Micro electroforming device with double cathodes vertically rotating

A dual-cathode, micro-electroforming technology, applied in the direction of electroforming, electrolysis process, etc., can solve the problems that flat cathode electroforming cannot be applied, and achieve the effects of reducing the edge effect of electroforming, improving the quality of replication, and reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

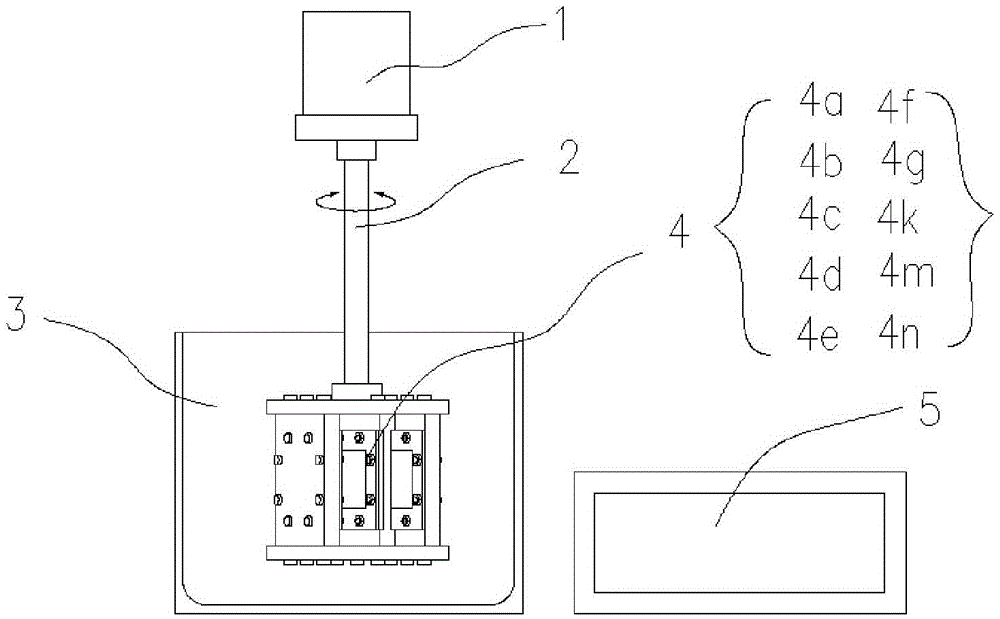

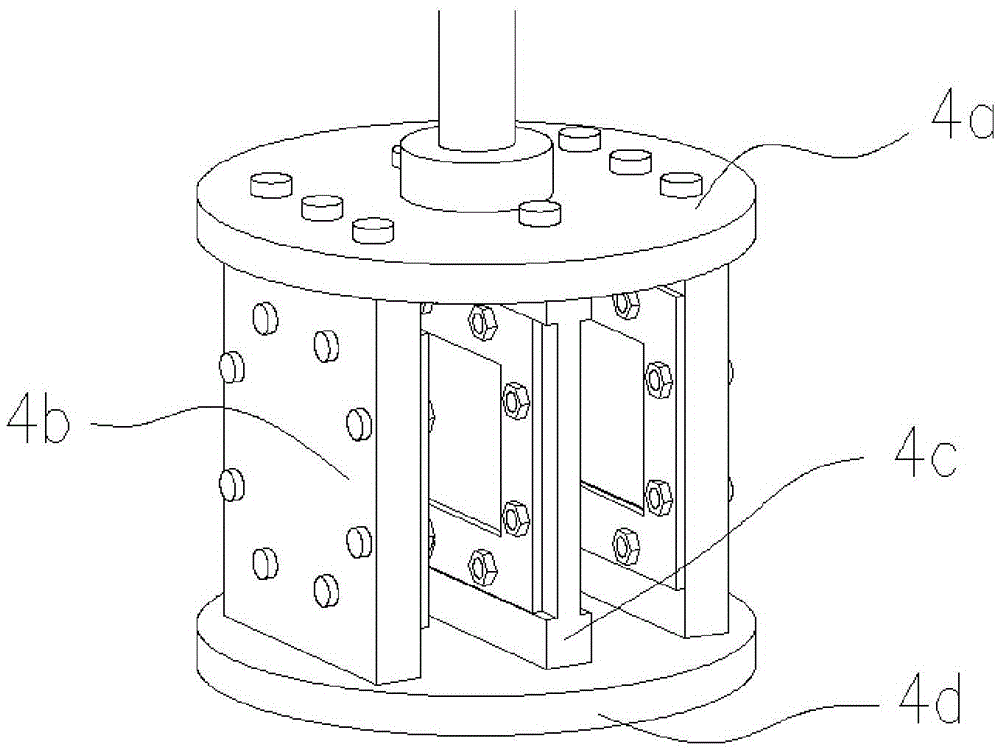

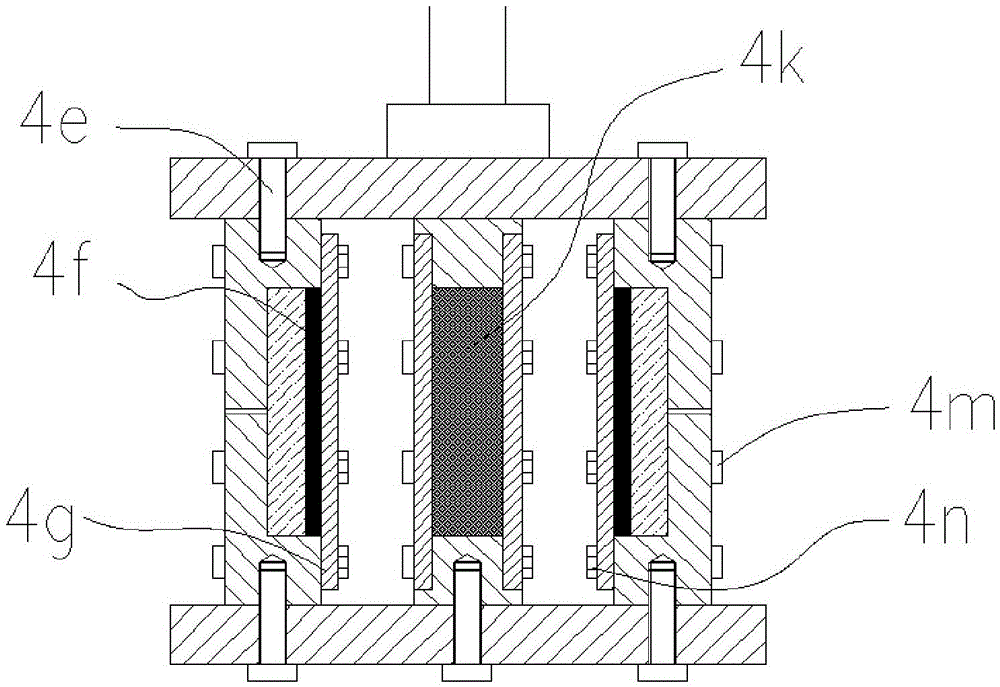

[0026] like figure 1 As shown, the double-cathode vertically rotating micro-electroforming device includes a motor 1 , a vertical rotating shaft 2 , an electroforming tank 3 , a double-cathode clamp unit 4 and a power supply 5 . Motor 1 is a 57 stepper motor, connected to the vertical rotation shaft 2 through a coupling, the front end of the vertical rotation shaft 2 is threaded, and connected to the central threaded hole of the upper fixing plate 4a in the double cathode clamp unit 4, and the rotation of the motor drives the two The cathode clamp unit rotates. The electroforming tank 3 is cylindrical and contains an electroforming liquid, and the double-cathode fixture unit 4 is completely immersed in the electroforming liquid. The power supply 5 adopts a pulse power supply, and the cathode and anode interfaces of the power supply are respectively connected to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com