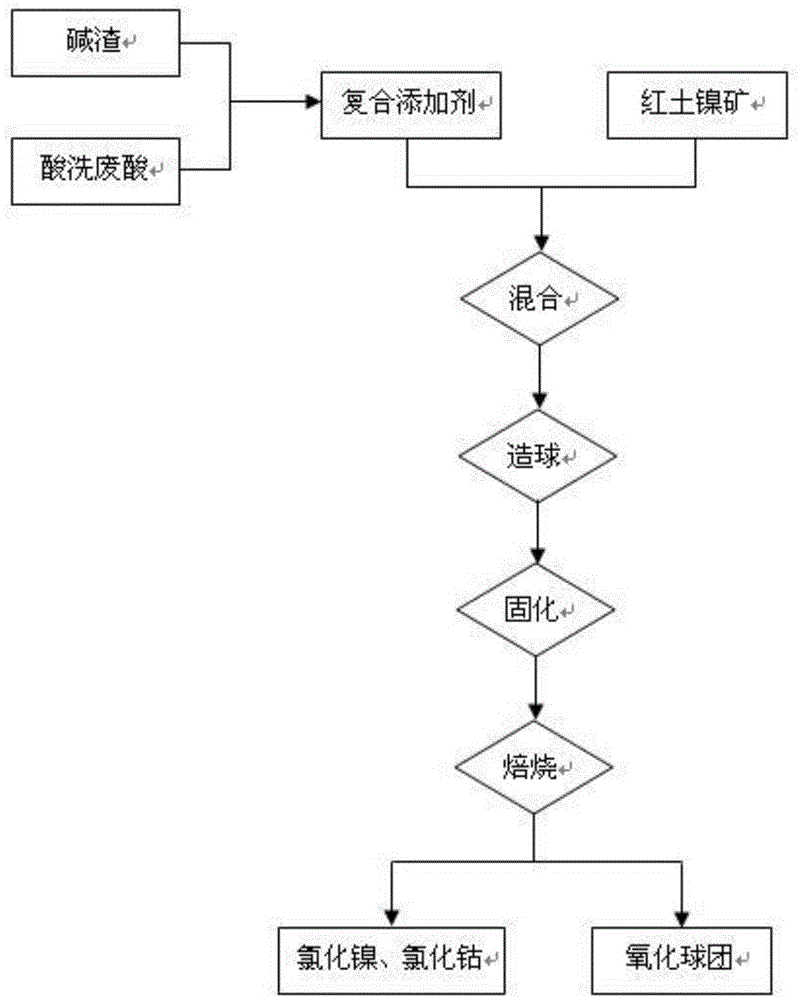

Method for extracting nickel and cobalt from nickel laterite ore through caustic sludge and waste pickling liquid

A technology of laterite nickel ore and pickling waste liquid, which is applied in the field of resource recycling and mineral processing, can solve the problems of surrounding environmental hazards, and achieve the effects of reducing production costs, saving process costs, and excellent chlorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of composite additive: Take 10g of alkali slag and add it to 30ml of pickling waste liquid (that is, the solid-to-liquid ratio is 1:3), stir and react at a stirring rate of 120r / min for 30min, and obtain the composite additive after the reaction is completed;

[0065] (2) The composite additive is added to the transition type laterite nickel ore, wherein the transition type laterite nickel ore is crushed to ≤100 mesh particles and accounts for 80-90wt% of the total mass, and the addition of the composite additive is 1 / 2 of the transition type laterite nickel ore quality 30wt%, and then granulated on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8 to 12 mm, and the gained laterite nickel ore green pellets were allowed to stand and cool for 9 hours;

[0066] (3) placing the solidified laterite nickel ore raw pellets in a muffle furnace for chlorination and roasting at 1050° C. for 120 minutes, and obtaining alkaline pellet...

Embodiment 2

[0069](1) Preparation of composite additive: Take 10g of alkali slag and add it to 40ml of pickling waste liquid (that is, the solid-to-liquid ratio is 1:4), stir and react at a stirring rate of 120r / min for 30min, and obtain the composite additive after the reaction is completed;

[0070] (2) The composite additive is added to the transition type laterite nickel ore, wherein the transition type laterite nickel ore is crushed to ≤100 mesh particles and accounts for 80-90wt% of the total mass, and the addition of the composite additive is 1 / 2 of the transition type laterite nickel ore quality 40wt%, then granulating on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8 to 12 mm, and the gained laterite nickel ore green pellets were allowed to stand and cool for 8 hours;

[0071] (3) placing the solidified laterite nickel ore raw pellets in a muffle furnace for chlorination and roasting at 1000° C. for 100 min, and obtaining alkaline pellets after ...

Embodiment 3

[0074] (1) Preparation of composite additive: Take 10 g of alkali residue and add it to 50 ml of pickling waste liquid (that is, the solid-to-liquid ratio is 1:5), stir and react at a stirring rate of 120 r / min for 30 minutes, and obtain a composite additive after the reaction is completed;

[0075] (2) The composite additive is added to the transition type laterite nickel ore, wherein the transition type laterite nickel ore is crushed to ≤100 mesh particles and accounts for 80-90wt% of the total mass, and the addition of the composite additive is 1 / 2 of the transition type laterite nickel ore quality 50wt%, and then granulated on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8 to 12 mm, and the gained laterite nickel ore green pellets were allowed to stand and cool for 9 hours;

[0076] (3) placing the solidified laterite nickel ore green pellets in a muffle furnace for chlorination and roasting at 1050° C. for 80 minutes, and obtaining alkal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com