Absorption agent for repairing water polluted by cadmium and preparation method of absorption agent

A cadmium pollution and adsorbent technology, which is applied in the field of preparation of nano-iron oxide, can solve the problems of unfavorable large-scale synthesis and application of nano-iron oxide, cumbersome operation, secondary pollution, etc., achieve low production cost, good repair effect, and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

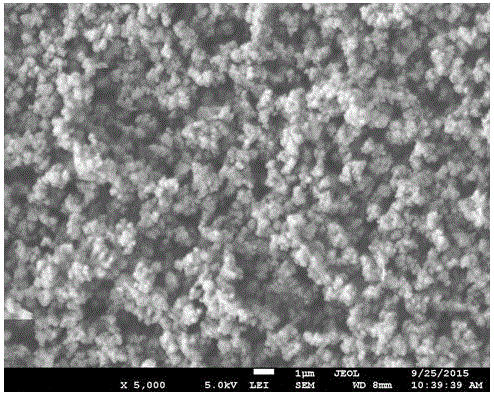

[0026] (1) Fresh laurel leaves are dried at 60°C for 48 hours, crushed through a 5-mesh sieve to obtain laurel leaf powder; weigh 10g of laurel leaves powder, fill them in a nylon mesh bag, and put them into 500ml after the mesh bag is closed Heat and extract in deionized water at 70°C for 1 hour, vacuum filter the extract through a 0.45-micron filter membrane, and collect the filtrate;

[0027] (2) Slowly drop 20ml of 0.2mol / L ferrous sulfate solution into 100ml of laurel leaf extract to make it react, then shake the mixed solution for 1 hour, and at the same time pass through the mixed solution at a flow rate of 20ml / min After the reaction is completed, the mixture is vacuum filtered through a 0.45-micron filter membrane, and rinsed with deionized water until the pH value of the leachate is constant. The resulting solid is dried in a freeze dryer for 10 hours, taken out and ground through a 200-mesh sieve to produce nanometer iron oxide.

Embodiment 2

[0029] (1) Fresh laurel leaves are dried at 70°C for 96 hours, crushed through a 5-mesh sieve to obtain laurel leaf powder; weigh 20g of laurel leaves powder, fill it in a nylon mesh bag, and put it into 500ml after the mesh bag is closed Heat and extract in deionized water at 70°C for 1 hour, vacuum filter the extract through a 0.45-micron filter membrane, and collect the filtrate;

[0030] (2) Slowly drop 20ml of 0.2mol / L ferrous sulfate solution into 100ml of laurel leaf extract to make it react, then shake the mixed solution for 1 hour, and at the same time pass through the mixed solution at a flow rate of 20ml / min Inject compressed oxygen; after the reaction is completed, vacuum filter the mixture through a 0.45 micron filter membrane, and rinse with deionized water until the pH value of the leachate is constant, put the resulting solid in a freeze dryer for 8 hours, take it out and grind it through a 200-mesh sieve to produce nanometer iron oxide.

Embodiment 3

[0032] (1) Fresh laurel leaves are dried at 90°C for 24 hours, crushed through a 5-mesh sieve to obtain laurel leaf powder; weigh 50g of laurel leaves powder, fill it in a nylon mesh bag, and put it into 500ml after the mesh bag is closed Heat and extract in deionized water at 70°C for 1 hour, vacuum filter the extract through a 0.45-micron filter membrane, and collect the filtrate;

[0033] (2) Slowly drop 20ml of 0.2mol / L ferrous sulfate solution into 100ml of laurel leaf extract to make it react, then shake the mixed solution for 1 hour, and at the same time pass through the mixed solution at a flow rate of 20ml / min After the reaction is completed, vacuum filter the mixture through a 0.45-micron filter membrane, and rinse it with deionized water until the pH value of the leachate is constant, put the resulting solid in a freeze dryer and dry it for 12 hours, take it out and grind it through a 200-mesh sieve to produce nanometer iron oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com