Equipment and method for cooling synthesized gas

A technology for synthesis gas and equipment, which is applied in the gasification process, the manufacture of combustible gas, and the gasification of granular/powder fuels, etc., can solve the problems of high equipment investment and energy consumption, block the synthesis gas channel of waste boilers, etc. The effect of ash, the cost of the device is reduced, and the system is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

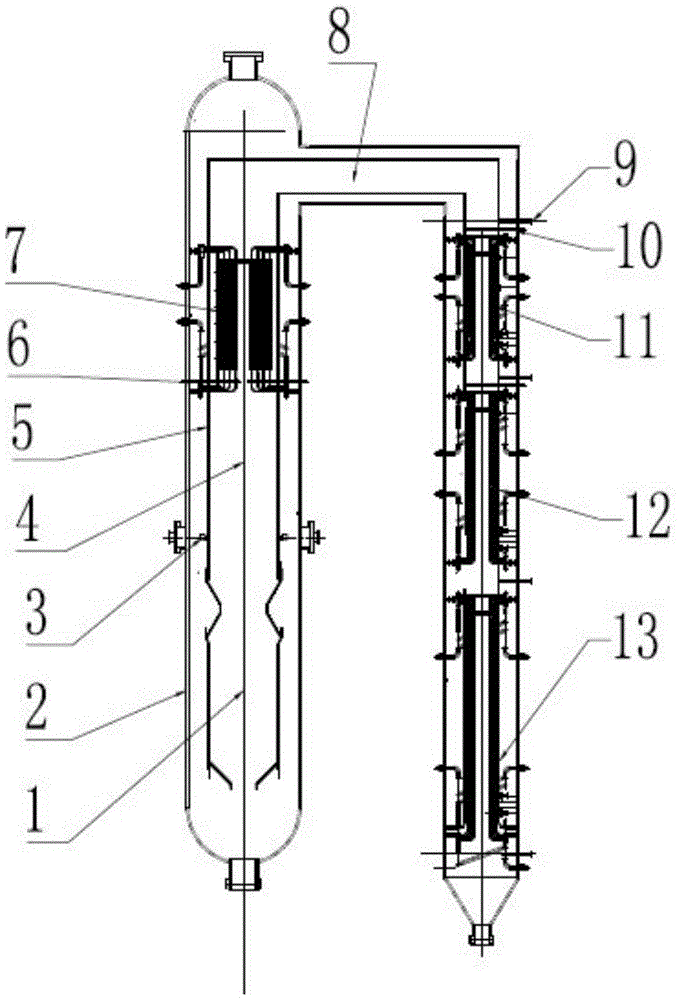

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] Such as figure 1 As shown, a kind of synthesis gas cooling equipment of the present invention comprises radiation waste pot 4 communicating with gasifier 1, and 5 is the water cooling wall of radiation waste pot, the outlet of radiation waste pot 4 is connected to the entrance of high-temperature convection waste pot 7, and the high-temperature convection waste pot The outlet of the pot 7 is connected to a plurality of low-temperature convection waste pots in turn through the conduction section 8, and the outlet of the low-temperature convection waste pot is connected to the low-temperature heat exchanger 13; the bottom of the radiation waste pot 4 is symmetrically and uniformly distributed with multiple nozzles 3 for adding decoking agent; A first soot blower 6 is arranged at the entrance of the high-temperature convection waste pot 7; a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap