High-temperature interlock esterification carbonylation unit for synthesis gas to glycol

A technology of ethylene glycol and interlocking ester, which is applied in the field of industrialized production of synthetic gas to ethylene glycol, can solve the problems of carbonylation reactor explosion and other problems, and achieve the effect of preventing explosion and protecting life safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

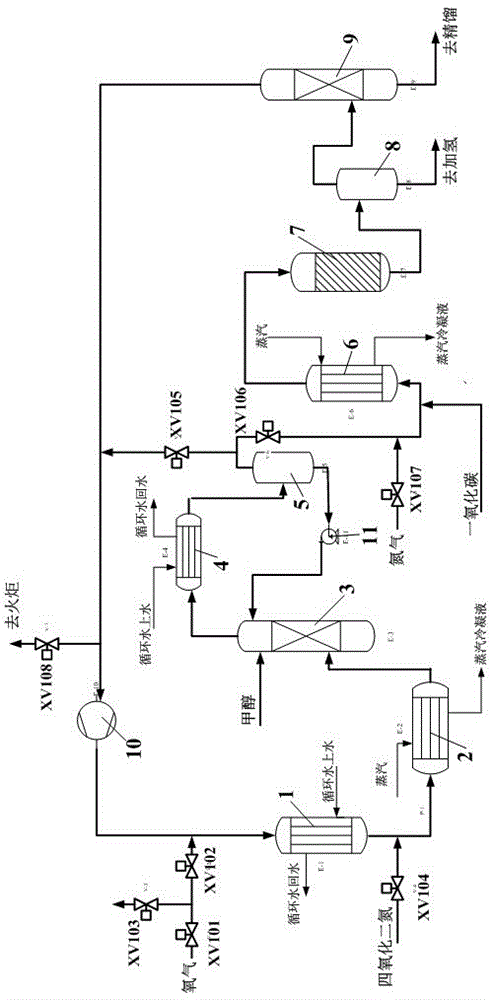

[0012] refer to figure 1 A high-temperature interlocking esterification carbonylation unit suitable for synthesis gas to ethylene glycol is shown, including a compressor 10, a pre-reactor 1, a feed heater 2, a reaction Rectification tower 3, rectification tower condenser 4, rectification tower reflux tank 5, reactor heater 6, carbonylation reactor 7, reactor separation tank 8 and dimethyl oxalate absorption tower 9;

[0013] The liquid phase outlet of the rectification tower reflux tank 5 is connected with the liquid phase inlet at the upper end of the reactive distillation tower 3 through a water pump 11 .

[0014] The pipeline between the compressor 10 and the prereactor 1 is connected to the raw material oxygen pipe through the oxygen emergency shut-off valve XV102 and the outside oxygen shut-off valve XV101 in sequence, and the oxygen emergency shut-off valve XV102 and the outside oxygen shut-off valve XV101 The pipeline is connected with the vent pipe through the oxygen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com