Method for promoting leaching of photocatalysis semiconductor sulfide mineral bacteria by oxalic acid

A semiconductor and photocatalytic technology, applied in the methods of using microorganisms and the improvement of process efficiency, to achieve the effects of improving bacterial leaching efficiency, simple equipment and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

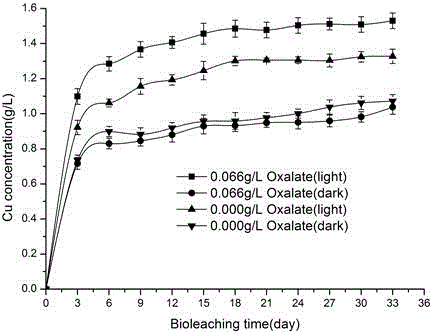

example 1

[0019] The method described in this embodiment mainly proceeds according to the following steps:

[0020] (1) Inoculate 10% inoculum of Thiobacillus ferrooxidans into 100ml of 250ml shaker flask containing 1% chalcopyrite 9K medium for the first acclimatization, and use hemocytometer regularly every day count the number of living cells, when the bacterial concentration can reach 10 8 -10 9 individual / ml, complete the first domestication, remove the slag, centrifuge and collect the bacteria, add the collected bacteria solution to 2% chalcopyrite slurry for domestication, until acidophilic Thiobacillus ferrooxidans can tolerate 2% Chalcopyrite pulp concentration;

[0021] (2) The domesticated acidophilic Thiobacillus ferrooxidans was cultured in shake flasks in 9K medium containing 2% chalcopyrite, the culture conditions were initial pH 2.0, temperature 30°C, shaker speed 170rpm;

[0022] (3) Filter and centrifuge the acidophilic Thiobacillus ferrooxidans cultivated in step (...

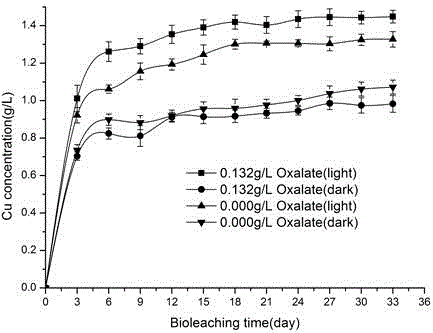

example 2

[0027] The method described in this embodiment mainly proceeds according to the following steps:

[0028] (1) Inoculate 10% inoculum of Thiobacillus ferrooxidans into 100ml of 250ml shaker flask containing 1% chalcopyrite 9K medium for the first acclimatization, and use hemocytometer regularly every day count the number of living cells, when the bacterial concentration can reach 10 9 individual / ml, complete the first domestication, remove the slag, centrifuge and collect the bacteria, add the collected bacteria solution to 2% chalcopyrite slurry for domestication, until acidophilic Thiobacillus ferrooxidans can tolerate 2% Chalcopyrite pulp concentration;

[0029] (2) The domesticated acidophilic Thiobacillus ferrooxidans was cultured in shake flasks in 9K medium containing 2% chalcopyrite, the culture conditions were initial pH 2.0, temperature 30°C, shaker speed 170rpm;

[0030] (3) Filter and centrifuge the acidophilic Thiobacillus ferrooxidans cultivated in step (2), and...

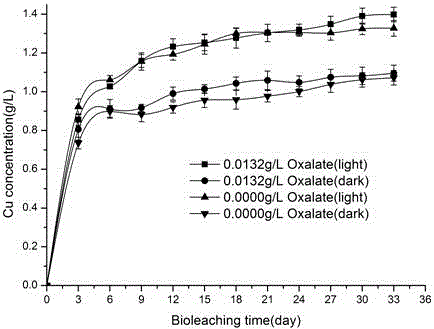

example 3

[0035] The method described in this embodiment mainly proceeds according to the following steps:

[0036] (1) Inoculate 10% inoculum of Thiobacillus ferrooxidans into 100ml of 250ml shaker flask containing 1% chalcopyrite 9K medium for the first acclimatization, and use hemocytometer regularly every day count the number of living cells, when the bacterial concentration can reach 10 9 individual / ml, complete the first domestication, remove the slag, centrifuge and collect the bacteria, add the collected bacteria solution to 2% chalcopyrite slurry for domestication, until acidophilic Thiobacillus ferrooxidans can tolerate 2% Chalcopyrite pulp concentration;

[0037] (2) The domesticated acidophilic Thiobacillus ferrooxidans was cultured in shake flasks in 9K medium containing 2% chalcopyrite, the culture conditions were initial pH 2.0, temperature 30°C, shaker speed 170rpm;

[0038] (3) Filter and centrifuge the acidophilic Thiobacillus ferrooxidans cultivated in step (2), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com