Method for wet separation of electronic components in discarded printed circuit board and tin stripping agent

A technology for discarding circuit boards and electronic components, applied in the direction of improving process efficiency, etc., can solve the problems of weak oxidation of tin stripper, slow tin stripping speed, damage to components, etc., to achieve improved dissolution rate, low corrosion, Dissolution-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

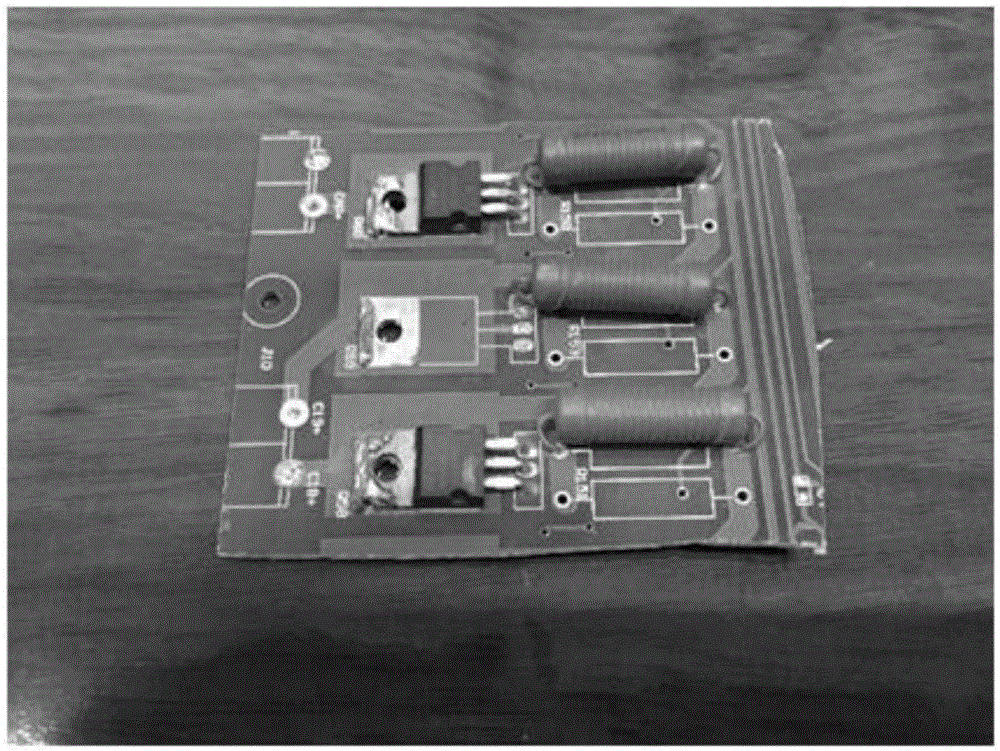

Image

Examples

Embodiment 1

[0035] A method for wet separation of electronic components in waste circuit boards of the present invention and an embodiment of the tin stripper, comprising the following steps:

[0036] 1) Prepare reagents: Dissolve sodium hydroxide and sodium citrate in water to form a solution I with a concentration of sodium hydroxide of 200 g / L and a concentration of sodium citrate of 20 g / L. The volume of this solution I is 500 ml.

[0037] 2) Separation of tin stripping: Clean and dry the 6cm×6cm discarded desktop computer circuit boards with electronic components, put them into 500ml solution I, and put the discarded Add tert-butyl hydroperoxide to the solution I of the circuit board and fully stir it. At the same time, use an ultrasonic wave to vibrate the solution, filter it after 30 minutes of treatment, separate the electronic components from the circuit board, and count the dissolution rate of the solder, the separation rate of the components and components. Failure rate. Its s...

Embodiment 2

[0039] A method for wet separation of electronic components in waste circuit boards of the present invention and an embodiment of the tin stripper, comprising the following steps:

[0040] 1) Prepare reagents: Dissolve sodium hydroxide and sodium citrate in water to form a solution I with a concentration of sodium hydroxide of 250 g / L and a concentration of potassium citrate of 30 g / L. The volume of this solution I is 500 ml.

[0041] 2) Separation of tin stripping: Clean and dry the 6cm×6cm discarded desktop computer circuit boards with electronic components, put them into 500ml solution I, and put the discarded circuit boards at a flow rate of 4mL / min at 50°C. Add hydrogen peroxide to the solution I of the board and stir it fully. At the same time, use ultrasonic vibration to oscillate the solution, filter it after 30 minutes of treatment, separate the electronic components from the circuit board, and count the dissolution rate of the solder, the separation rate and damage ra...

Embodiment 3

[0043] A method for wet separation of electronic components in waste circuit boards of the present invention and an embodiment of the tin stripper, comprising the following steps:

[0044] 1) Prepare reagents: Dissolve sodium hydroxide and sodium citrate in water to form a solution I with a concentration of sodium hydroxide of 250 g / L and a concentration of sodium citrate of 40 g / L. The volume of this solution I is 500 ml.

[0045] 2) Separation of tin stripping: Clean and dry the 6cm×6cm discarded desktop computer circuit board with electronic components, put it into 500ml solution I, and put the discarded circuit board at a flow rate of 6mL / min at 70°C. Add tert-butyl hydroperoxide to the solution I of the board and stir it fully. At the same time, use ultrasonic vibration to oscillate the solution, filter it after 30 minutes of treatment, separate the electronic components from the circuit board, and count the dissolution rate of the solder, the separation rate and damage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com