Synthetic method of lithium methoxide

A synthetic method, the technology of lithium methoxide, applied in the direction of metal alcohol preparation, organic chemistry, etc., can solve the problems of excessive residual solvent, easy agglomeration of solid lithium methoxide, and intense reaction between lithium and methanol, so as to achieve less residual solvent and ensure high efficiency Drying, high production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

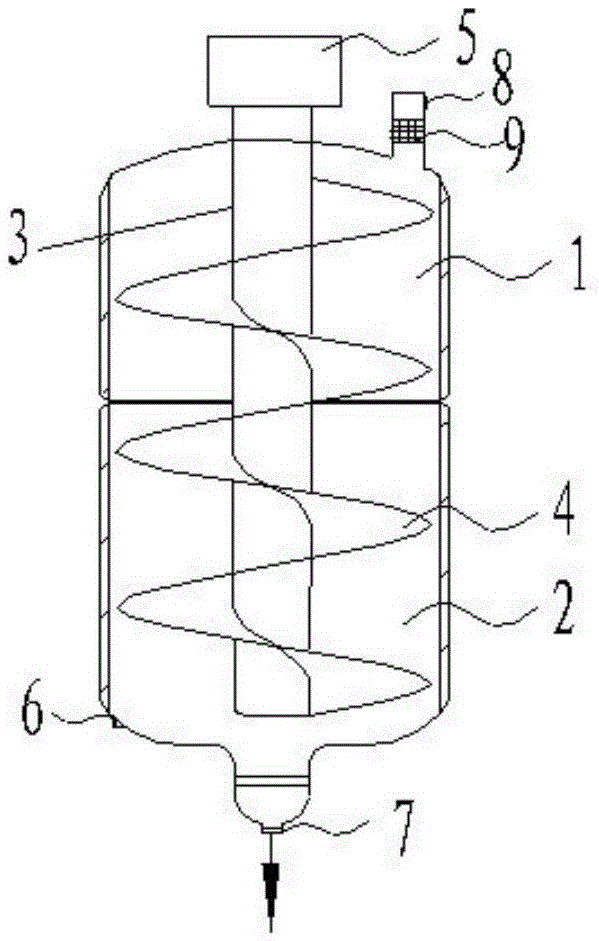

Image

Examples

Embodiment 1

[0053] Step (1): Turn on the jacket to freeze and cool down, replace the reactor with argon for 3 times, then put 300kg of methanol (water content 0.3wt%) from the elevated tank, and add 14kg of lithium sand in batches under the protection of argon, each time 0.5-1kg, the temperature in the reactor is controlled to be lower than 60°C during the feeding process; after the feeding is completed, stir the reaction until the lithium sand is completely dissolved.

[0054] Step (2): reflux for 0.5-1h, distill 150kg of methanol, and concentrate the remaining liquid into a ribbon stirrer (preheated to 50°C) for drying. The stirring speed of the ribbon stirrer is 25rpm. The vacuum degree in the ribbon stirrer is 0.01-0.02MPa. The temperature in the ribbon stirrer was raised from 50°C to 70°C at a rate of 10°C / 30min, and then to 80°C at a rate of 5°C / 30min. After the treatment was completed, 70 kg of white solid powder of lithium methoxide was obtained, without agglomeration, with a pur...

Embodiment 2

[0058] Step (1): Turn on the jacket to freeze and cool down, replace the reactor with argon for 3 times, then put 300kg of methanol (water content 0.3wt%) from the elevated tank, and add 14kg of lithium sand in batches under the protection of argon, each time 0.5-1kg, the temperature in the reactor is controlled to be lower than 60°C during the feeding process; after the feeding is completed, stir the reaction until the lithium sand is completely dissolved.

[0059] Step (2): Reflux for 0.5-1h, distill 200kg of methanol, concentrate the remaining liquid and put it into a ribbon stirrer (preheated to 50°C) for drying. The stirring speed of the ribbon stirrer is 15rpm. The vacuum degree in the ribbon stirrer is 0.07-0.09MPa. The temperature in the ribbon stirrer was raised from 50°C to 70°C at a rate of 15°C / 30min, and then to 80°C at a rate of 10°C / 30min. After the treatment was completed, 68kg of white solid powder of lithium methoxide was obtained, without agglomeration, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com