Ethylene glycol recovery device of polyester wastewater recovery system and ethylene glycol recovery method

A polyester wastewater and recycling system technology, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of poor quality of ethylene glycol products, poor recovery effect, and high viscosity. , to achieve the effect of good equipment stability, reduced polymer probability, and not easy to adhere to the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

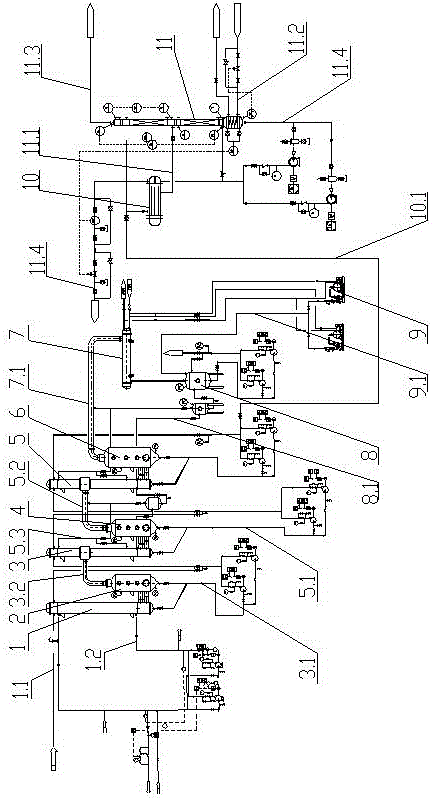

[0037] see figure 1 , the ethylene glycol recovery device of a kind of polyester waste water recovery system that the present invention relates to, it comprises a first-effect heater 1, a first-effect gas-liquid separator 2, a second-effect heater 3, a second-effect gas-liquid separator 4, three Effect heater 5, three-effect gas-liquid separator 6, primary condenser 7, secondary condenser 8, negative pressure vacuum generator 9, heat exchanger 10 and ethylene glycol rectification tower 11.

[0038]Wherein the first-effect heater 1 leads to a first-effect heat medium pipeline 1.2 that goes in and out from the bottom, and the top feed port of the first-effect heater 1 leads to a one-effect heater feed pipe 1.1, and the first-effect heat medium The pipeline 1.2 is used to heat the material entered by the first-effect heater feed pipe 1.1 in the first-effect heater 1. The lower section of the first-effect heater 1 communicates with the lower section of the first-effect gas-liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com