In-situ combination method used for surface water black odorous sediment remediation

A black and odorous bottom sludge and combined method technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low adsorption capacity, high price, in-situ pollution of bottom sludge, etc. , to reduce the concentration of total phosphorus and nitrate nitrogen, enhance the adsorption capacity, and achieve the effect of repeated utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

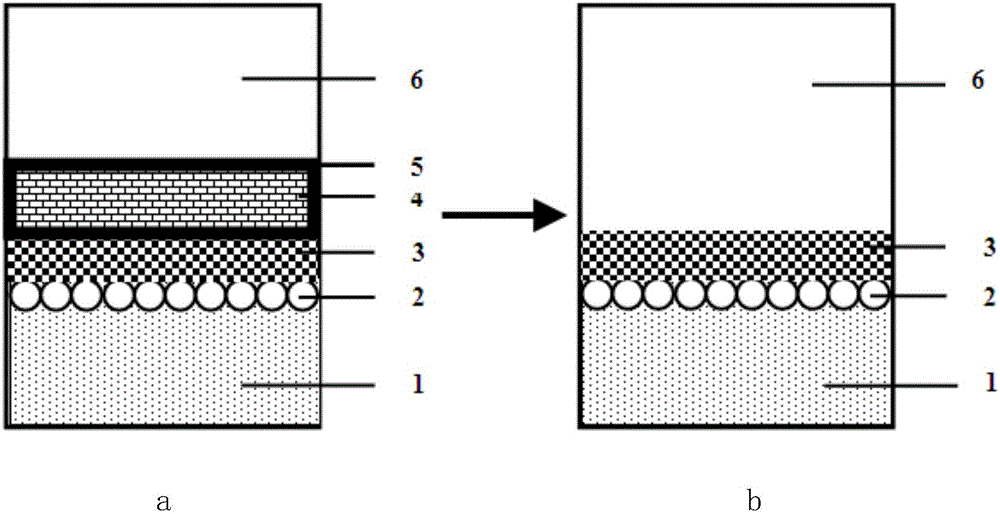

Method used

Image

Examples

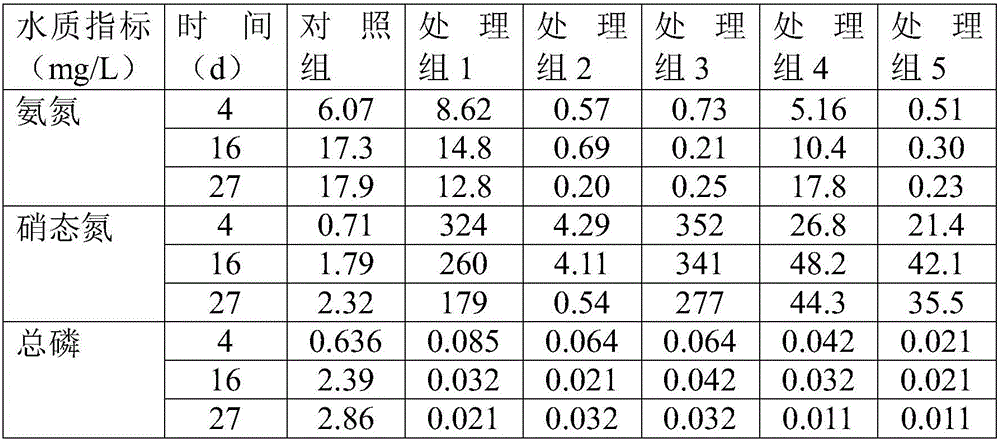

Embodiment 1

[0043] (1) Preparation of zirconium modified zeolite:

[0044] 1. Adopting zirconium oxychloride octahydrate to prepare a zirconium oxychloride solution whose mass concentration is 50g / L;

[0045] ②Weigh the natural zeolite with a particle size of 200 mesh and place it in a container, then take out a zirconium oxychloride solution with a mass concentration of 50g / L and fully mix it with the natural zeolite according to the liquid-solid ratio of 10mL / g;

[0046]③ Adjust the pH of the mixed solution obtained in step ② to 10 with a sodium hydroxide solution having a concentration of 2 mol / L. After the reaction is completed, perform solid-liquid separation, wash, and dry to obtain zirconium-modified zeolite.

[0047] experiment procedure:

[0048] Take 6 2.5L Erlenmeyer flasks, and add 800g of wet sludge to each Erlenmeyer flask. The six Erlenmeyer flasks were treated differently.

[0049] No treatment was added to the first Erlenmeyer flask as a control group.

[0050] Inject...

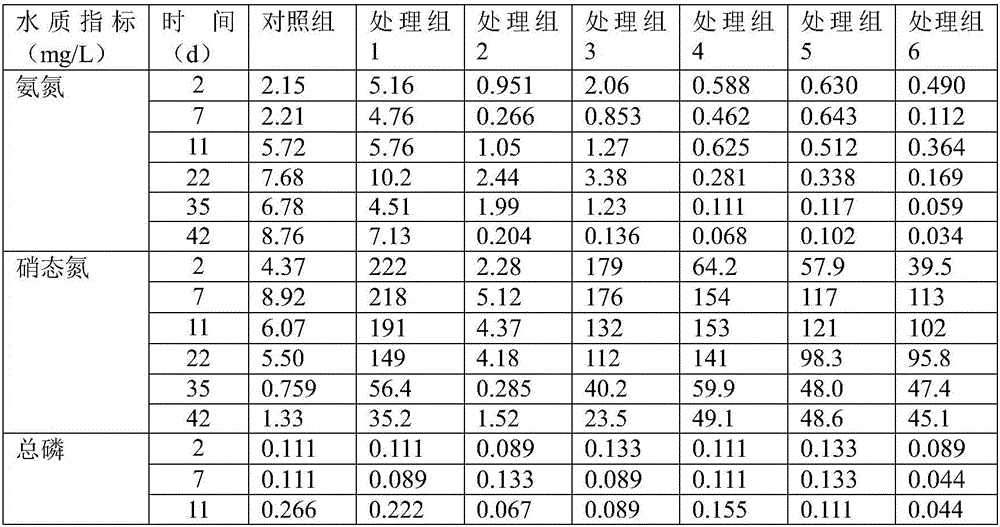

Embodiment 2

[0067] (1) Preparation of zirconium modified zeolite:

[0068] ①Adopt zirconium oxychloride octahydrate to configure a zirconium oxychloride solution with a mass concentration of 50g / L;

[0069] ②Weigh the natural zeolite with a particle size of 200 mesh and place it in a container, then take out a zirconium oxychloride solution with a mass concentration of 50g / L and fully mix it with the natural zeolite according to the liquid-solid ratio of 10mL / g;

[0070] ③ Adjust the pH of the mixed solution obtained in step ② to 10 with a sodium hydroxide solution having a concentration of 2 mol / L. After the reaction is completed, perform solid-liquid separation, wash, and dry to obtain zirconium-modified zeolite.

[0071] (2) Preparation of cationic surfactant modified zeolite:

[0072] ① Take a certain quality of natural zeolite with a particle size less than 0.075mm and place it in a container, then pipette a certain volume of a 25mmol / L cetyltrimethylammonium chloride (CTAC) solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com