurities. Its preparation method is carried out according to the following process steps:

[0054] (1) Preparation of composite oxalate precursor: ZrOCl 2 ·8H 2 O, Tb 3 o 4 and C 2 h 4 o 4 2H 2 O by n(ZrOCl 2 ·8H 2 O):n(Tb 3 o 4 ):n(C 2 h 4 o 4 2H 2 (0)=0.75: 0.125: 1.125 ratio feeding, after mixing evenly, add the Tween 60 that mass fraction is 15%, ball milling reaches ≤ 100 μm to particle diameter, obtains composite oxalate precursor;

[0055] (2) Preparation of mixed conductive powder: the composite oxalic acid precursor was dried at a constant temperature of 80°C, then calcined at 600°C for 4 hours, and then ground again after cooling until the particle size reached ≤100 μm to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com