Infrared axle temperature detection system modulation type probe infrared radiation modulation device and driving method

A detection system, infrared shaft temperature technology, applied in railway vehicle shape measuring instrument, transportation and packaging, single motor speed/torque control, etc., can solve the problems of high cost, high repair rate, poor reliability, etc., and achieve integral saturation Phenomenon suppression, good integral saturation phenomenon, and fast adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

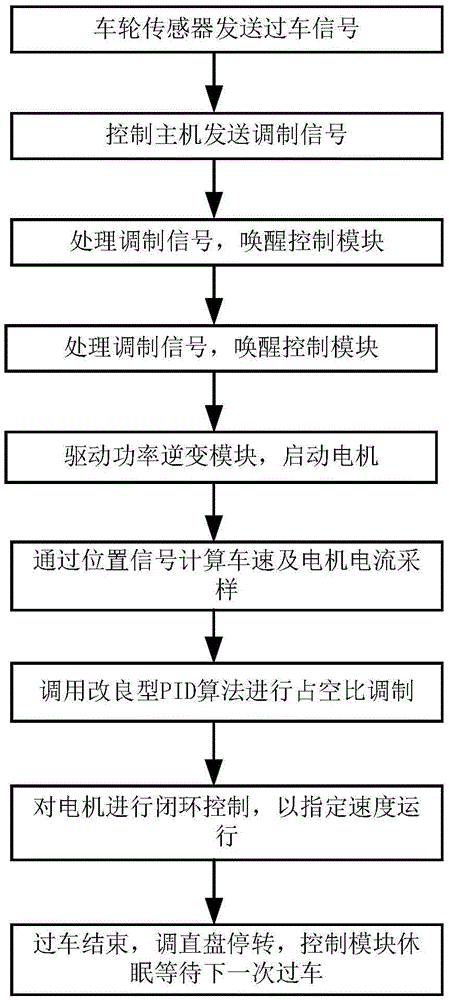

[0023] Further detailed description will be given below in conjunction with the accompanying drawings.

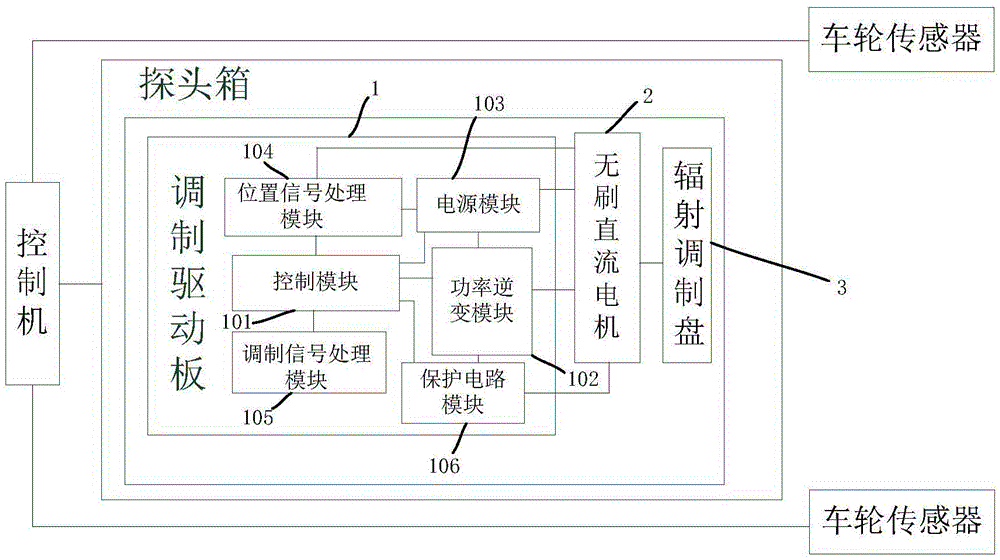

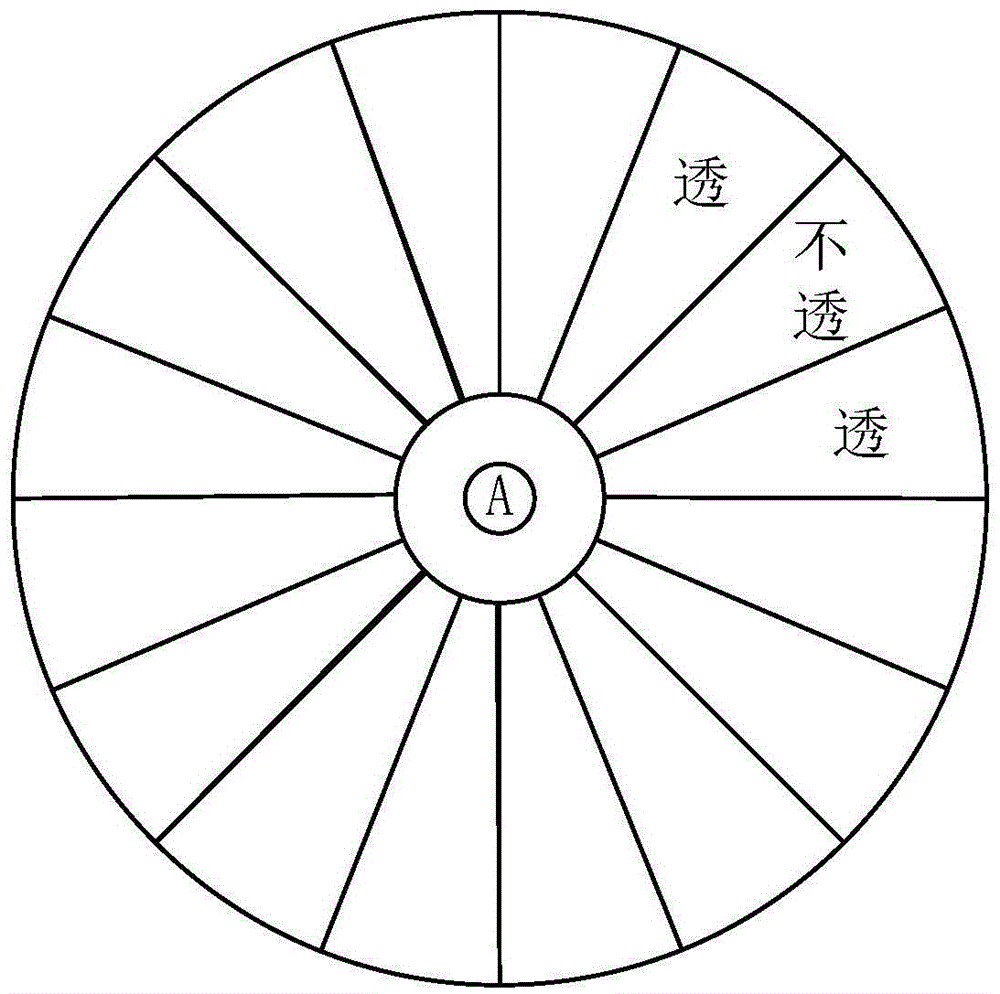

[0024] The infrared shaft temperature detection system driven by the brushless DC motor of the present invention is a modulated probe infrared radiation modulation device, which includes a modulation drive board 1, a brushless DC motor 2 and an infrared radiation modulation disc 3, such as figure 1 shown.

[0025] The modulation driver board 1 consists of a control module 101 , a power inverter module 102 , a power module 103 , a position signal processing module 104 , a modulation signal processing module 105 and a protection circuit module 106 . The modulation driver board 1 consists of a control module 101 , a power inverter module 102 , a power supply module 103 , a position signal processing module 104 , a modulation signal processing module 105 and a protection circuit module 106 . Wherein the control module 101 is connected with the modulation signal processing modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com