Low-thermal-resistance connector-less feed array antenna and implementation method therefor

An array antenna and connector-less technology, which is applied to specific array feeding systems, antennas, antenna arrays, etc., can solve problems such as increased loss, connector loss, and impact on array reliability, so as to improve electrical performance and reliability performance, avoiding failure, and eliminating the effect of signal transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

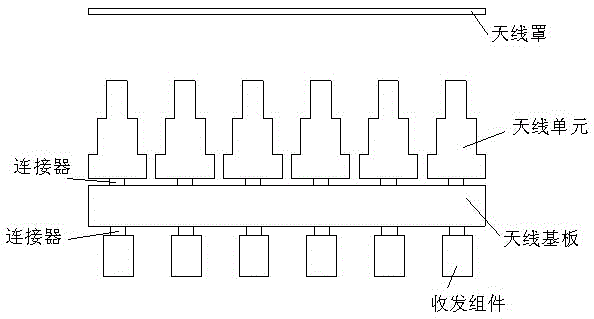

[0022] Taking the design of an array antenna as an example, the structure of the array antenna designed according to the traditional array antenna is shown in figure 1 , the antenna unit and the transceiver assembly are electrically connected through a connector, the antenna unit and the transceiver assembly are installed on both sides of the antenna substrate, and the connector is installed in the antenna substrate through a brazing process.

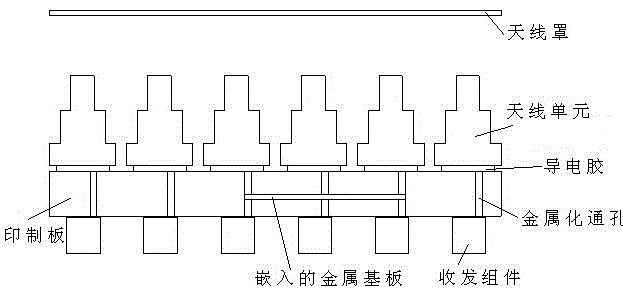

[0023] According to the method of the present invention, the metal substrate with better thermal conductivity is processed into an antenna unit, which is pressed on the surface of the printed board or embedded in the middle of the multilayer printed board, and its typical structure is as follows figure 2 As shown, the embedded metal substrate itself can also be used as a ground layer, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com