Spherical cadmium sulfide crystal and preparation method thereof

A cadmium sulfide, spherical technology, applied in the direction of cadmium sulfide, can solve the problems of high cost, low crystallization degree of cadmium sulfide crystal, and low photocatalytic performance, and achieve low cost, easy control, and excellent photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

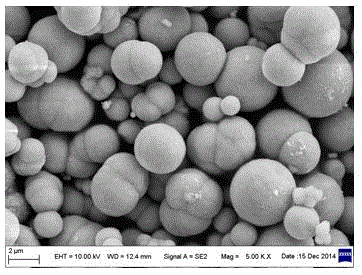

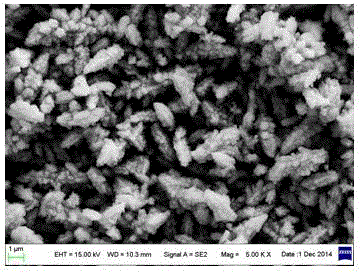

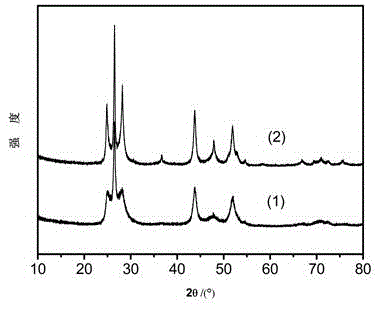

Embodiment 1

[0020] Take cadmium chloride, thiourea and surfactant hydroxypropyl cellulose, prepare mixed solution with cadmium chloride and thiourea with distilled water, the concentration of thiourea is 0.8mol / L, and the concentration of chromium chloride is 0.2mol / L; add the mixed solution to the autoclave, add 0.2g hydroxypropyl cellulose, and the filling degree of the autoclave is 70% (the volume of the autoclave is 100mL, that is, the reaction liquid is 70mL); put the autoclave into Put it into an oven and react at a constant temperature of 180°C for 10 hours; take out the reaction kettle, cool it naturally, wash, centrifuge and dry the reacted solution to obtain spherical cadmium sulfide crystals.

Embodiment 2

[0025] Take cadmium chloride, thiourea and surfactant hydroxypropyl cellulose, prepare mixed solution with cadmium chloride and thiourea with distilled water, the concentration of thiourea is 1mol / L, and the concentration of chromium chloride is 0.2mol / L L; This mixed solution is joined in the autoclave, adds 0.5g hydroxypropyl cellulose, and the filling degree of the reactor is 70%;

[0026] Put the reactor into an oven and react at a constant temperature of 140°C for 16 hours; take out the reactor, cool it naturally, wash, centrifuge and dry the reacted solution to obtain spherical cadmium sulfide crystals.

Embodiment 3

[0028] Weigh cadmium chloride, thiourea and surfactant hydroxypropyl cellulose, prepare mixed solution with cadmium chloride and thiourea with distilled water, the concentration of thiourea is 0.3mol / L, and the concentration of chromium chloride is 0.3mol / L; add the mixed solution to the autoclave, add 0.1g hydroxypropyl cellulose, and the filling degree of the autoclave is 70%;

[0029] Put the reactor into an oven and react at a constant temperature of 200°C for 8 hours; take out the reactor, cool it naturally, wash, centrifuge and dry the reacted solution to obtain spherical cadmium sulfide crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com