Method for determining lead content of feed mildew preventive

A determination method and technology of antifungal agent, applied in the direction of measuring device, analytical material, color/spectral characteristic measurement, etc., can solve the problems of high use cost, low precision and high price of feed and feed additive enterprises, and achieve detection Real and reliable data, short digestion time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings. This implementation case is carried out on the premise of the technology of the present invention, and the detailed implementation and specific operation process are now given to illustrate the inventiveness of the present invention, but the protection scope of the present invention is not limited to the following examples.

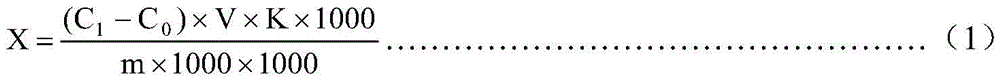

[0025] One, the assay method of lead content in the antifungal agent for feed of the present invention, comprises the steps:

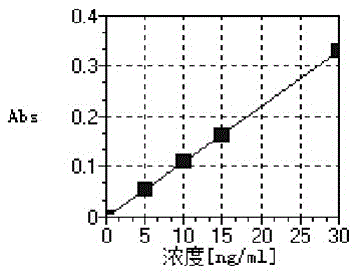

[0026] 1) prepare the lead standard aqueous solution of gradient concentration, adjust the acid concentration in each lead standard aqueous solution to 5~15% with acid;

[0027] 2) Borohydride, potassium ferricyanide, sodium hydroxide and lead stabilizer are dissolved in water to prepare lead determination reagent; wherein, the borohydride, potassium ferricyanide, sodium hydroxide, lead stabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com