Composite (BiO)2CO3/C photocatalyst and application thereof

A catalyst, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of large specific surface area, good hygroscopicity and permeability, good recovery and secondary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

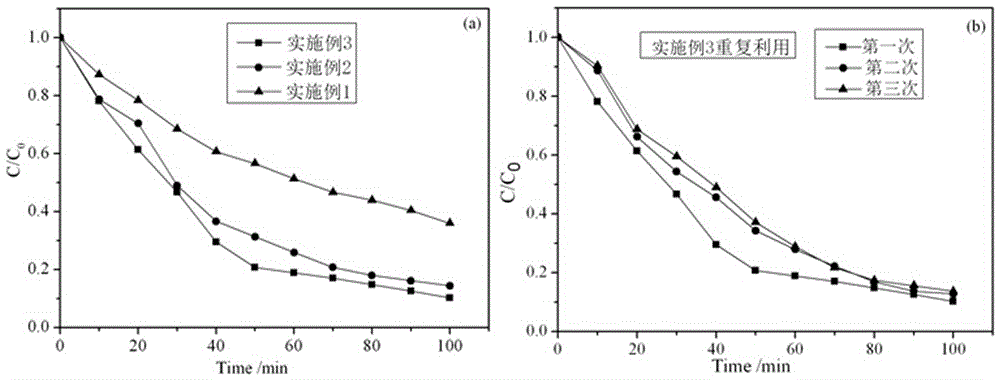

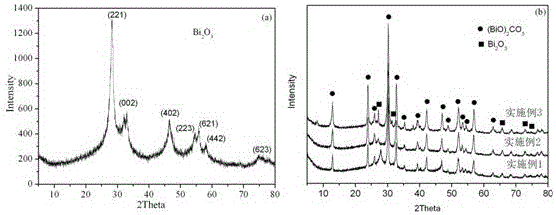

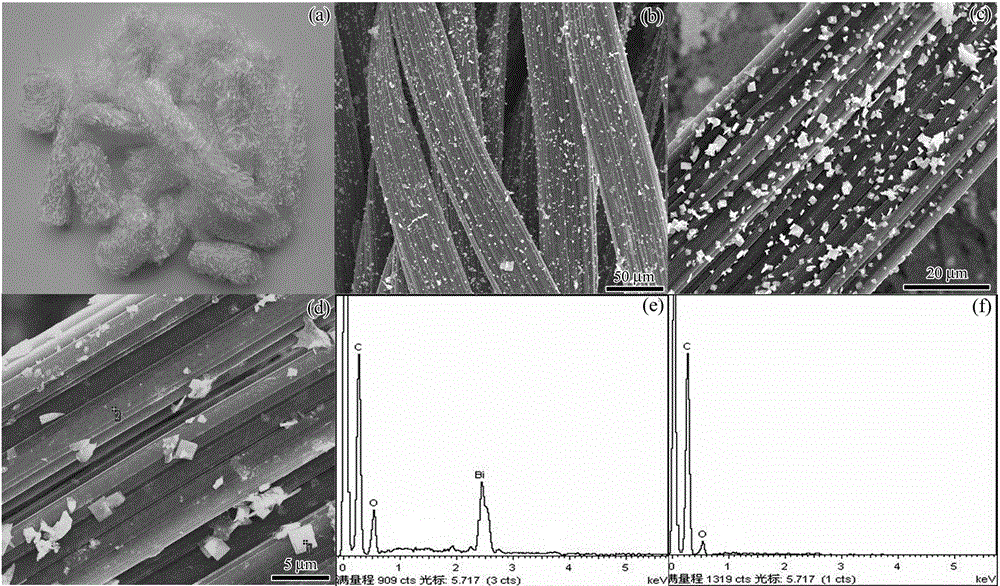

Embodiment 1

[0028] Cut the bamboo fiber into 2cm-long segments, and boil the bamboo fiber in boiling water at 100°C for 30 minutes. The purpose of boiling is to clean the surface of the bamboo fiber so that it will not stick during the subsequent high-temperature carbonization process. After boiling, the bamboo fibers are dried at a temperature of 80°C for 6 hours. Soak the treated bamboo fiber in 0.1mol / L bismuth nitrate solution, the mass ratio of bamboo fiber to bismuth nitrate is 1:15, and the soaking time is 4h. Calcined in a muffle furnace at a temperature of 500°C for 1 hour to obtain carbon fiber-loaded bismuth oxide (Bi 2 o 3 / C). 500mgBi 2 o 3 / C mixed with 100mL of 0.5mol / L sodium carbonate solution, stirred magnetically for 20min, and then put the mixture into a reaction kettle with a reaction temperature of 100°C and a reaction time of 24h. The obtained product was washed with distilled water and ethanol, and then dried at 80°C to obtain (BiO) 2 CO 3 / C composite photo...

Embodiment 2

[0030] Cut the bamboo fiber into 2cm-long segments, and boil the bamboo fiber in boiling water at 100°C for 30 minutes. The purpose of boiling is to clean the surface of the bamboo fiber so that it will not stick during the subsequent high-temperature carbonization process. After boiling, the bamboo fibers are dried at a temperature of 80°C for 6 hours. Soak the treated bamboo fiber in 0.1mol / L bismuth nitrate solution, the mass ratio of bamboo fiber to bismuth nitrate is 1:15, and the soaking time is 4h. Calcined in a muffle furnace at a temperature of 500°C for 1 hour to obtain carbon fiber-loaded bismuth oxide (Bi 2 o 3 / C). 500mgBi 2 o 3 / C mixed with 100mL of 0.5mol / L sodium carbonate solution, stirred magnetically for 20min, and then put the mixture into the reaction kettle, the reaction temperature was 150°C, and the reaction time was 24h. The obtained product is washed with distilled water and ethanol, and then dried to obtain (BiO) 2 CO 3 / C composite photocata...

Embodiment 3

[0032] Cut the bamboo fiber into 2cm-long segments, and boil the bamboo fiber in boiling water at 100°C for 30 minutes. The purpose of boiling is to clean the surface of the bamboo fiber so that it will not stick during the subsequent high-temperature carbonization process. After boiling, the bamboo fibers are dried at a temperature of 80°C for 6 hours. Soak the treated bamboo fiber in 0.1mol / L bismuth nitrate solution, the mass ratio of bamboo fiber to bismuth nitrate is 1:15, and the soaking time is 4h. Calcined in a muffle furnace at a temperature of 500°C for 1 hour to obtain carbon fiber-loaded bismuth oxide (Bi 2 o 3 / C). 500mgBi 2 o 3 / C mixed with 100mL of 0.5mol / L sodium carbonate solution, stirred magnetically for 20min, and then put the mixture into the reaction kettle, the reaction temperature was 190°C, and the reaction time was 24h. The obtained product is washed with distilled water and ethanol, and then dried to obtain (BiO) 2 CO 3 / C composite photocata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com