Method for preparing 4,4'-bis(phenyl isopropyl)diphenylamine

A technology of phenylisopropyl and diphenylamine, which is applied in the field of chemical synthesis of antioxidants, can solve the problems of poor catalytic effect of catalysts, achieve the effects of reducing the content of impurities, improving utilization rate, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

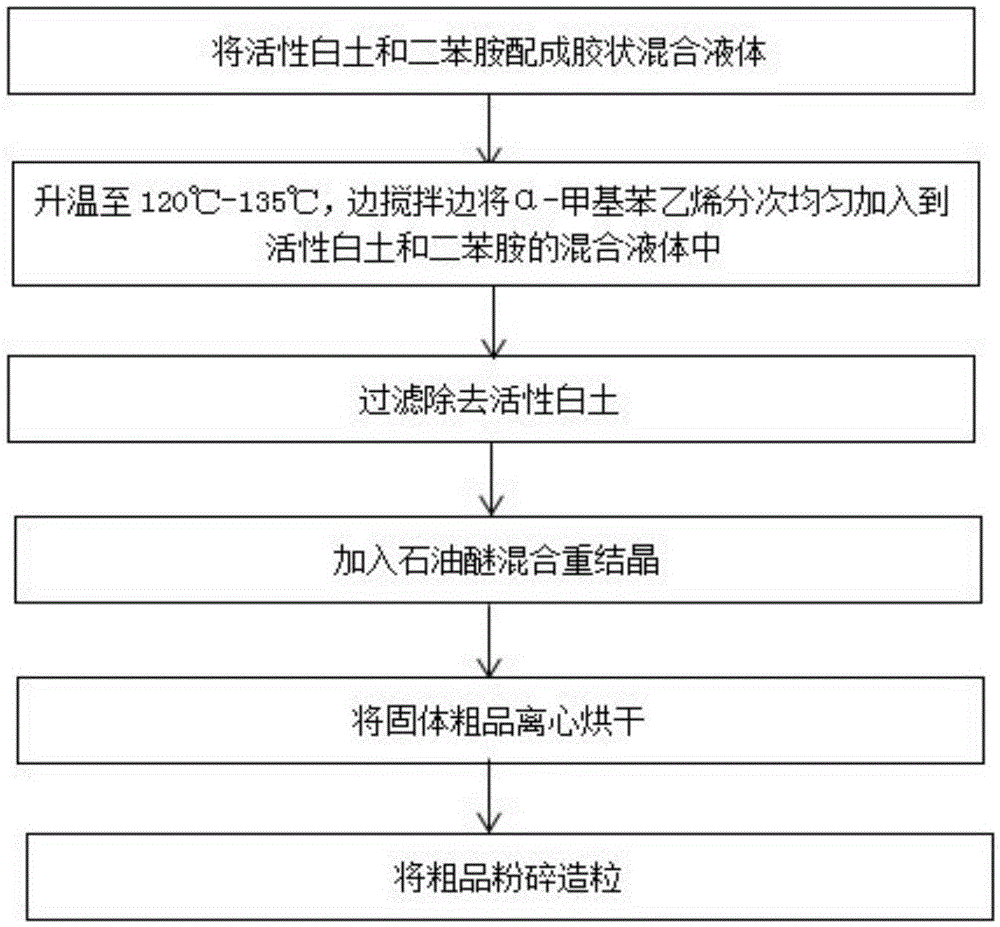

[0029] Refer to the process figure 1 , this specific embodiment discloses a method for preparing 4,4'-bis(phenylisopropyl)diphenylamine, specifically a laboratory preparation of 4,4'-bis(phenylisopropyl)diphenylamine Methods.

[0030] In this embodiment, the weight percentage of activated clay and diphenylamine is 12%, and the molar ratio of diphenylamine to α-methylstyrene is 1:2.0.

[0031] Selection of raw materials and preparation equipment, including diphenylamine (purity ≥ 99.5%), α-methylstyrene (purity ≥ 99%), petroleum ether (analytical pure), activated clay, constant temperature magnetic stirrer, vacuum pump, reflux condensation Device, feeding device, nitrogen protection device, 1L round bottom three-neck reaction flask, thermometer, iron stand, vacuum glass stopper, electric heating mantle, Buchner funnel and other glass instruments.

[0032] Measure 16.9g of diphenylamine and add it to a 1L round-bottomed three-neck reaction flask, weigh 2g of activated clay and...

Embodiment 2

[0037] Refer to the process figure 1 , this specific embodiment discloses a method for preparing 4,4'-bis(phenylisopropyl)diphenylamine, specifically a laboratory preparation of 4,4'-bis(phenylisopropyl)diphenylamine Methods.

[0038] The difference from Example 1 is that the weight percent of activated clay and diphenylamine in this example is 14%, and the molar ratio of diphenylamine to α-methylstyrene is 1:2.4.

[0039] The reaction time for preparing 4,4'-bis(phenylisopropyl)diphenylamine in this example is 0.3 hours shorter than the reaction time for preparing 4,4'-bis(phenylisopropyl)diphenylamine in Example 1.

Embodiment 3

[0041] Refer to the process figure 1 , this specific embodiment discloses a method for preparing 4,4'-bis(phenylisopropyl)diphenylamine, specifically a laboratory preparation of 4,4'-bis(phenylisopropyl)diphenylamine Methods.

[0042] The difference from Example 1 is that the weight percent of activated clay and diphenylamine in this example is 20%, and the molar ratio of diphenylamine to α-methylstyrene is 1:2.6.

[0043] The reaction time for preparing 4,4'-bis(phenylisopropyl)diphenylamine in this example is comparable to the reaction time for preparing 4,4'-bis(phenylisopropyl)diphenylamine in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com