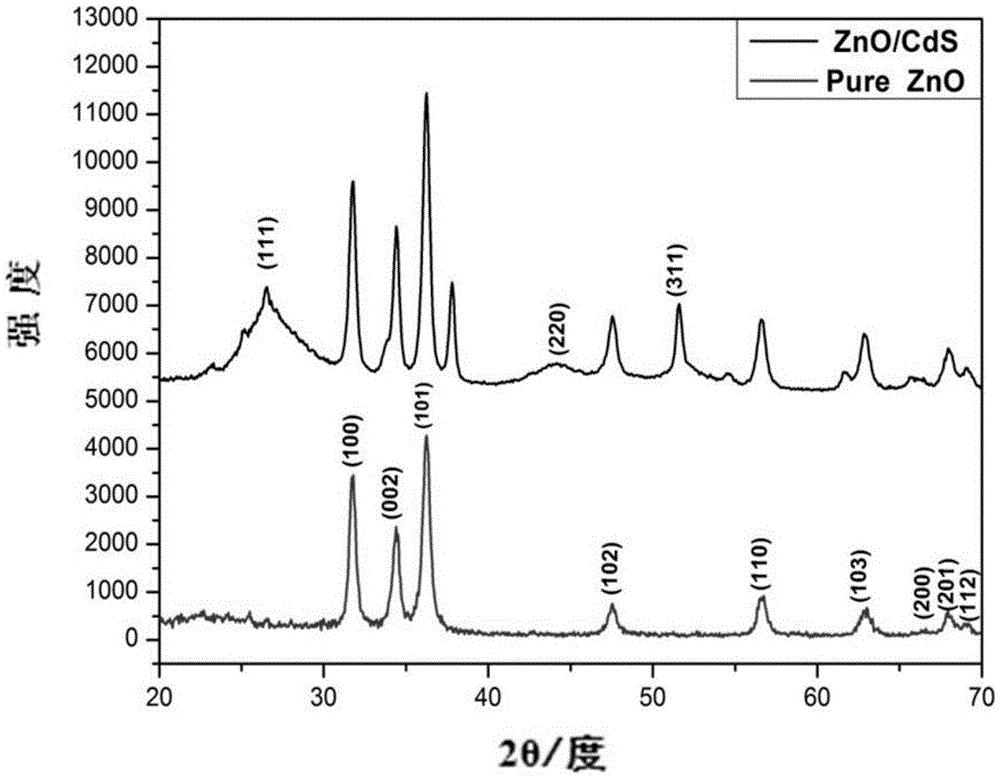

Cadmium sulfide and zinc oxide core-shell multilayer nanorod array photocatalytic material and preparation method thereof

A technology of nanorod array and photocatalytic material, which is applied in the field of cadmium sulfide-zinc oxide core-shell multilayer nanorod array photocatalytic material and its preparation, can solve the problem of few surface active sites, high recombination probability of photogenerated carriers, Low utilization rate of visible light and other problems, to achieve the effect of improved photocatalytic performance, simple preparation method, and controllable loading amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A cadmium sulfide-zinc oxide core-shell multilayer nanorod array photocatalytic material, the preparation method of which comprises the following steps:

[0036] 1) 0.75molZn(Ac) 2 (zinc acetate) and 0.75molC 2 h 7 Disperse NO (ethanolamine) in 50mL of ethylene glycol methyl ether, transfer it to a two-necked flask, pass in inert gas Ar and keep stirring, then place it in an oil bath at 60°C for 30 minutes, and transfer it to an Erlenmeyer flask after cooling to room temperature Medium aging for 24h, to get ZnO sol;

[0037] 2) The obtained ZnO sol is spin-coated onto the clean FTO glass surface by a desktop homogenizer under the condition of low speed and high speed (low speed is 600r / min, high speed is 1300r / min);

[0038] 3) Put the glass sheet evenly coated with ZnO sol in step 2) into a muffle furnace and heat it at a heating rate of 5°C / min to 300°C for 10 minutes, then cool it naturally to room temperature and take it out to obtain ZnO crystal seeds;

[0039]...

Embodiment 2

[0049] A cadmium sulfide-zinc oxide core-shell multilayer nanorod array photocatalytic material, the preparation method of which comprises the following steps:

[0050] 1) 0.75molZn(Ac) 2 (zinc acetate) and 1.5molC 2 h 7 Disperse NO (ethanolamine) in 50mL of ethylene glycol methyl ether, transfer to a two-necked flask, pass in an inert gas Ar and keep stirring, then place it in an oil bath at 45°C for 40 minutes, and transfer it to an Erlenmeyer flask after cooling to room temperature Medium aging for 48h, to get ZnO sol;

[0051] 2) The obtained ZnO sol is spin-coated onto the clean FTO glass surface by a desktop homogenizer under the condition of low speed and high speed (low speed is 600r / min, high speed is 1300r / min);

[0052] 3) Put the glass sheet evenly coated with ZnO sol in step 2) into a muffle furnace and heat it at a heating rate of 1°C / min to 400°C for 10 minutes, then cool it naturally to room temperature and take it out to obtain ZnO crystal seeds;

[0053] ...

Embodiment 3

[0058] A cadmium sulfide-zinc oxide core-shell multilayer nanorod array photocatalytic material, the preparation method of which comprises the following steps:

[0059] 1) 0.75molZn(Ac) 2 (zinc acetate) and 0.75molC 2 h 7 Disperse NO (ethanolamine) in 50mL of ethylene glycol methyl ether, transfer it to a two-necked flask, pass in inert gas Ar and keep stirring, then place it in an oil bath at 60°C for 30 minutes, and transfer it to an Erlenmeyer flask after cooling to room temperature Medium aging for 24h, to get ZnO sol;

[0060] 2) The obtained ZnO sol is spin-coated onto the clean FTO glass surface by a desktop homogenizer under the condition of low speed and high speed (low speed is 600r / min, high speed is 1300r / min);

[0061] 3) Put the glass sheet evenly coated with ZnO sol in step 2) into a muffle furnace and heat it at a heating rate of 5°C / min to 300°C for 10 minutes, then cool it naturally to room temperature and take it out to obtain ZnO crystal seeds;

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com