Additive used for improving stainless steel sintered density and method for manufacturing relevant stainless steel sintered component with additive

A technology of sintering density and additives, which is applied in the field of powder metallurgy, can solve the problems of high energy costs and achieve the effect of increasing the pressing density and scientific and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

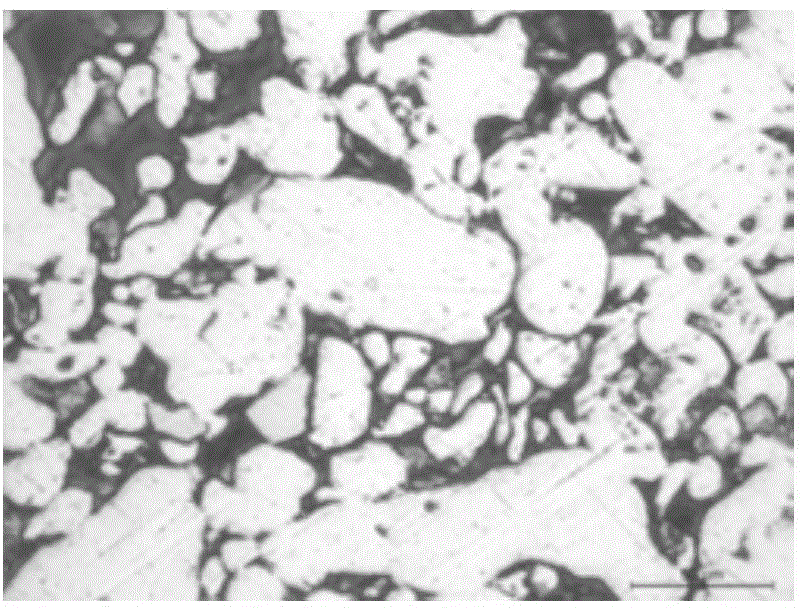

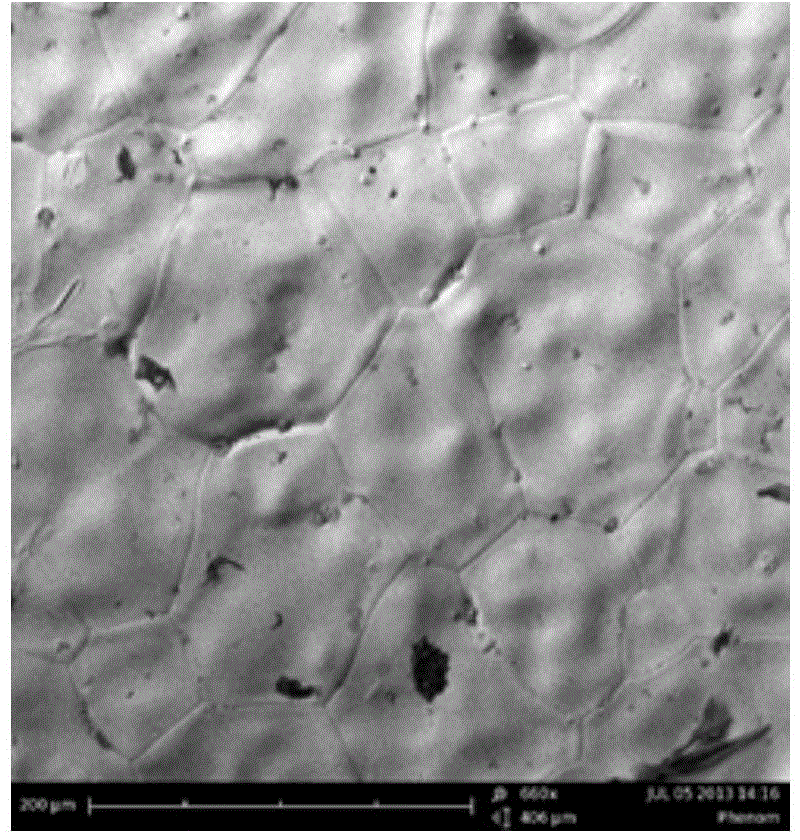

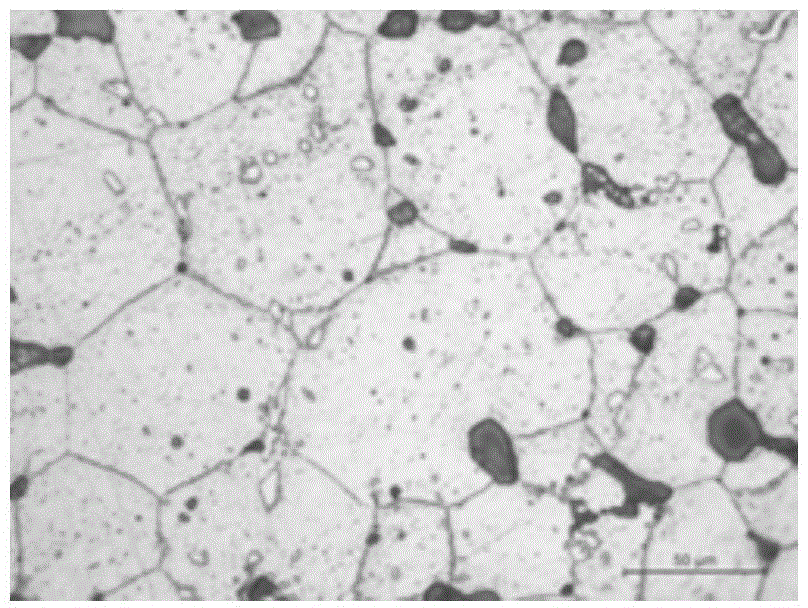

Image

Examples

Embodiment 1

[0026] Use 434L series atomized stainless steel powder as the base powder, add ordinary high-temperature lubricants accounting for 0.4% of the base powder mass, mechanically stir evenly, and use it as a spare material.

[0027] Prepare the additive, the steps are as follows: weigh the required Fe by 3% of the base powder mass 3 P alloy is also based on the quality of the base powder, weighing 0.1% of its mass of lauric acid (abbreviated as LA) and 0.2% of its mass of malic acid (MA), mixed into Fe 3 Into the P alloy powder, drop a small amount of solvent—absolute ethanol, preferably to dissolve MA, stir evenly, and dry to obtain the sintering additive.

[0028] Mix the above-mentioned sintering aid additives into the stainless steel base powder equipped with ordinary lubricants, and mix them in a V-type mixer for 0.5 hours. In this way, the stainless steel powder to be pressed with the lubricating effect of the mold wall is ready to be completed.

[0029] As a comparison, ad...

Embodiment 2

[0036] The 434L series stainless steel powder to be pressed powder configured in Example 1 is pressed and formed with standard impact test bar mold, tensile test bar mold and block density test bar mold respectively, and the pressing pressure is all controlled at 600MPa. Rods were placed in the same batch in an argon-protected vacuum sintering furnace for densification and sintering. The sintering temperatures were 1220°C and 1310°C respectively, and the sintering holding time was 40 minutes. / min. Forced cooling after sintering.

[0037] After the preparation of the above samples is completed, the corresponding density and mechanical analysis test rods are taken to test various performance indicators, and the results are recorded in Table 2 below.

[0038] Table 2434L stainless steel sintering properties and additives

[0039]

[0040]

[0041] Due to the sintering promotion effect of additives, the density of stainless steel sintered body has been greatly improved, s...

Embodiment 3

[0043] Use 316L atomized stainless steel powder as the base powder, add ordinary high-temperature lubricant accounting for 0.4% of the base powder mass, mechanically stir evenly, and use it as a spare material.

[0044] Prepare the additive, the steps are as follows: weigh the required Fe by 5% of the mass of the base powder 3 P alloy, the particle size is 7μm, and the quality of the base powder is also used as the standard. Weigh 0.1% of its mass of lauric acid (abbreviated as LA) and 0.2% of its mass of malic acid (MA), and mix it into Fe 3In the P alloy powder, heat and stir evenly until the organic acid is completely melted and coated on the stainless steel powder, then cool down and dry.

[0045] The 316L stainless steel base powder that has been equipped with ordinary lubricants is mixed with the above-mentioned additives, and mixed in a V-shaped mixer for 0.5 hours. In this way, the preparation of the pressed stainless steel powder is completed.

[0046] In the same w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com