Ardealite pavement material and preparation method thereof

A pavement material and phosphogypsum technology, applied in the field of building materials, can solve the problems of weak construction, high construction cost, and small amount of phosphogypsum added, and achieve the effects of low cost, expanding application fields, and relieving environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

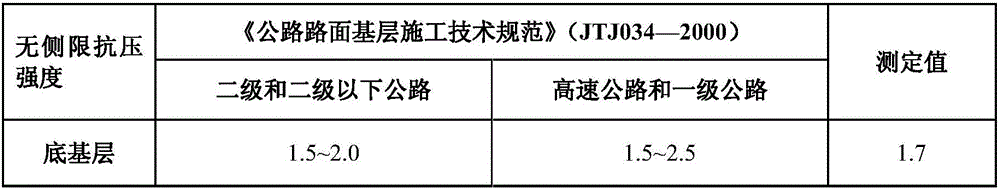

Examples

Embodiment 1

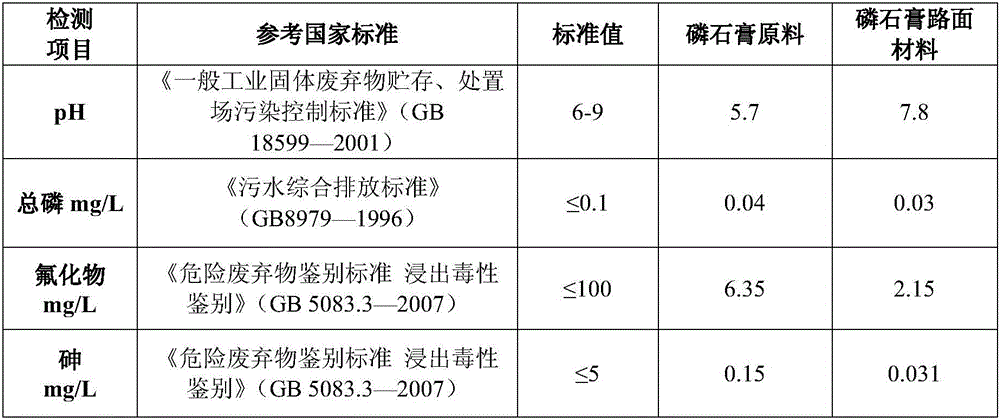

[0032] The phosphogypsum pavement material provided in this embodiment includes the following ingredients in parts by weight: 75-95 parts of phosphogypsum, 4-12 parts of cement, 2-15 parts of water, and 0.02-0.22 parts of curing agent. It can be seen that in this embodiment, bulk industrial solid waste-phosphogypsum is used as the road construction material, and a certain amount of organic / inorganic binder is added to solidify the phosphogypsum, so as to meet the construction conditions of the road surface and make the leached amount of harmful substances meet the environmental protection standard. The preparation method is simple, the cost is low, and the consumption of phosphogypsum is large, which can solve the problem of a large amount of phosphogypsum stockpiling at present, alleviate the environmental protection pressure of phosphorus chemical enterprises, and expand the application field of phosphogypsum; greatly reduce the reserves of phosphogypsum and low tailings ponds...

Embodiment 2

[0037] This embodiment is obtained by further modification on the basis of the first embodiment.

[0038] The phosphogypsum pavement material provided in this embodiment includes the following components in parts by weight: 75-95 parts of phosphogypsum, 4-12 parts of cement, 2-15 parts of water, 0.02-0.22 parts of curing agent, and 0.01-0.05 parts of modifier. share. It can be seen that this embodiment has the same technical effect as that of the first embodiment above, which will not be repeated here. In addition, adding the modifying agent also has the following beneficial effects: the adhesive strength, water resistance and weather resistance of the curing agent can be increased. Further, the modifying agent is one or more mixed solutions of silane coupling agent, sodium lignosulfonate or water glass.

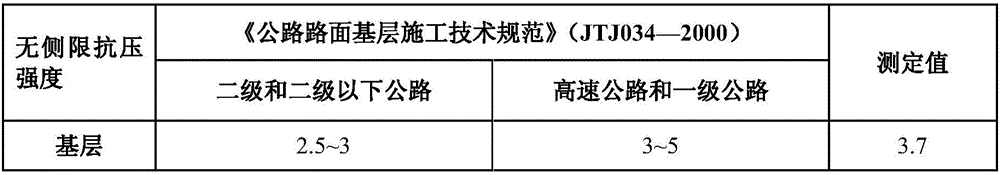

Embodiment 3

[0040] This embodiment is obtained by further detailed refinement on the basis of the foregoing embodiments 1 and 2.

[0041] The phosphogypsum pavement material provided in this embodiment comprises the following ingredients in parts by weight: 94 parts of phosphogypsum with a water content of 14%, 4 parts of road Portland cement with a strength of 42.5 grades, 2 parts of water, 0.2 part of curing agent, modified 0.05 parts of curing agent; wherein, the curing agent includes 92% of copolymerized polyethylene emulsion and 8% of silicone water repellent; the modifying agent includes 100% of sodium lignosulfonate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com