Chicken spleen organ hydrolysate and preparation method and application thereof

A hydrolyzate and spleen technology, applied in the field of chicken spleen hydrolyzate, can solve the problems of long production cycle, low added value, single function, etc., and achieve the effect of shortened production cycle, high added value and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

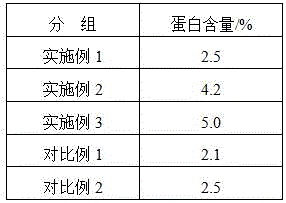

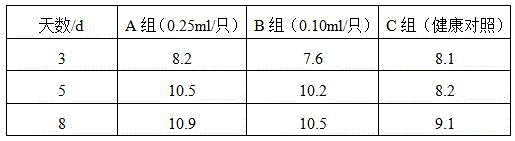

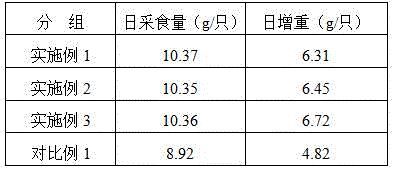

Examples

Embodiment 1

[0029] A preparation method for chicken spleen hydrolyzate, comprising the following steps:

[0030] (1) Clean the chicken spleen with the outer fat, epidermis and subcutaneous fascia removed with purified water, add normal saline at a weight ratio of 1:1, and then add Gur gum and gelatin (ancient The mass ratio of gelatin and gelatin is 1:3), pour it into a colloid mill, shear and grind at 3900r / min for 30s, and obtain a homogenate;

[0031] (2) Take the homogenate into the reactor, add purified water at a volume ratio of 1:1 and mix evenly to obtain a mixed solution, add 4000U compound protease to each 16ml of the homogenate, adjust the pH value of the mixed solution to 6.2, and store it at 50°C Under hydrolysis for 3.5 hours, the hydrolyzate was obtained;

[0032] (3) Centrifuge the hydrolyzate at 3000r / min for 10 minutes, pass the supernatant through a 10KDa hollow fiber ultrafiltration column to remove the complex protease, and obtain an extract, add potassium sorbate ac...

Embodiment 2

[0034] A preparation method for chicken spleen hydrolyzate, comprising the following steps:

[0035] (1) Clean the chicken spleen with the outer fat, epidermis and subcutaneous fascia removed with purified water, add normal saline at a weight ratio of 1:1, and then add Gur gum and gelatin (ancient The mass ratio of gelatin and gelatin is 1:3), pour it into a colloid mill, shear and grind at 3900r / min for 30s, and obtain a homogenate;

[0036] (2) Take the homogenate into the reactor, add purified water at a ratio of 1:1 and mix evenly to obtain a mixed solution, add 3000U of papain to each 16ml of the homogenate, adjust the pH of the mixed solution to 6.2, and hydrolyze at 50°C for 4 hour, collect the hydrolyzate;

[0037] (3) Centrifuge the hydrolyzate at 4000r / min for 5 minutes, pass the supernatant through a 10KDa hollow fiber ultrafiltration column to remove papain, and obtain an extract, add potassium sorbate accounting for 0.01% by weight of the extract to obtain chicke...

Embodiment 3

[0039] A preparation method for chicken spleen hydrolyzate, comprising the following steps:

[0040] (1) Clean the chicken spleen with the outer fat, epidermis and subcutaneous fascia removed with purified water, add normal saline at a weight ratio of 1:1, and then add Gur gum and gelatin (ancient The mass ratio of gelatin and gelatin is 1:3), pour it into a colloid mill, shear and grind at 3900r / min for 30s, and obtain a homogenate;

[0041] (2) Take the homogenate into the reactor, add purified water at a ratio of 1:1 and mix evenly to obtain a mixed solution. According to the ratio of adding papain 4000U and compound protease 2000U to each 16ml homogenate, first add papain to adjust the mixed solution The pH value is 6.0, hydrolyze at 50°C for 1 hour, then add complex protease, adjust the pH value of the mixture to 6.6, continue hydrolysis for 2 hours, and collect the hydrolyzate;

[0042] (3) Centrifuge the hydrolyzate at 4000r / min for 7 minutes, pass the supernatant thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com